Why Pretreatment require of RO Plants by Multimedia Filtration?

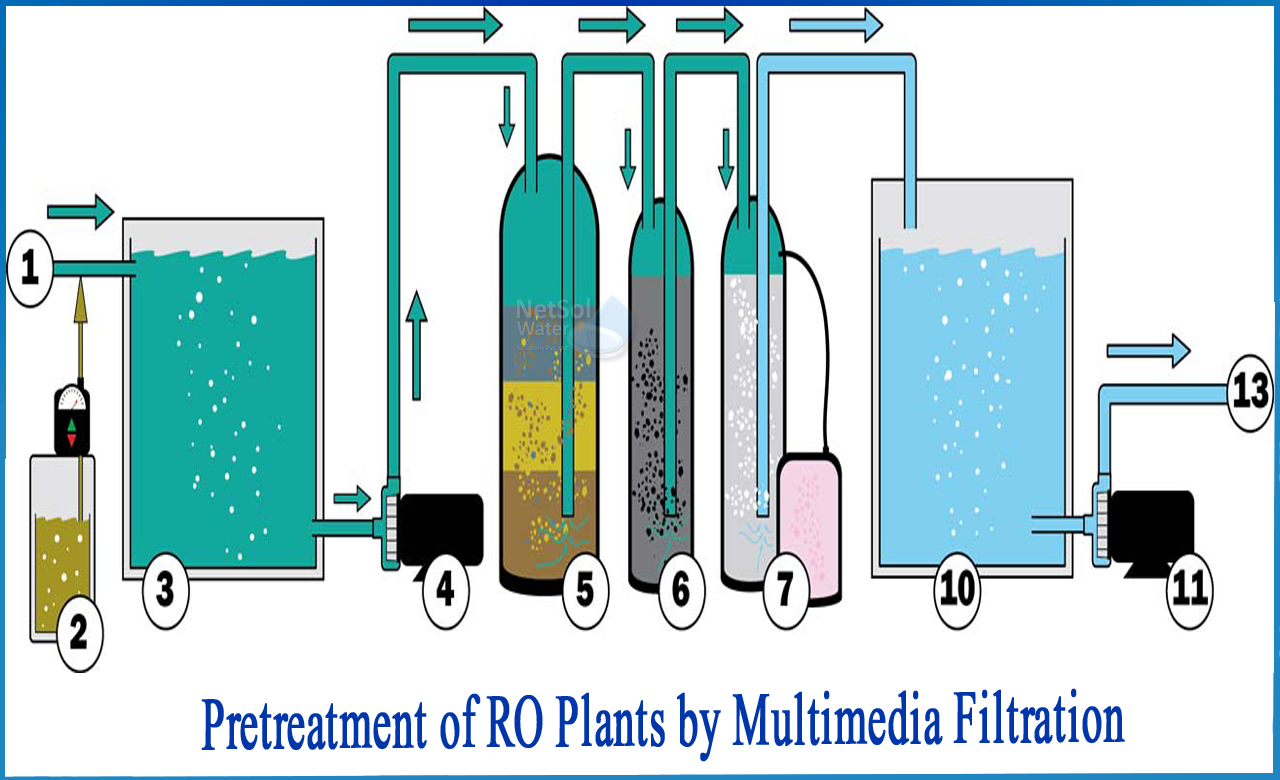

In industrial filtering applications, pressure tanks with sand or other loose material are commonly utilized.

The bed is elevated (or "fluidized") during the cleaning cycle to loosen the filter medium and release trapped debris, which is eliminated in the backwash flow. The bed is allowed to settle after the backwash cycle before the filter is restored to service (i.e., normal flow). Following the settling, a "filter-to-waste" cycle is utilized to ensure that the filtering medium has been suitably re-stratified and that any loose dirt has been removed from the underdrain/ collectors.

But, what about Multimedia Filtration?

In contrast to a "sand filter," which normally employs one grade of sand alone as the filtration media, multimedia filtration refers to a pressure filter vessel that uses three or more distinct media. During the "settling" cycle of a single media filter, the finest or smallest media particles remain on top of the media bed, while the bigger and heavier particles stratify proportionally to their mass down in the filter. As a result, almost all filterable particles are caught at the very top of the filter bed or within 1-2 inches of the top, where the filter media particles have the least space between them.

For multimedia filtration, multi-media water filters generally use three layers of media: anthracite, sand, and garnet. Because of the substantial variances in density, these media are frequently chosen for use in multimedia filters. Anthracite is the lightest per unit volume filtering medium, followed by sand and garnet.

The idea behind using different mass media is that during backwashing, the lightest media with the largest particles (anthracite) will naturally stratify at the top of the filter, while the medium sized media (sand) will settle in the middle, and the heaviest media with the smallest particles (garnet) will settle at the bottom.

Why is it used as a pre-treatment?

The filtration bed's stacking enables the biggest impurities to become caught in the first layer of the filter, with smaller particles sifting farther down into the lower levels. This method of capturing impurities enables for more efficient turbidity removal and longer run periods between backwash cycles.A basic sand filter can be anticipated to remove particles as small as 25-50 microns, but a multimedia filter can remove particles as small as 10-25 microns.

Operating at a larger pressure differential has the potential to force particles so far into the media bed that backwash cannot remove them all. Deep dirt build-up in the filter will result in shortened filter runs and increased differential pressures over time. Air scour may be used in filter backwash to assist remove compacted dirt in the media bed. When this phase is included in the backwash cycle, it is preceded by a "drain down" interval during which water is drained out of the filter vessel.

The perks of Multimedia Filtration over Sand Filters as a pre-treatment option

Multi-media water filters, as opposed to standard sand filters, are made up of three filtration media that are arranged in decreasing porosity. Because of their multi-layer design, multi-media water filters can trap and retain far more particles than traditional sand filters before backwashing is required.

Because multi-media water filters trap silt and particles across the whole depth of the filter bed, they may run for considerably longer lengths of time than traditional sand filters. The multimedia filtration technique generates high-quality filtered water at substantially quicker flow rates than standard sand filtration.

What do we offer?

Netsol Water is a renowned producer of water and wastewater treatment plants. Based on client feedback and quality, we are the most demanding organization in the Water industry. We have a reputation for being the Top Commercial RO plant manufacturer, Industrial RO plant manufacturer, Sewage treatment plant manufacturer, and effluent treatment plant manufacturer. Aside from that, our USP is 24x7 customer assistance.

For further assistance, inquiry, or product-purchase-related questions, call us at +91-9650608473 or email at enquiry@netsolwater.com.