Overview

Many wastewater treatment systems rely heavily on biological treatment processes. They are one of the most efficient and effective methods of removing organic matter from wastewater. There is a plethora of them that have been researched and used over the course of several decades.

The activated sludge process, on the other hand, is one of the most widely used conventional biological treatment processes (ASP). Due to the presence of human and animal organic matter in wastewater treatment plants' inlet waters, many sewage treatment plants use ASP in their secondary treatment steps.

What are the limitations of ASP?

The term "activated sludge" refers to sludge that contains live bacteria and protozoa that actively digest and degrade sewage. In that sense, it differs from sludge solids removed after settling, with the added benefit of being odorless.

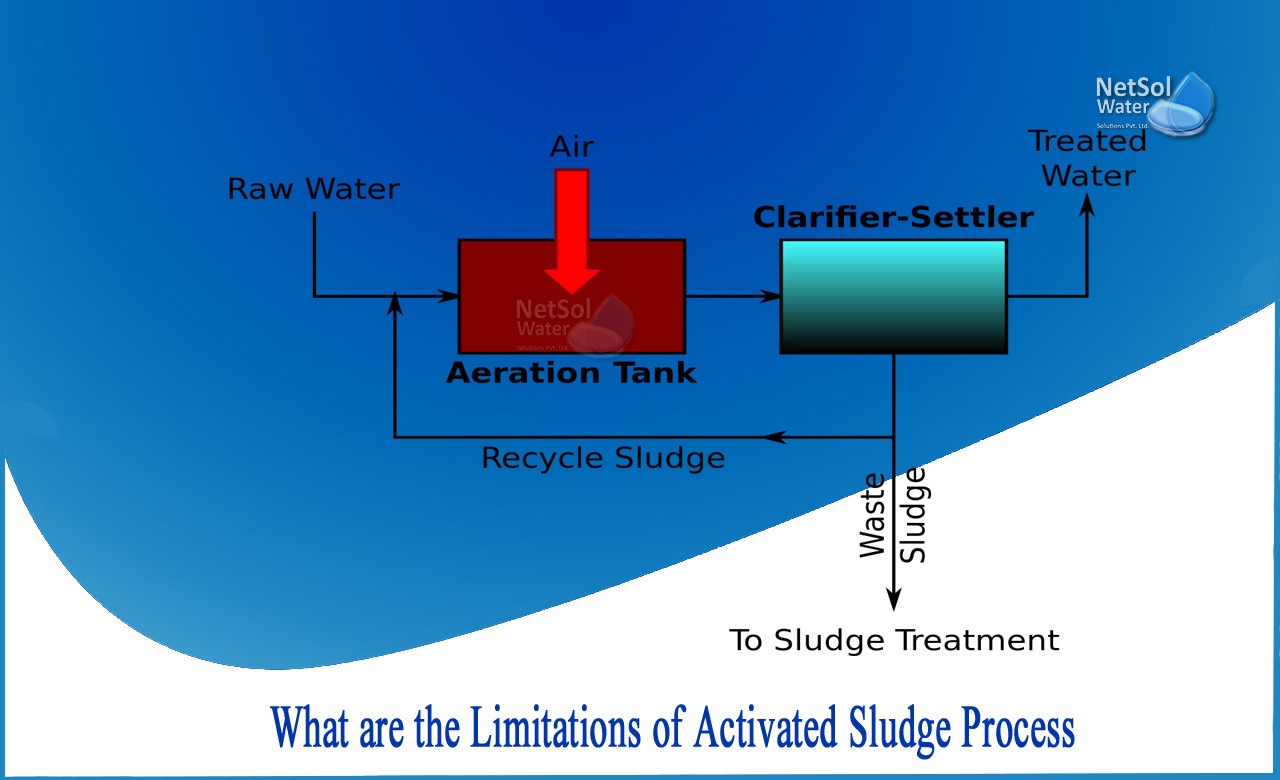

The procedure entails pumping the effluent from the primary treatment clarification step into a large tank containing the activated sludge. Aeration is applied to the mixture via submerged or surface aerators. This adds oxygen to the effluent, which bacteria can then use to break down organic waste. The resulting slurry is pumped into a clarification system or tank after a sufficient amount of hydraulic retention time to settle out the remaining solids.

The activated sludge process has some potential limitations, which are discussed below-

1. Time Required for Hydraulic Retention

Time is perhaps the most important aspect of any wastewater treatment process. Any treatment solution requires time to work, and some treatments take longer than others. One of these solutions is ASP. The hydraulic retention time of ASP can take most of a day (12-24 hrs.) or up to several days (3-5) to achieve appropriate levels of treatment results due to the sewage-to-sludge ratio and how the process occurs.

2. Sludge Retention Time/Recycling

The medium of the reaction is also affected by time. The activated sludge serves as the medium in this case. In terms of the sludge, an ASP is an open system with a different mass rate entering the system than exiting the system.

Without a recirculation system, all of the activated sludge in the tank would be pumped out over time. The goal is to reduce the amount of time the sludge spends in the system. This time is used to ensure that there is enough biomass to break down the incoming organic matter, which is why recirculation is required. As a result, while most suspended growth biological processes or fixed film processes, such as MBBR, have longer sludge retention times, ASP has shorter sludge retention times.

3. Size

Because of both of the preceding points, reactor tanks for the activated sludge process (ASP) are typically quite large in order to treat larger volumes of effluent. This necessitates large areas of land for their operation.

4. Changes in Sewage Volume or Characteristics

ASP can treat large quantities of various organic materials, but the reaction is dependent on variables that makes it prone to error in conditions other than those for which it was designed. Changes in sewage volume and sewage characteristics, in particular, can result in decreased treatment quality or treatment upsets. If a treatment plant decides to increase its treatment volume or begins treating wastewater from a new and different source, the ASP reactors must typically be completely redesigned.

5. Sludge Disposal

As would be expected from a treatment process that uses sludge to treat sewage, significant amounts of sludge must be disposed of after this process. Larger sludge volumes result in higher disposal costs.

6. Supervision/Operation

Because biology is a complex subject, it stands to reason that a biological water treatment process would be complex in some ways. On a broad scale, the overall process appears to be straightforward. However, the design and operation of an activated sludge reactor typically necessitates the involvement of experts in biological system design. A system like this necessitates more skilled supervision than simply keeping an eye out for mechanical failures and monitoring pH. To prevent system disruptions, highly skilled operators and supervisors must check the viability and efficiency of the bacteria and protozoa in the sludge.

7. Problems with Sludge Settlement

Some of the most serious problems with the activated sludge process are revealed in how everything settles out during the secondary clarification process. Sometimes the solids don't compact well at the bottom, and the sludge contains a lot of water.

When the supernatant (floating material) has a higher turbidity than desired, the end effluent water quality suffers. Other factors can contribute to lower concentrations of return activated sludge.

What can Netsol Water offer?

Netsol Water offers a comprehensive range of water and wastewater treatment technologies and services to meet the demands of a variety of industries, and our skilled staff can make suggestions on the best solution. This might be as simple as optimizing current equipment and methods to achieve the desired performance or including a new phase into the treatment process.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.