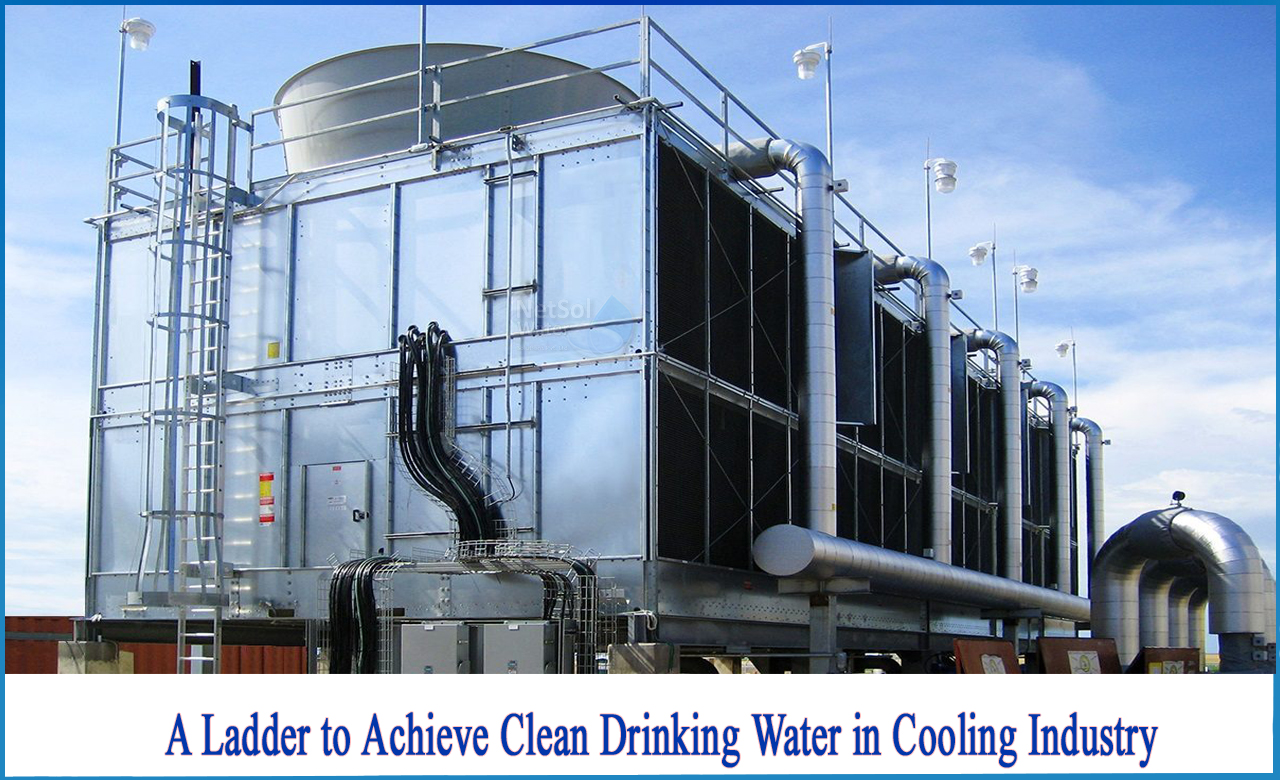

How to achieve clean drinking water in cooling industry?

The water-cooling market is growing, and industry managers are under pressure to improve efficiency and reduce costs. Clean water is an important part of the process. Improved technology is constantly evolving to ensure optimal system performance. Netsol is a world leader in water treatment. The team is a water filtration expert.

What are the trends driving the demand for improved, high-efficiency submicron filtration in the water-cooling market today?

Many factors demand high efficiency filtration of HVAC systems and cooling towers:

-Water Reuse and Condenser and Makeup Water Green Initiative Data centre and semiconductor requirements for high quality water requirements for improving the efficiency of the cooling system;

-Need to reduce maintenance and operating costs;

-The need to develop a risk assessment program to reduce health risks.

Why is high efficiency media filtration important for HVAC systems and cooling towers?

Total suspended solids (TSS) with a size of less than 5.0 micro-meters play an important role in biofilm formation. The formation of biofilms increases the energy costs of operating refrigerators and heat exchangers. Health accidents such as Legionella related to cooling towers are also increasing.

Keeping the water in the condenser clean is important for creating a safer environment while strengthening the biocidal chemical treatment program. The results of the laser particle distribution analysis show that 85% of the particles in the cooling tower water sample are less than 5 micrometres.

What are the biggest concerns about condenser and make-up water reuse in terms of water reuse and green initiatives?

Water reuse is a growing business market. Municipal water authorities have more stringent restrictions on the use of drinking water for industrial/commercial cooling water. The basic concern about water reuse is the cost of capital and operating costs to provide a trouble-free cooling water system. Depending on the degree of treatment, the recycled water may contain a large amount of fine suspended or dissolved solids. This can lead to clogging, dirt, or biofouling problems with system components.

These issues lead to unplanned shutdowns, additional maintenance costs, and heat exchanger inefficiencies. As mentioned above, health effects from bacterial contamination can also occur. The water source used for freshwater in the cooling tower presents a variety of challenges and solutions, whether drinking water, wells, surface, or tertiary treated wastewater.

How data centres and semiconductor systems are usually cooled, and what are the cooling problems?

Data centres come in different designs and sizes with different types of cooling configurations. The use of devices with low water requirements, such as air-cooled economizers and evaporative coolers, has been promoted. This device reduces the number of open cooling circuits while increasing the number of closed cooling water circuits.

Semiconductor manufacturers, on the other hand, need as pure water as possible for final production. The treatment/filtration of water in the bath tank is important in all bath tank phases, not only for the process, but also for the heat exchange system that may be installed with this water. Customers tend to use both UV disinfection technology and high efficiency filtration to improve the water quality of cooling towers.

How can high efficiency submicron filtration improve cooling efficiency to meet today's needs?

Providing the cleanest filtered water can reduce or maintain the efficiency of the entire system. Removing fine solids can help save energy, improve, and save chemicals, improve equipment lifecycles, and reduce labour and downtime by optimizing water quality and efficiency.

How much highly efficient submicron filtration help reduce the operating and maintenance costs of cooling systems?

Providing submicron quality water reduces the risk of biofilm contamination in heat exchangers, cooler/condenser tubes, and cooling tower fillings. Reducing these risks reduces energy costs and allows heat exchangers to operate at the intended efficiency. Cleaner water leads to more effective chemical treatment and less consumption. Cleaner systems have lower manual cleaning costs.

Highly efficient filtration helps extend the life of the entire system, including the plumbing (reduces the risk of corrosion). When used in pre-treatment, it protects downstream systems, including manufacturing processes and final products. Ultimately, the entire system will function as intended and achieve a higher level of efficiency.

Consult Netsol Water for more information!