What Difference between Sludge incineration and anaerobic digestion?

In this blog we discuss the difference between Sludge incineration and anaerobic digestion.

What is sludge incineration?

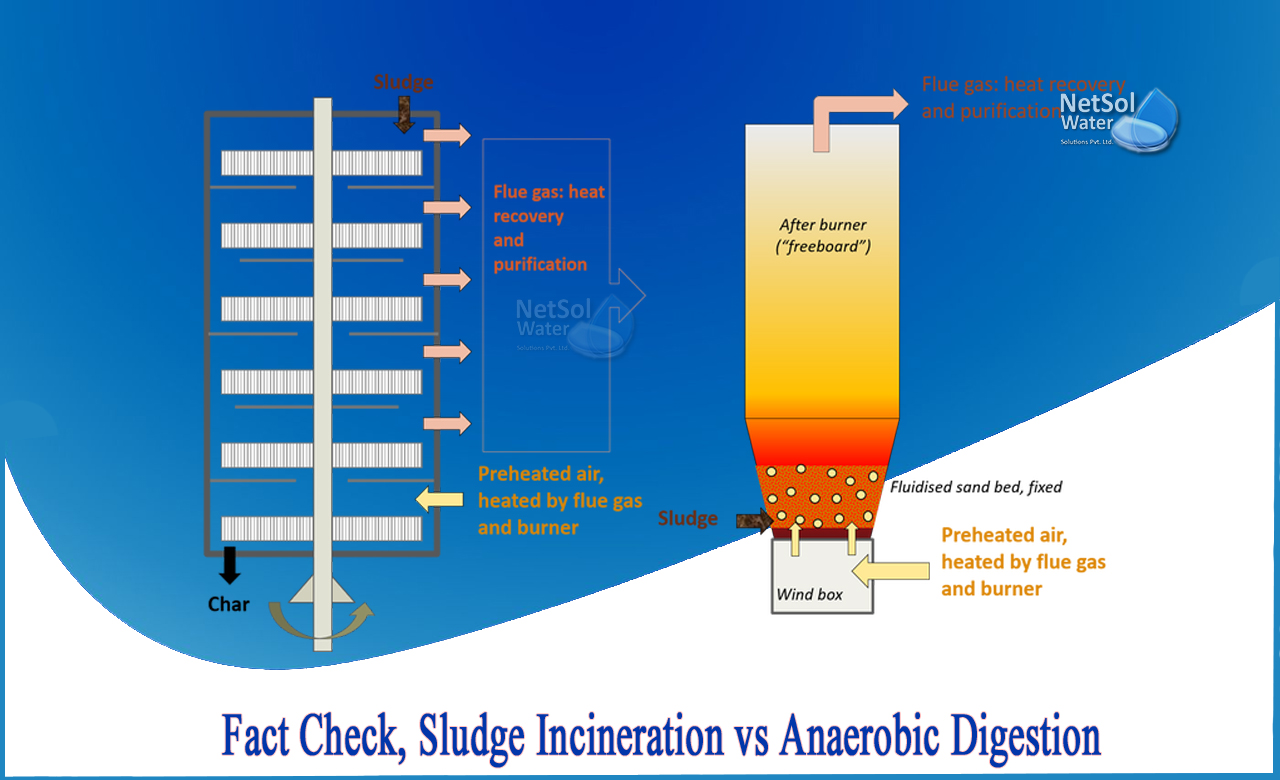

Bio-solids such as municipal sludge, industrial sludge, and fine solids can be incinerated, removing the sludge. The energy recovered from the incineration process can be used to generate green energy. Pre-drying of the sludge and pre-heating of the combustion air may be required depending on the calorific value of the sludge being incinerated.

Incineration is the oldest and most widely used sludge thermochemical treatment process, with the first sewage sludge incinerators installed in the mid-1930s. Hundreds of large sewage sludge incinerators are currently in operation around the world, the majority of which generate power while also converting the sludge to ash.The incineration process is effective at removing feed organics, emits little odor (provided the flue gas treatment is effective), and produces a solid ash product that is stable and reusable. Heat can be recovered from the flue gas stream and reused directly or converted to electrical power.

What is anaerobic digestion?

Anaerobic digestion is a process in which bacteria breaks down organic matter in the absence of oxygen, such as animal manure, wastewater biosolids, and food wastes. Anaerobic digestion for biogas production occurs in a sealed vessel known as a reactor, which is designed and built in a variety of shapes and sizes based on the site and feedstock conditions. These reactors contain complex microbial communities that break down (or digest) waste to produce biogas and digestate (the solid and liquid material end-products of the AD process), which are discharged from the digester.

Co-digestion is the practice of combining multiple organic materials in a single digester. Manure, food waste (processing, distribution, and consumer generated materials), energy crops, crop residues, and fats, oils, and greases (FOG) from restaurant grease traps are all examples of co-digested materials. Co-digestion of low-yielding or difficult-to-digest organic waste can boost biogas production.

Anaerobic digestion vs. sludge incineration:

Both technologies are well-established. The recovery of biogas from AD dates back to the end of the twentieth century: biogas from anaerobic digestion of sewage sludge was used to power Exeter's street lamps as early as the 1890s.

In 1935, an incinerator was installed in Dearborn, Michigan, as the first sludge incinerator plant. This was a fantastic example of technology transfer. The multiple hearth furnace (the patent for which was wisely acquired by Nichols Engineering) was first used in the chemical industry in the 1880s, around the same time that Exeter's gas lamps were connected to a biogas supply. The FBI technology challenge to design is also a classic example of the industry's response to legislative drivers.

So, claiming that incineration is more polluting than AD is, at best, debatable and, in the end, likely to be false if the most modern technologies are used. Both effectively recover latent energy from sludge, both produce a solid residue (from which nutrients can be recovered), and neither is heavily reliant on a fossil fuel energy source.

For more information and design and installation of various waste water treatment plants, contact Netsol Water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.