How are polymers used in wastewater treatment?

Polymers can be found everywhere. Polymers are found in nearly every product we come into contact with, from a wood desk to plastic water bottles. They're probably in whatever device you're using to read this.

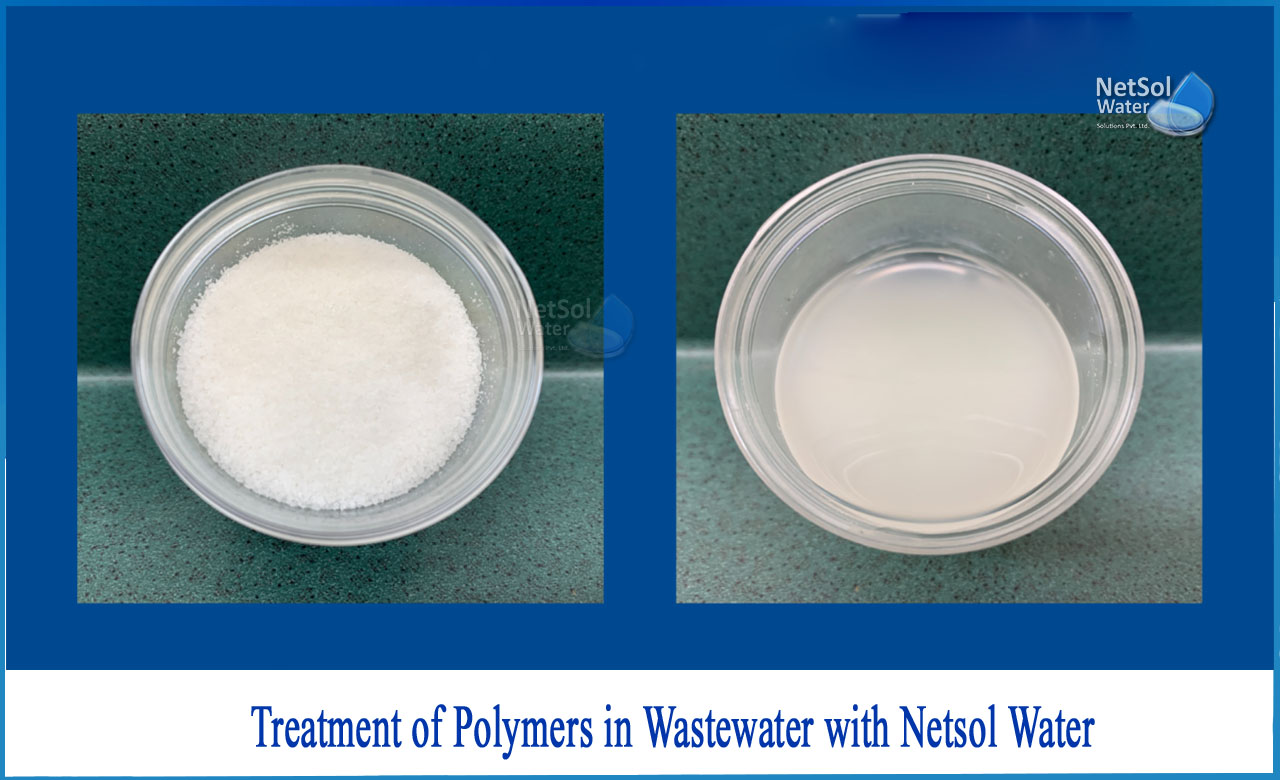

They don't, however, just make products. Water-soluble polymers are commonly used in wastewater treatment to remove suspended solids and/or contaminants. They are commonly used in municipal, industrial, and storm water treatment systems, but many consumers are unaware of their significance.

Polymers are nothing short of amazing. In many cases, polymer solutions can be observed in real-time as solids settle out of liquid suspension. When properly prepared, activated, and applied polymer, liquid/solid separation that once took days or even months when left to gravity alone can now be accomplished in minutes or seconds.

What exactly are polymers?

Polymers are chains of molecules composed of smaller molecules known as monomers. Monomers join together to form a chain, which is referred to as a polymer. One polymer can contain millions of monomer molecules, and the more monomers there are, the longer the polymer chain.

Different monomers will now produce anionic or cationic polymers. Both polymer types settle liquid-suspended solids, but for different reasons.

Anionic polymers, which have a negative charge, are commonly used in applications involving inorganic solids such as clays and silts. Anionic polymers are expected to be used in industrial applications such as sand and gravel production, drilling, mining, and other mineral-based liquid-solid separation.

Cationic polymers, which have a positive charge, are commonly used to settle organic solids such as animal waste or vegetation. Dredging, municipal wastewater treatment plants, food processing, agricultural, and dairy applications all make use of cationic polymers.

The problem with polymers

As with many other products that have found their way into wastewater treatment processes, the demand for expensive polymers is dwindling as wastewater treatment plants shift to more innovative, efficient, and cost-effective solutions. Polymer salespeople will continue to sell polymer products into the wastewater treatment market because the market is so large and because that is what they have available to sell. However, astute plant operators are increasingly aware that polymer products treat the symptoms rather than the underlying causes of wastewater treatment issues.

Many important challenges in industrial applications can be addressed by polymer chemistry, but the process of combining, producing, and deploying polymer products is extremely complex, expensive, and time-consuming. Polymer reduction saves wastewater treatment plants time, money, and labor. When traditional iron-based (ferric) and aluminum-based compounds are used to address the core problem of phosphorus reduction, the use of polymer products is required in wastewater treatment. Although ferric and aluminum-based coagulants are effective at lowering phosphorus levels in wastewater, they open the door to other issues that must be addressed with additional products such as polymers and labor-intensive processes.

What water quality is required?

The quality of water required for the plant is the second most important factor to consider when selecting the best raw water treatment system for the plant.

Is it necessary for drinking water to be pure?

Is ultrapure w?ater required for the production of microelectronics? Is it necessary for water to be so pure for domestic purposes such as flushing a toilet or cleaning equipment?

The quality of the water will be determined by the industry. Many industrial facilities, for example, in the petrochemical, power, refinery, and chemical industries, require large volumes of water for boiler makeup.

As a result, the raw water treatment technologies chosen should ensure that the system properly prepares the water for polishing treatment as well as eliminating colloidal contaminants from the water, which will foul membrane systems and plug deionizers. Specifically, colloidal silica will have an impact on downstream treatment technologies as well as their ability to run efficiently.

By Netsol Water, it is preferable to conduct field pilot testing to validate treatment-technology assumptions and optimize design. Other problems may arise and be traced during this phase prior to selecting the system's components. This can help save a significant amount of plant downtime as well as costly system equipment replacements in the future.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.