What are the WWT Guidelines for Food processing industries in India?

The "Make in In?dia" initiative, which was launched on September 25, 2014, intends to promote India as a desirable investment destination as well as a global powerhouse for manufacturing, design, and innovation.

The Make in India project is aimed at fostering entrepreneurship in India as well as the manufacturing sector. The project also aims to create an investor-friendly climate, modern and efficient infrastructure, new industries for foreign investment, and a constructive mind set between the Government and the private sector. The Make in India project has targeted 25 sectors, including food processing.

‘Infrastructure for food safety and quality assurance, according to the Ministry of Food Processing Industries’

In the worldwide market for food items, quality and food safety have become competitive advantages. Various aspects of Total Quality Management (TQM), such as quality control, quality system, and quality assurance, should work in a horizontal way for the overall development of the country's food processing sector.

Apart from that, it is necessary to ensure that the quality of food items created as well as ingredients used for making food including pure drinking water and sold in the market,fulfil the severe requirements set by the food safety regulations in the interests of consumer safety and public health.

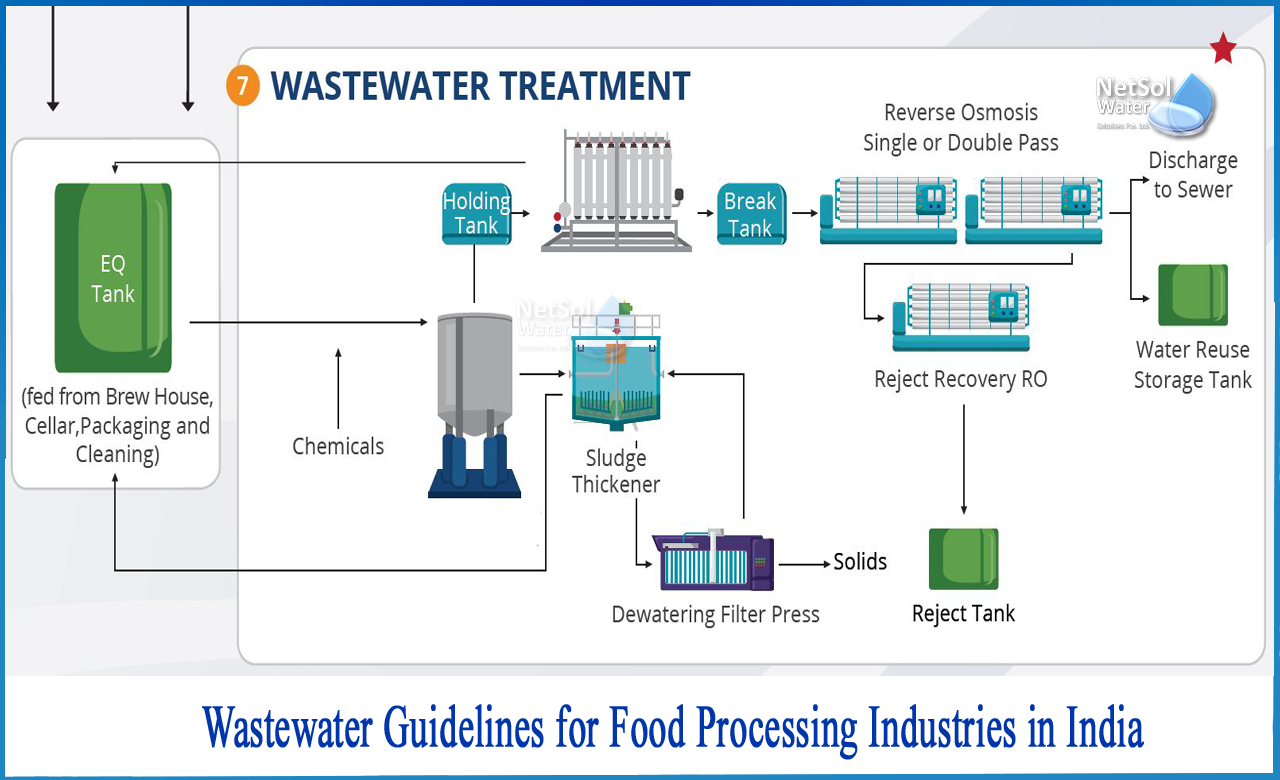

Wastewater treatment (WWT)guidelines

Following the implementation of in-plant water and waste management methods, many practises to prevent pollution are offered. Pretreatment, by-product recovery, and/or treatment are examples of these methods.

1: The options for wastewater disposal from a dairy processing factory include discharge to a municipal system or direct discharge to a stream, estuary, or the ocean.

2: Sewer usage ordinances, user charges, and pretreatment are mentioned as essential elements to consider in municipal disposal of food manufacturing wastes. Some discharge limitations to meet NPDES permits or water quality criteria were upheld by the state and municipal governments. The importance of municipal discharged is underlined because most food industry factories discharge to municipal systems.

3: There are various fundamentals for interpreting sewer use and surcharge ordinances. The connection between the federal, state, and local Governments in terms of regulating municipal discharge for pollution control is crucial. BOD-5, TSS, FOG, pH, and flow are all important parameters for dairy processors when it comes to municipal or direct discharge.

4: Spill control could be given more emphasis. It is possible to decrease and control start-up and shut-down procedures. Instead of being dumped, some raw materials can be rescued and recycled. Instead of being discharged, some by-products can be saved and sold as feed or food items.

5: Management and plant operators can benefit from education programmes that reduce product loss and water consumption.

6: Cleaning activities can be made more efficient, resulting in a reduction in the amount of water and cleaning chemicals needed. In some dairy facilities, modifications in plant design can also result in less waste.

Wastewater treatment technology for the food processing industry

Food processing wastewater treatment technologies are common among wastewater treatment solutions, and include a variety of biological and physical-chemical treatments. It is possible to use both oxidative and anaerobic methods.

Flotation, coagulation, sedimentation, filtration, adsorption, membranes, initial settling, secondary activated sludge, anaerobic digestion, and even carbon dioxide or methane recovery for further uses are just a few of them.

Anaerobic treatment of wastewater from food manufacturing

Due to the obvious opportunity to generate methane gas as a by-product, it can be used to produce heat and electrical energy to offset facility operating costs. It decreases biological activity, waste volume, and carbon footprint. Anaerobic technologies are a growing area of interest in agricultural and food processing wastewater treatment.

Conclusion

Food waste discharges contribute significantly to nutritional, carbonaceous, and nitrogenous waste outflows. Because of the pollutant loads and the variety of the diverse wastes encountered in a facility, treatment of food processing wastewater is complex and expensive.

What can Netsol Water offer?

Netsol Water is a major water and wastewater treatment company in India that manufactures WTPs, WWTPs, STPs, and ETPs, among other services. It's become our job to save the world. While conventional wastewater treatment procedures are used, anaerobic processes that produce methane gas for energy and power to offset process costs are being developed. They are environmentally friendly since they reduce waste discharges and carbon footprints in addition to lowering operational expenses.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.