What is Secondary Treatment in Sewage Treatment Plant?

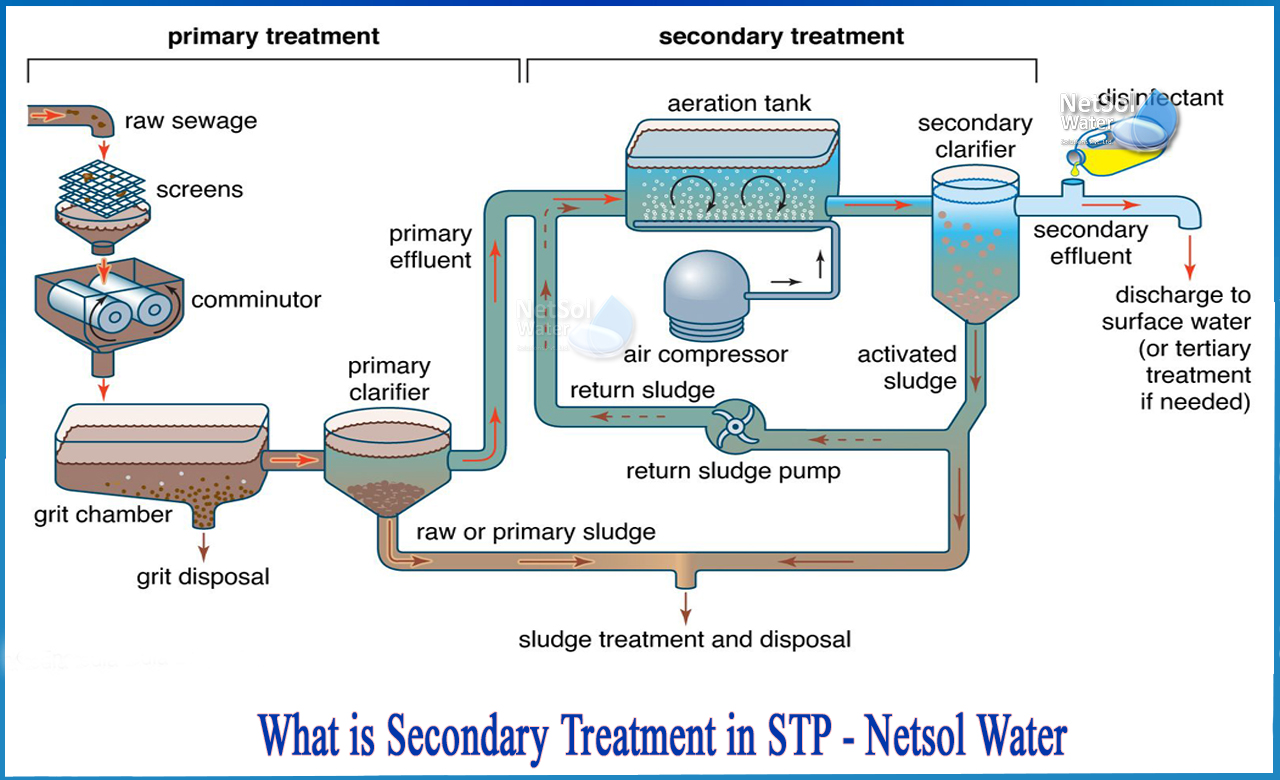

Primary settling eliminates approximately half of the particles and one-third of the BOD from raw sewage. The removal of biodegradable organic materials (in solution or suspension) and suspended particles is referred to as secondary treatment. Disinfection is frequently included in the scope of traditional secondary therapy. Some sanitary engineers consider biological nutrient removal to be secondary treatment, while others consider it to be tertiary treatment.

The wastewater may be referred to as secondary-treated wastewater after this type of treatment.

The Purpose of Secondary treatment:

The goal is to attain a specified level of effluent quality in a sewage treatment facility that is appropriate for either disposal or reuse. Physical phase separation is used to remove settleable materials in a "primary treatment" procedure that frequently precedes secondary treatment. Biological processes are utilised in secondary treatment to remove dissolved and suspended organic materials, which is assessed as biochemical oxygen demand (BOD).

Process types of Secondary treatment:

Secondary treatment systems are classified as fixed-film or suspended-growth systems, and as aerobic versus anaerobic.

Fixed-film or attached growth systems include trickling filters, constructed wetlands, bio-towers, and rotating biological contactors, where the biomass grows on media and the sewage passes over its surface. The fixed-film principle has further developed into moving bed biofilm reactors (MBBR) and Integrated Fixed-Film Activated Sludge (IFAS) processes.

Suspended-growth systems include activated sludge, which is an aerobic treatment system, based on the maintenance and recirculation of a complex biomass composed of micro-organisms (bacteria and protozoa) able to absorb and adsorb the organic matter carried in the wastewater. Constructed wetlands are also being used. An example for an anaerobic secondary treatment system is the up-flow anaerobic sludge blanket reactor. Microorganisms carry out these actions in a controlled aerobic or anaerobic manner, depending on the treatment technology.

Secondary treatment is commonly employed in sewage treatment and is also applicable to a wide range of agricultural and industrial wastewaters.

- Fixed- film treatment:

Filter beds: Trickling filter beds are employed in older facilities and those that receive fluctuating loadings, where the settled sewage liquor is distributed across the surface of a bed consisting of coke (carbonised coal), limestone chips, or specifically created plastic media.

Rotating biological contactors (RBC):A rotating biological contactor (RBC) is a biologically remedied treatment technique used in secondary wastewater treatment after initial treatment. The RBC method exposes wastewater to a biological film in order to remove contaminants before discharging the treated wastewater to the environment, which is often a body of water (river, lake or ocean).

Wetlands:A constructed wetland (CW) is a man-made wetland that is used to treat sewage, grey-water, storm-water runoff, or industrial wastewater. It may also be intended for land reclamation following mining or as a step toward compensating for natural areas lost due to land development. Constructed wetlands are built systems that utilise natural processes such as plant, soil, and organisms to clean wastewater. Constructed wetlands have been employed in both centralised and decentralised wastewater systems.

- Systems of Suspended Growth:

Activated sludge: Activated sludge is a popular suspended-growth secondary treatment technique. Activated sludge plants use dissolved oxygen to stimulate the formation of biological floc, which significantly eliminates organic waste.

Sequencing batch reactors:A cyclic activated sludge (CASSBR) or sequencing batch reactor is one type of system that combines secondary treatment and settling (SBR). Activated sludge is often combined with raw incoming sewage before being mixed and aerated.

Package plants:There are many different types of package units, many of which serve small towns or industrial plants. These plants may utilise hybrid treatment technologies, such as aerobic sludge, to treat incoming sewage.

Membrane bioreactors (MBR):Membrane bioreactors (MBR) are activated sludge systems that use a liquid-solid phase separation membrane. The membrane component avoids the need for a secondary clarifier or filtration by employing low pressure microfiltration or ultrafiltration membranes. The method allows bioreactors to operate at much greater mixed liquor suspended solids (MLSS) concentrations than CAS systems, which are restricted by sludge settling.

For more information, contact Netsol Water.