How Chlorine Disinfection Works?

When it comes to disinfecting wastewater before discharge or reuse, chlorine remains one of the most widely used and effective methods employed by municipal and industrial treatment plants around the world. The process of chlorination has been used for over a century to inactivate harmful pathogens present in wastewater, destroying bacteria, viruses, and other microorganisms that can threaten public health and the environment. Let's take a closer look at how chlorine disinfection works, and the important factors involved in its successful implementation.

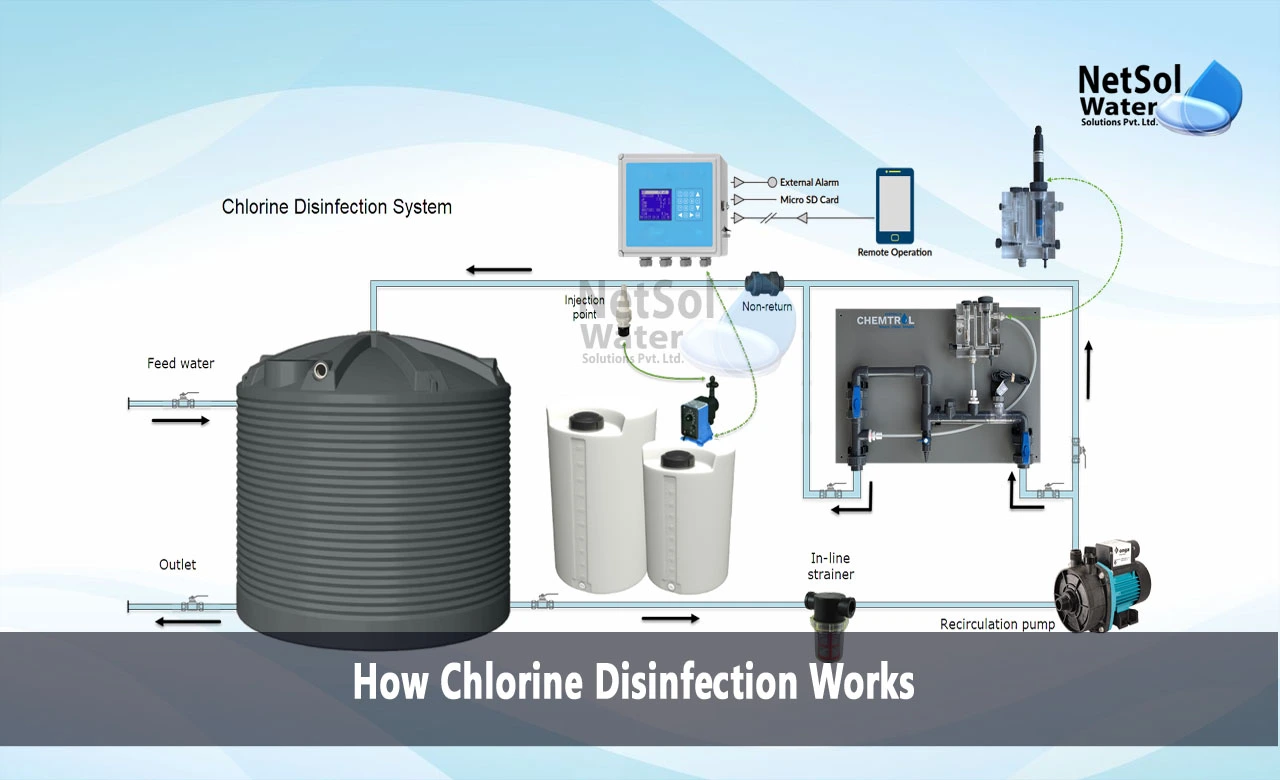

The Chlorination Process

Chlorine disinfection is typically one of the final treatment steps applied to wastewater after undergoing preliminary, primary, and secondary treatment processes. There are three main ways that chlorine is introduced into the wastewater stream:

1. Gas chlorination - Chlorine gas (Cl2) is transferred from liquid or gaseous chlorine cylinders or tanks and diffused into the wastewater flow. Chlorinators are used to meter the flow of chlorine gas, which is then mixed with the wastewater stream through specialized chlorine contact basins or pipeline injectors.

2. Hypochlorite solution feed - Liquid sodium hypochlorite (NaOCl) or calcium hypochlorite (Ca(OCl)2) solutions can be prepared and dosed directly into the wastewater stream. These concentrated liquid bleach solutions are more stable than gaseous chlorine but need to be purchased and stored properly.

3. On-site hypochlorite generation - Some facilities have the capability to generate hypochlorite solutions on-site by running an electrolytic process using salt, water, and electricity to produce a sodium hypochlorite solution. This eliminates the need to receive and store chlorine gas or hypochlorite solutions.

