An important share of the world's water consumption is accounted for by industrial water use. Reusing industrial water has become more popular as a sustainable way to lessen the strain on freshwater resources, cut expenses, and protect the environment as water shortage becomes an increasingly urgent issue. We shall discuss the idea of industrial water reuse, its advantages, and its numerous uses in a variety of industries in this blog.

What is Industrial Water Reuse?

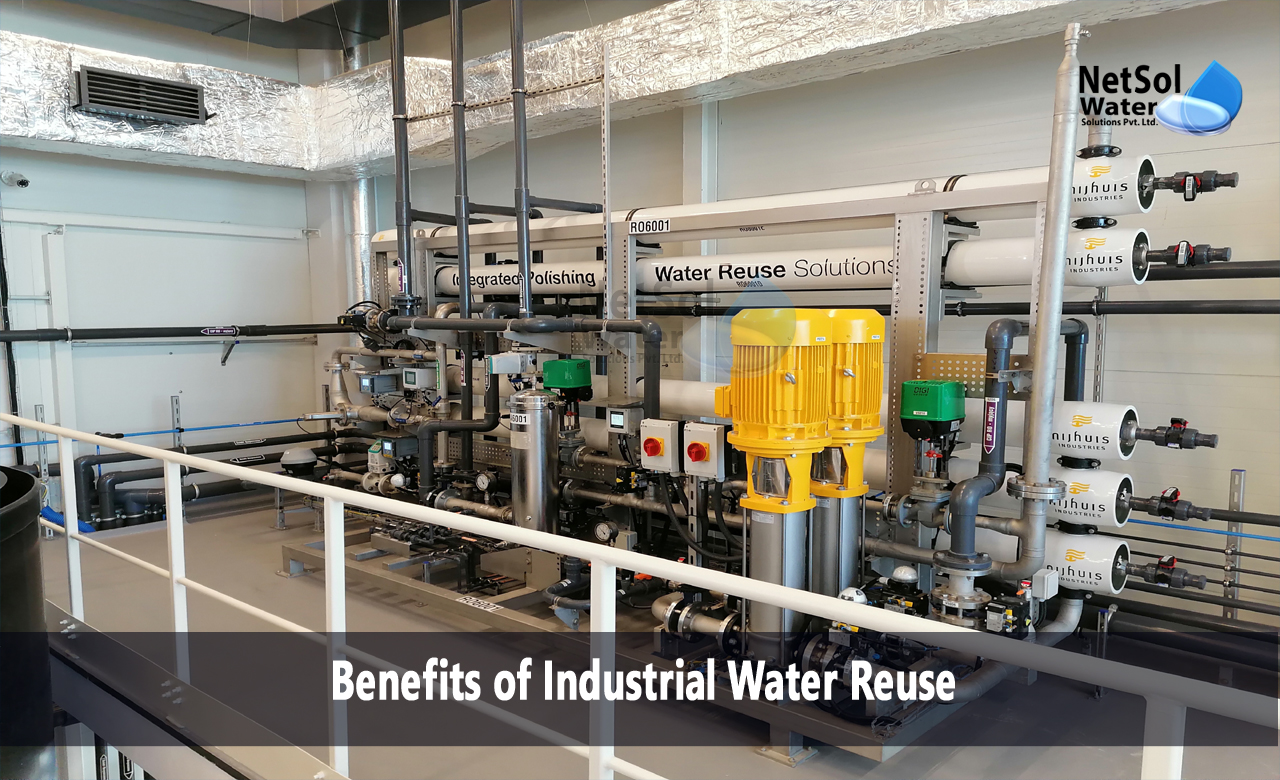

Reusing and treating water for use in industrial operations is known as industrial water reuse, sometimes known as water recycling or water reclamation. Industrial establishments capture, treat, and reuse their wastewater, which lessens their dependency on outside water supplies, as opposed to only using freshwater sources.

What are the benefits of Industrial Water Reuse?

· Preservation of Freshwater Resources: The preservation of freshwater resources is the most obvious advantage of industrial water reuse. Industries may help ensure sustainable water management by reducing their dependency on scarce and frequently overstretched local water sources by recycling and reusing water.

· Cost Savings: Industries can save a lot of money by implementing water reuse technologies. Generally speaking, treating and reusing wastewater is less expensive than obtaining freshwater and discarding of wastewater. It also lowers the costs related to adhering to strict wastewater discharge guidelines.

· Environmental Benefits: Reusing industrial water reduces the harm that effluent discharges cause to the environment. Water recycling helps to preserve local ecosystems and aquatic ecosystems by reducing the amount of pollutants and contaminants that industrial operations release into natural water bodies.

· Enhanced Corporate Responsibility: A company's reputation and image can be improved by showcasing a dedication to water conservation and environmental sustainability. This might be crucial for businesses looking to satisfy consumer demands for eco-friendly products and sustainability targets.

Applications of Industrial Water Reuse

· Production: Water is needed in large quantities for a number of production processes, including those in the textile and automobile sectors. These industries can reduce their freshwater use and wastewater output by putting in place water reuse systems.

· Food & Beverage: This industry frequently produces wastewater that can be safely repurposed for non-potable uses such as irrigation, cooling, and cleaning if it is properly treated.

· Petrochemical and refining: By recycling cooling water and process water, these industries can lessen their reliance on freshwater resources and adhere to stringent environmental standards.

· Agriculture: Reclaimed water can be utilised for irrigation in agricultural applications. This lessens nutrient discharge into surrounding water bodies and preserves freshwater supplies.

· Mining: The processing of minerals in mining activities requires a significant amount of water. Mining businesses can lessen their environmental effect and alleviate water scarcity in areas that are water-stressed by recycling water.

Challenges and Considerations

Industrial water reuse has many benefits, but there are drawbacks as well.

· Water Quality and Treatment: Wastewater has a wide range of quality and requires complicated treatment. Successful reuse requires efficient treatment and regular monitoring of the quality of the water.

· Regulatory Compliance: To make sure that recovered water satisfies the essential quality standards, industries must negotiate a challenging regulatory environment. Adherence to municipal, state, and federal laws is essential.

· Initial Investment: There must be a capital outlay for infrastructure and technology in order to implement a water reuse system. Some industries may find this initial expense prohibitive, despite the possibility of long-term savings.

· Public Perception: It can be difficult for the public to accept industrial water reuse since some localities may have doubts about the dependability and safety of recovered water. To solve these issues, effective communication and transparency are crucial.

Conclusion:

Reusing industrial water is a cost-effective and environmentally friendly way for businesses to lessen their dependency on freshwater resources, cut expenses, and protect the environment. Industry use of water recycling techniques is essential for conserving water resources and safeguarding the environment as water shortage becomes a global concern.

The industrial sector may ensure sustainable and responsible water management by utilising effective treatment technology, following regulations, and addressing public concerns via education and communication. Industrial water reuse can be a major contributor to this effort. Industrial water reuse is expected to become a mainstream practise for responsible resource management as firms continue to adjust to shifting economic and environmental environments.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.