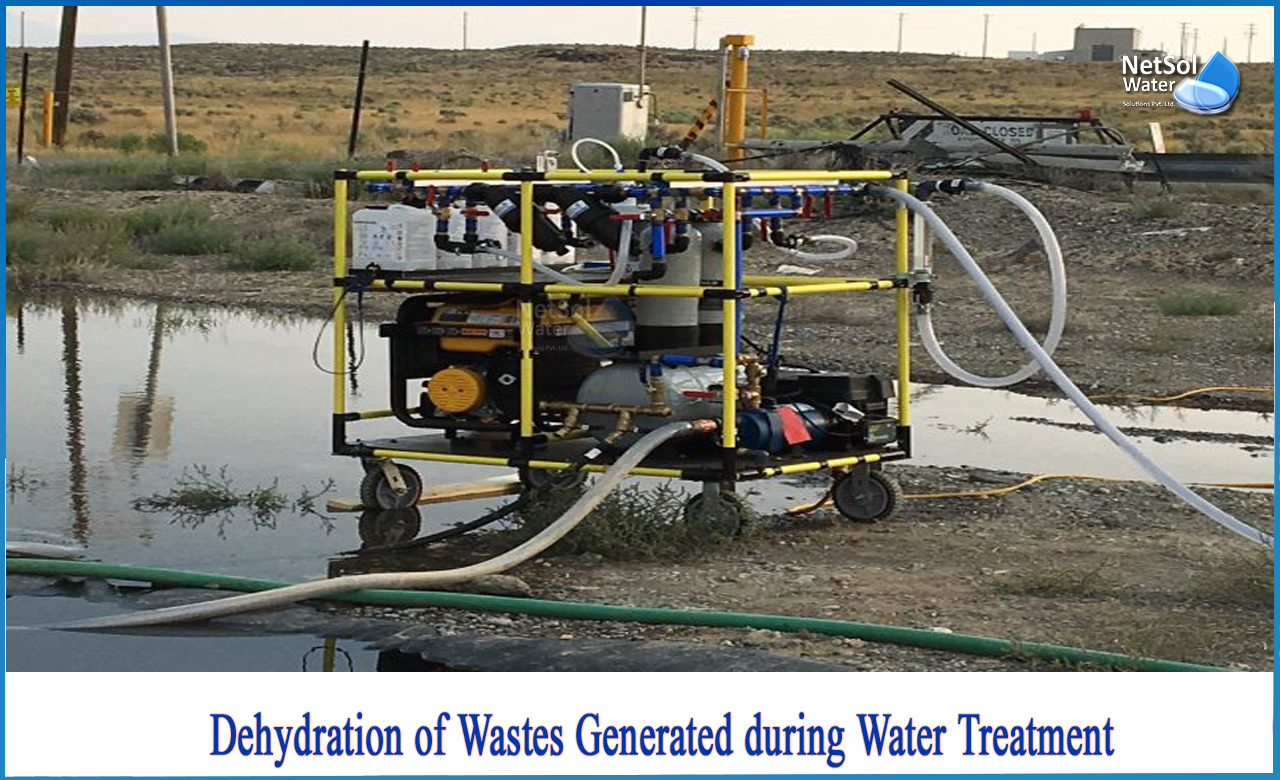

How to Dehydration of wastes generated during water treatment?

For sludge with varied water contents, the dehydration treatment procedure normally concentrates the sludge first, adds a conditioning agent, and then dehydrates the sludge.

The sludge is first transferred to a gravity concentration tank, where it is concentrated; the concentrated sludge is then mixed with a conditioning agent and delivered to a dehydrator, where it is dehydrated. When the dehydrated sludge meets the requirements for final disposal, it can be disposed of in an appropriate manner. If not, the dehydrated sludge can be dried further until it meets the requirements for final disposal, at which point it is disposed of appropriately.

Dehydration extraction treatment technology

Water-treatment systems generate a lot of solid waste that contains a lot of water. It is vital to eliminate this water, in part or altogether, in order to save transportation and administration costs.

Factors determining Sludge dehydrating process

The qualities of the sludge produced, as well as external factors, will decide the most convenient dehydration technique in each instance, i.e., workforce availability, energy prices, space available, etc. If a high level of dryness is necessary, a heat treatment must also be used.

Methods of Sludge Dehydration

Some of the most effective waste dehydration methods are:

1. Band filters

2. Filter presses

3. Vacuum filters

4. Centrifugation

5. Thermodynamic drying

Process of sludge dehydration

Slurrying waste (wet-waste) in a hydrocarbon solvent recovers indigenous oil from contaminated solid particles and concentrates it in the solvent phase, according to the dehydration/solvent extraction process.

1: During the treatment, water is evaporated and condensed as a distinct product, resulting in dehydration.

2: Depending on the degree of extraction required, dry solids are re-slurred in fresh solvent one or more times.

3: The solvent is removed from the extracted solids by centrifugation, and the leftover solvent in the centrifuge cake is evaporated off the final product solids stream in a de-solventizer.

4: Distillation separates the indigenous oil from the solvent, with the recovered solvent being recycled back into the process.

Enhancing the effectiveness of sludge

The effectiveness of the dehydration process improves significantly if sludges are chemically conditioned beforehand, regardless of the dehydration procedure. Iron chloride, iron or aluminium sulphate, and calcium oxide are the most commonly utilized compounds. Because they are easy to dose, cationic polyelectrolytes have also been employed with great success.

The most effective product and dose will be determined by the sludge's characteristics, which is why laboratory testing are required in each situation. Because it takes a lot of energy to evaporate water, thermal drying can only be utilized when there is leftover energy from another process.

Conclusion

The drainage, dehydration, and sludge drying procedures help to reduce the volume of waste generated, lowering the costs of destination and transportation of such materials and ensuring the project's long-term viability. Netsol Water is the solution to all your water and wastewater treatment needs. Our goal is to make the world's water, wastewater and waste management systems affordable, sustainable, and energy-efficient in order to address the problems of population growth, industrial expansion, and climate change.

For further assistance or product-purchase related query,

Call on +91-9650608473;

Or write us at enquiry@netsolwater.com