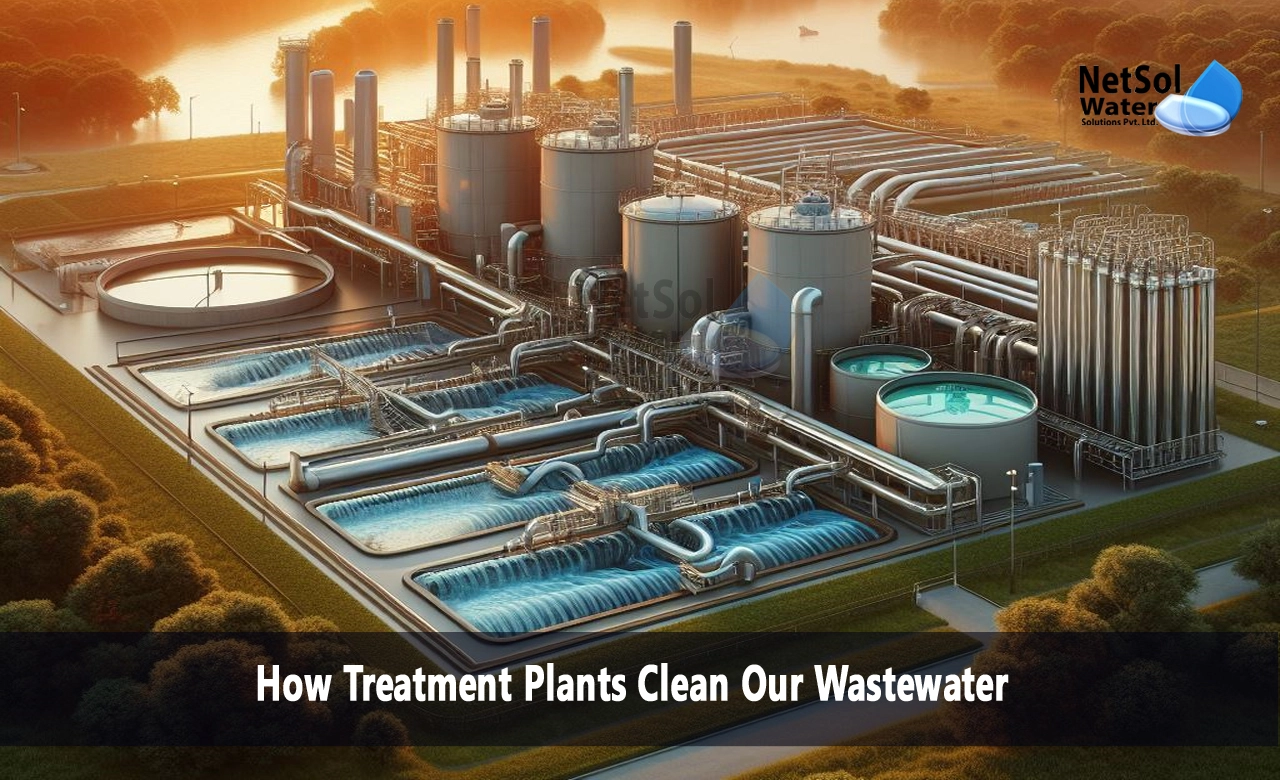

How Treatment Plants Clean Our Wastewater?

Flushing toilets and draining sinks triggers a hidden purification process most take for granted. Yet wastewater treatment plant fascinates those who peer deeper into its mechanized internal workings. Modern municipal plants masterfully clean billions of gallons daily through an orchestrated series of tanks, screens, pumps and protocols unmatched by any individual household or business. Let’s explore what happens after the flush!

Preliminary Screening and Settling

The first treatment stop filters out trash and grit heavier than organics in raw sewage. Bar screens trap floating debris like wipes, rags and sticks. Sand and grit channels settle denser minerals and sediments. Scrapers and pumps remove trapped solids for landfill disposal. Presetting then slows flows to allow lighter grit to fall out in sedimentation tanks. These primary steps prevent later equipment clogging while removing roughly half of incoming solids, oil and grease.

