Effluent treatment plant for Textile industry

If you work in the industrial sector, you must be concerned with wastewater management. With the rapid development of industry, an increasing number of dangerous pollutants/contaminants are released into the environment, posing substantial environmental risks, particularly water pollution, which is a major worry. The textile sector is the most water-intensive and produces the most effluent. As a result, setting up an effluent treatment plant to limit harmful wastewater discharge from the textile or garment business is required (ETP).

Textile and garment industries produce effluents with a wide range of chemical compositions, so a wastewater treatment system is essential.

Yes, an ETP, or Effluent Treatment Plant, is the finest solution for keeping the environment safe from textile waste, because it saves money and the environment while providing excellent treatment efficiency.

What is effluent treatment plant in textile industry?

An ETP, or Effluent Treatment Plant, is the most effective and technologically sophisticated treatment system for effluent or waste generated by diverse establishments such as industries. The various components of the ETP will be determined by the effluent's characteristics, i.e. the type of effluent to be processed. Depending on the effluent's quality and quantity, numerous types of ETPs are available.

The textile business generates a large volume of wastewater with a wide range of compositions and chemicals used in dyeing, printing, and other processes. Textile companies' discharge of untreated effluent is extremely damaging to the environment, polluting adjacent water and land. An ETP, or effluent treatment plant, helps to solve this problem by safeguarding the environment from the negative effects of wastewater in the textile and garment industries.

The following is a list of the treatment processes used in ETP for the textile industry:

Untreated textile effluent contains significant quantities of TSS, dyes, chemicals & auxiliaries, metal toxicants, and BOD, and must be treated before being discharged into the environment. Pollutants are removed from wastewater as it goes through the ETP, and the water quality is enhanced to an acceptable/standard level, allowing for safe ultimate discharge to the environment.Physical, chemical, and biological mechanisms are frequently used combined in ETP.

In general, an effluent treatment plant has four levels of treatment, which are briefly outlined below in order:

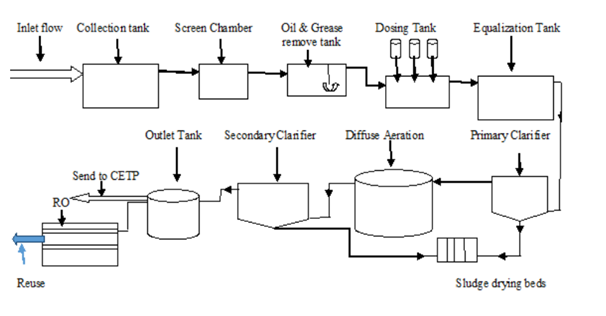

Flowchart for the above process involved is shown below

1. Preliminary treatment:

Often known as pretreatment, is a physical method of treating wastewater. It entails screening, which involves using bar screens to remove big solids such as rags, cloth, yarn, lint’s, twigs, and other debris that could harm the plant's equipment. The waste water is next exposed to the physical treatment stage.

2. Primary Treatment:

It entails physical and chemical techniques for wastewater treatment. When wastewater is pumped into the primary tank, it remains there for a long period, causing heavier particles to settle to the bottom and lighter particles to float to the top. Flocculation and coagulation are used to remove settled and floatable debris, and the water is then sent to a secondary or biological treatment.

3. Secondary Treatment:

Wastewater entering the secondary tank is free of physical particles and is subjected to a biological process. Most ETPs use biological treatment to remove BOD, which includes aerated lagoons, activated sludge, trickling filters, and oxidation ponds, but the activated sludge process is the most versatile biological oxidation method used for wastewater treatment. Approximately 80% of organic waste will be eliminated here, followed by tertiary treatment.

4.Tertiary Treatment:

Physical, chemical, and biological mechanisms are used to remove remaining suspended solids, dissolved solids, and other contaminants that were not eliminated during the previous treatment steps. Several disinfection agents, such as chlorine, ozone, and UV radiation, are commonly utilized depending on the wastewater quality. After this treatment, the wastewater is ready to be disposed of or reused.

Chemicals generated from textile sector cannot be directly disposed of to water as it will harm environment, human and aquatic life. It becomes essential to install treatment plants to remove such contaminants from waste water.

In all the regards of water treatment, Netsol Water can prove a helping hand.