What is activated sludge process explain in details?

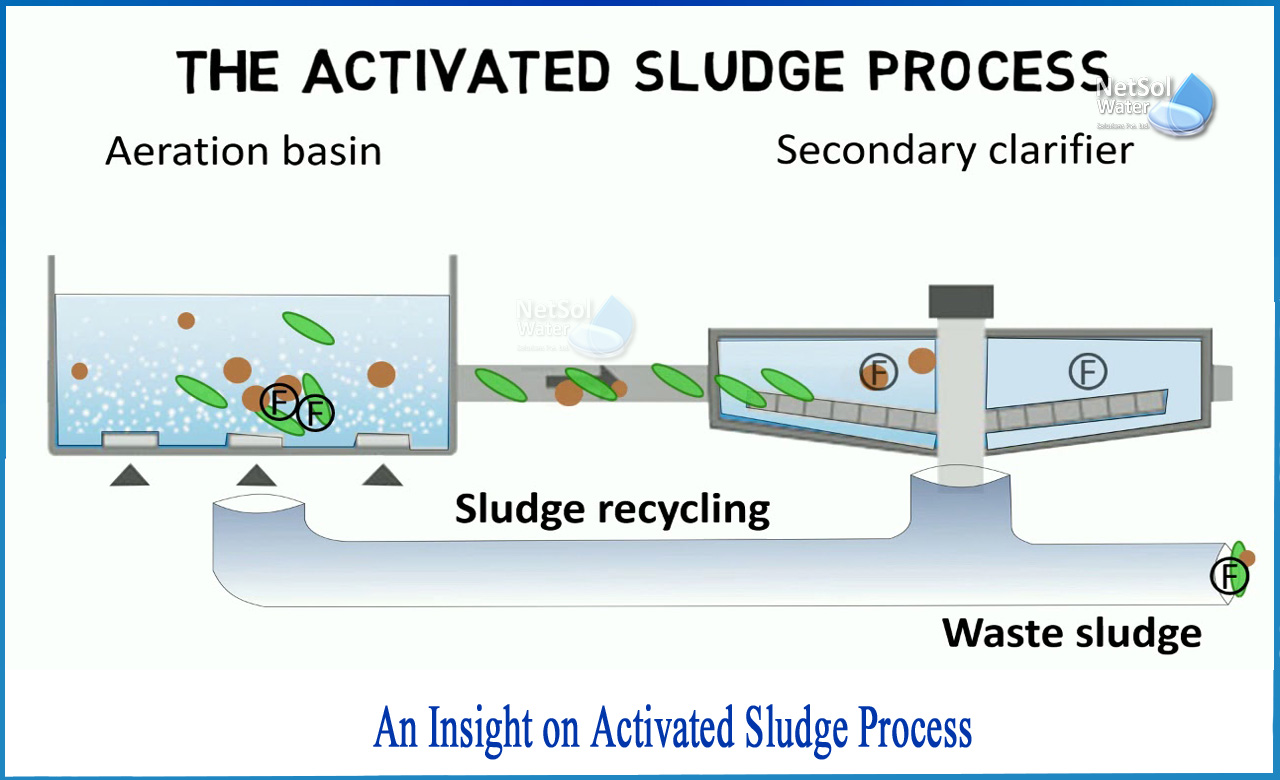

Developed in England in 1914, the Activated Sludge Process (ASP) is the most commonly used technology for biological wastewater treatment under aerobic conditions. It is a suspended growth process in which the organisms are suspended in the wastewater The activated sludge process consists of an aeration tank where organic matter is stabilized which relies on the cultivation of a population of millions of bacteria and a secondary sedimentation tank where the biological cell mass suspended in the wastewater of aeration tank is separated out. The sludge after getting removed from aeration tank is recycled.

At the bottom of the tank, diffusers are provided and at the surface of the water, mechanically aerated, either floating or fixed, supports are provided. The raw wastewater after settlement and a portion of sludge enters from the head of the tank in spiral flow pattern in case of diffused air aerators, or gets uniformly mixed in case of completely mixed reactors. In the settling tank, the effluent gets settled and the sludge is returned.