Organics Digestion with Helper Bacteria

Clarified wastewater flows next to aeration tanks full of busy microbial decomposers naturally gorging on soluble organics. Thousands of species of bacteria, fungi, protozoa and rotifers consume nutrition in wastewater, converting sugars, fats and other carbon compounds into basic gases like carbon dioxide. Carefully controlled oxygen levels and ideal growth conditions maximize their waste-munching metabolism. These complex living communities act essentially as digestive systems externally treating the liquid.

Most plants rely on activated sludge configurations where airflow pumps oxygen into suspension, allowing microbes to remove organics in wastewater. Mixed populations flocculate heavier particles while consuming lighter dissolved compounds as fecal clusters and biofilm. After digestion, clarifiers separate cleansed liquid from this biomass. Return pumps recycle active microbes back to aeration tanks while excess growth is pumped to anaerobic sludge digesters.

Advanced Biological Nutrient Removal

Standard secondary treatment removes most organics but not key nutrients like nitrogen and phosphorus that overfeed algae and create eutrophic conditions when discharged. So some plants add tanks selectively encouraging specific “supermicrobes” bioengineered to capture these compounds for growth rather than release metabolites. luxury uptakes during cycling aerobic and anoxic phases force microbes like Nitrosomonas and Tetrasphaera to store excess nutrients as polyphosphates and proteins internally rather than discharge externally into water flows. This microbiological manipulation sustainably extracts otherwise limiting nutrients, preventing eutrophication pollution when cleaned effluent discharges from the plant.

Tertiary Polishing

Following biological processing, effluent may flow through polishing ponds, filters, ultraviolet lamps or chemical treatments for further upgrades. Shallow lagoons allow natural sunlight penetration helping damaging viruses, worms and bacteria. Rapid sand filters screen out nearly all remaining solids above microscopic levels. And UV irradiation mutates DNA/RNA in pathogens. Chlorine, peroxide or ozone oxidation can further disinfect final effluents right before plant outfall into receiving waters, providing multi-barrier protection against trace pharmaceutical or micropollutants getting through upstream processes. Multiple finishing steps ensure purity.

Solids Handling and Resource Recovery

Thickened sludges pumped from clarifiers and digesters require their own dedicated treatment chain. Gravity belt and press filters first dewater solids. Centrifuges and drying beds can further reduce moisture content to cake-like levels for easier handling. Digesters also capture methane gas from anaerobic breakdown, fueling heat and electricity. Incinerators can burn off remaining volatile organics in dried biosolids, reducing mass headed for disposal. Or amendments like lime stabilize solids for agricultural applications on croplands, returning nutrients like nitrogen and phosphorus compounds back to soils rather than wasting managed resources.

The Unsung Heroes of Public Health Protection

Modern municipalities depend fundamentally on wastewater infrastructure largely hidden underground or tucked out of sight. Treatment plants constantly cleanse vast volumes from hundreds of thousands of people reliably and economically day in and out. Their elaborate gear-driven processes control deadly pathogens, extract hazardous compounds and prevent environmental contamination on massive scales unmatched by any individual. Yet like computing clouds and power grids, society takes their silent services for granted. Next time you flush, appreciate the intricate cleansing collaboration orchestrating civilization’s collected wastes!

Conclusion

Municipal wastewater treatment protects public and environmental health by effectively removing contaminants from society’s liquid wastes through integrated physical, biological and chemical process units. Myriad tanks, screens, pumps and protocols filter debris, digest organics, extract nutrients and polish flows down to purity levels safe for receiving waters before discharging cleaned effluents. Concurrent solids capture and resource recovery minimizes residuals requiring ultimate disposal. Treatment plants’ reliable and resilient operations form critical backbones supporting urban density and quality of life. So next time you flush, remember the extensive subsurface infrastructure supporting civilization!

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us know your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-965-060-8473

Or write us at enquiry@netsolwater.com