Why are commercial RO filters used in steel and iron industry?

Commercial RO (Reverse Osmosis) filters are used in the steel and iron industry primarily to treat wastewater and recycle it for various industrial processes. The steel and iron industries use a large amount of water in their production processes, and much of this water is contaminated with impurities and chemicals. The use of commercial RO filters helps to reduce the cost of water consumption, protect the environment by reducing wastewater discharge, and comply with regulatory requirements.

Here are some specific reasons why commercial RO filters are used in the steel and iron industry:

1. Waste?water Treatment: Commercial RO filters are used to treat the wastewater generated from various processes in the steel and iron industries, such as cooling towers, descaling, and rinsing. These filters remove impurities and contaminants from the wastewater, making it safe for reuse in various industrial processes.

2. Co?st Reduction: The use of commercial RO filters can help reduce the cost of water consumption by allowing the steel and iron industries to recycle wastewater for various industrial processes. This reduces the need for freshwater, which can be expensive, and helps to reduce overall production costs.

3. En?vironmental Protection: The use of commercial RO filters helps to reduce the discharge of wastewater into the environment, which can be harmful to the ecosystem. By recycling wastewater, the steel and iron industries can reduce their environmental impact and contribute to a more sustainable future.

4. Re?gulatory Compliance: The use of commercial RO filters helps the steel and iron industries to comply with regulatory requirements related to wastewater discharge. By treating the wastewater before discharge, the industries can meet the required water quality standards and avoid penalties for non-compliance.

Working of commercial RO filter systems for steel and iron industries:

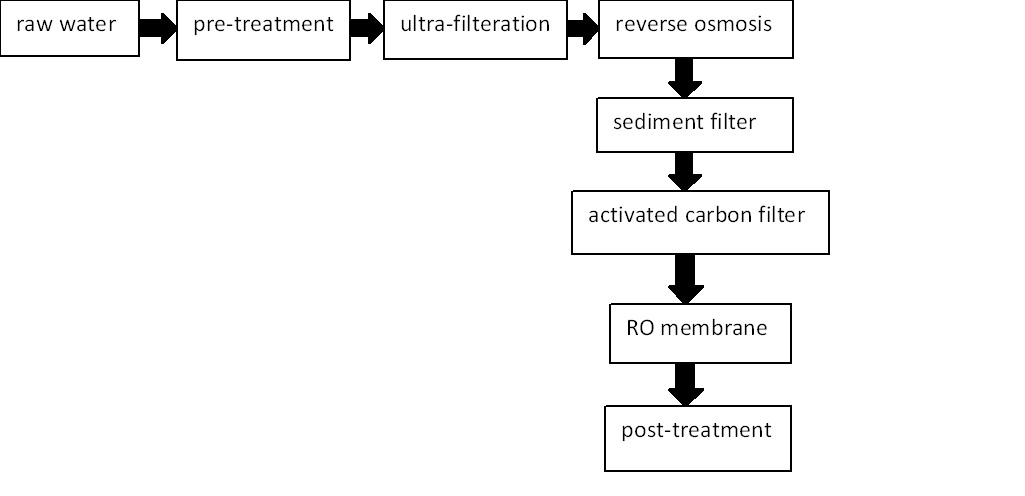

Commercial RO (Reverse Osmosis) filter systems are widely used in the steel and iron industries to treat wastewater and recycle it for various industrial processes. These systems are designed to remove impurities and contaminants from the wastewater, making it safe for reuse. Here is a flowchart that outlines the working of commercial RO filter systems in steel and iron industries:

1. Wastewater Source: The first step is to identify the wastewater source, which can be from various processes in the steel and iron industries, such as cooling towers, descaling, and rinsing.

2. Pre-Treatment: The wastewater undergoes pre-treatment to remove large particles, debris, and organic matter. This can be achieved through various methods such as sedimentation, filtration, and coagulation-flocculation.

3. Ultrafiltration: The pre-treated wastewater then undergoes ultrafiltration, which is a membrane-based separation process that removes suspended solids, colloidal particles, and microorganisms from the water.

4. Reverse Osmosis: The ultrafiltered water then enters the commercial RO filter system. The RO filter system consists of several components, including the sediment filter, activated carbon filter, RO membrane, pressure vessel, pumps, and control panel.

5. Sediment Filter: The sediment filter removes any remaining sediment, rust, or sand particles from the water.

6. Activated Carbon Filter: The activated carbon filter removes chlorine, odors, and organic matter from the water, improving its taste and odor.

7. Reverse Osmosis: The water is forced through the RO membrane, which acts as a barrier, allowing only pure water molecules to pass through. The impurities and contaminants are left behind and are discharged as reject water.

8. Post-Treatment: The purified water then undergoes post-treatment, which involves the addition of minerals to improve the quality of the water and balance its pH.

9. Storage: The purified water is then stored in a tank, which is typically made of stainless steel, to maintain its purity and prevent contamination.

10. Distribution: The purified water is distributed to various points of use within the steel and iron industries for various industrial processes, such as cooling, rinsing, and descaling.

11. Quality Control: The purified water is subject to regular quality control testing, which involves various parameters such as pH, total dissolved solids, and bacterial count, to ensure that it meets the required quality standards.

12. Maintenance: Regular maintenance of the RO filter system is essential to ensure that it operates at peak efficiency and maintains the required quality standards.

Conclusion:

To treat and recycle wastewater for different industrial processes, commercial RO filter systems are essential in the steel and iron industries. The manufacture of steel and iron requires a significant amount of water, much of which is tainted with pollutants and chemicals. Commercial RO filters are used to comply with regulations, save money on water consumption, and safeguard the environment by lowering wastewater output. The above flowchart outlines the various steps involved in the working of commercial RO filter systems in steel and iron industries.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us now your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-965-060-8473

Or write us at enquiry@netsolwater.com