What is the purpose of ASP?

In a sewage treatment plant, the activated sludge process can be used for one or several of the following purposes:

i) Oxidation of carbonaceous matter: Biological matter.

ii) Oxidation of nitrogenous matter: Mainly ammonium and nitrogen in biological materials.

iii) Removing of phosphate.

iv) Driving off entrapped gases carbon dioxide, ammonia, nitrogen, etc.

v) Generation of a biological floc that is easy to settle.

vi) Generation of a liquor flow in dissolved or suspended material.

Sludge return rate and quantity of return sludge:

1: Sludge return rate or return activated sludge (RAS) rateis essential in maintaining an adequate MLSS concentration in the aeration tank. For large plants, sludge return rates are 50 to 100 percent of the wastewater flow and up to 150 percent of the wastewater flow rate for small plants. The return-sludge flow rate should be maintained to keep the sludge blanket as low as possible.Optimum rate of returning activated sludge varies with each installation and with different load factors.

2: Quantity of return sludge: For conventional ASPs, solid concentration of about 1500 to 3000 mg/L (MLVSS-80% of MLSS) is usually maintained and 3000 to 6000 mg/L for completely mixed ASPs is maintained. To maintain this concentration, the quantity of return sludge is determined accordingly.

What is Sludge bulking?

In sewage treatment, one process used is the activated sludge process in which air is passed through a mixture of sewage and old sludge to allow the micro-organisms to break down the organic components of the sewage. Sludge is continuously withdrawn as new sewage enters the tank and this sludge must then be settled so that the supernatant (the remaining liquid) can be separated to pass on to further stages of treatment.

The sludge which fa?ils to settle out in the sedimentation tanks is called as “Bulking of Sludge”.

The main cause of sludge bulking is the growth of filamentous bacteria which doesnot allow desirable compaction. The filamentous bacteria can make the flocs more open, and bacteria grow to a large extent outside the biological flocs. Another reason of sludge bulking is process failure due to uncontrollable production of highly hydrated biomass with the effluent. To avoid sludge bulking, some of the flow that enters the reactor can be bypassed, restoration of proper air supply, recycle ratio can be increased, or by increasing the temperature of wastewater, or by adding lime or soda to avoid growth of filamentous bacteria.

Activated sludge process variables-

The variables of activated sludge process are:

a) Mixing regime

b) Loading rate, and

c) The flow scheme

A: Mixing Condition

Two types of mixing regimes are generally of major interest in activated sludge process: plug flow type and completely mixed type.

In the plug flow type, the regime is characterized by orderly flow of mixed liquor through the aeration tank with no element of mixed liquor overtaking or mixing with any other element. There may be lateral mixing of mixed liquor but no mixing along the path of flow. The F/M and oxygen demand will be highest at inlet end and thereafter decreases progressively.

In complete mixing regime, the contents of aeration tank are uniform throughout. At steady state, the effluent from the aeration tank has the same composition as the contents of aeration tank. The F/M and oxygen demand remains uniform throughout the aeration tank.

The type of mixing regime is very important as it affects: oxygen transfer requirements in the aeration tank, susceptibility of biomass to shock loads and the kinetics governing the treatment process.

B: Flow Scheme

Sewage may be added at a single point at the inlet end of the aeration tank or at various points along the tank. The sludge return is carried out from the underflow of the sedimentation tank to the aeration tank or through a sludge reaeration tank. The sludge wastage is done from return sludge line or from aeration tank itself. Sludge wasting from the aeration tank will have better control over the process, however in this case,higher sludge waste volume needs to be handled due to lower concentration. Aeration remains uniformor it may be varied.

The flow scheme involves:

i) The pattern of sewage addition;

ii) The pattern of sludge return to the aeration tank; and

iii) The pattern of aeration.

How can Netsol Water help you?

Netsol Water is one of the leading water and wastewater treatment company in India with services in the field of WTP manufacturing, WWTP manufacturing, STP manufacturing, among other services. The company designs and manufactures all in one systems that are ideal for treating wastewater and the sludge generated and not only turns your wastewater into usable water but also acts as a savior of Mother Earth and its precious resource “water”.