Regardless of the chlorine dosing method, the key is to achieve adequate mixing and contact time in the wastewater stream to allow the chlorine to effectively inactivate the target pathogens present. Typical chlorine contact times range from 15-30 minutes at the low end up to an hour or more depending on the required degree of disinfection, initial pathogen levels, chlorine dosage, and other factors.

Chlorine Dosage and Residual

The amount of chlorine dosed into the wastewater stream is critical and depends on several wastewater characteristics including:

1- Initial microorganism and pathogen concentrations

2- Ammonia levels

3- pH levels

4- Presence of organics and other chlorine-demanding substances

While there is no single universal chlorine dose, typical chlorine dosages for municipal wastewater range from 5-20 mg/L. Wastewaters with higher concentrations of pathogens or other chlorine-demanding substances may require higher dosages up to 30 mg/L or more.

Plant operators carefully monitor chlorine residual levels to ensure adequate disinfection. A free chlorine residual of 0.5-2 mg/L after the required contact time is typically maintained to demonstrate sufficient pathogen inactivation.

The presence of ammonia in the wastewater is particularly important as it reacts with free chlorine to form combined chlorine species like chloramines. While these chloramines do have some disinfecting ability, they are less effective than free chlorine. Nitrification may be required ahead of chlorination to remove ammonia if levels are too high.

Balancing pH is another key factor. The disinfection effectiveness of free chlorine is maximized in the pH range of 6-7, whereas at higher pH levels above 8, the chlorine is converted to the less effective hypochlorite ion.

Chlorine Byproducts and Dechlorination

A potential downside of chlorine disinfection is the formation of disinfection byproducts (DBPs) when the chlorine reacts with organic matter and other substances in the wastewater. DBPs like trihalomethanes and haloacetic acids have been linked to potential health risks.

To mitigate DBP formation, some plants aim to remove as much organics as possible through effective primary and secondary treatment steps ahead of chlorination. Optimizing chlorine dosages and contact times to use the minimum amount of chlorine needed can also reduce DBP formation.

In any case, residual chlorine and DBPs must be removed from the treated effluent before final discharge or reuse through a dechlorination step. Dechlorination agents like sodium bisulfite, sodium sulfite, or sulfur dioxide are dosed into the chlorinated effluent to neutralize and remove residual chlorine, converting it to innocuous chloride ions. Careful dosing of dechlorinants is required to remove chlorine residuals while not over-feeding and creating dissolved oxygen depletion in the receiving waters.

Advantages and Limitations

The main advantages of using chlorine for wastewater disinfection include:

1- Effectiveness in inactivating a wide range of bacterial, viral, and protozoan pathogens

2- Consistent reliable performance when properly implemented

3- Easily monitored and controlled dosing

4- Cost-effective chemicals and equipment required

5- Residual chlorine levels provide continued disinfection ability

However, there are some important limitations to consider:

1- Chlorine is toxic and potentially hazardous to handle and transport (chlorine gas)

2- Requires dechlorination step to remove residuals before discharge

3- Less effective in presence of ammonia, requiring nitrification

4- Sensitive to pH levels outside the ideal range

5- Potential for DBP formation which must be controlled

6- Not effective against all types of microorganisms like Cryptosporidium

Safety Precautions

Proper safety protocols and equipment are essential when working with chlorine gas or hypochlorite solutions. This includes use of appropriate personal protective equipment, self-contained breathing apparatus, leak detectors, emergency repair kits, automated safety systems, and training of all personnel.

Written safety procedures, storage requirements, and emergency response plans for a chlorine release incident are critical. Adequate ventilation systems and scrubbing equipment may be needed in areas where chlorine gas is handled.

Ongoing Monitoring and Optimization

To ensure effective disinfection while minimizing safety risks and byproduct formation, wastewater treatment facilities continuously monitor chlorine feed rates, residuals, contact times, pH, and other parameters. Process adjustments and optimizations are made as needed based on influent water quality changes.

Periodic bioassay sampling can validate the actual disinfection performance and indicate if chlorine dosages need to be increased or decreased. Adjusting chlorine dosages lower while still meeting disinfection requirements can reduce costs and DBP formation.

The Right Disinfection Solution

While advanced disinfection methods like UV radiation and ozonation have emerged, chlorine disinfection remains the most commonly used approach for wastewater treatment. When implemented properly with sufficient dosing, contact times, residual monitoring, and dechlorination, chlorine disinfection provides a classic, cost-effective, and proven solution for reducing pathogenic microorganisms to safe levels before discharging treated wastewater to surface waters or enabling water reuse applications.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.