How is silt density index essential in sea water RO application?

The SDI (Silt Density Index) is a very important parameter utilized in seawater reverse osmosis (SWRO) packages to objectively calculate the degree of compatibility of the incoming water with the reverse osmosis membranes. It is the calculation of silt density in any water. Since sea water contains high amount of slats, it is even more important to conduct SDI, in order to save membrane from failing and fouling.

Membrane fouling is the main cause of failure of RO systems. So, membrane fouling control dominates RO system design and operation.Membranes are fouled by four types of impurities in water: scale, silt, bacteria and organic fouling.

Fouling control involves pre-treatment of the feed water to minimize fouling as well as regular cleaning to handle fouling that still occurs. Fouling by particulates (silt), bacteria and organics generally affects the first membranes in the treatment plant the most. Scaling is worse with more concentrated feed solutions, therefore the last modules in the treatment.

Let’slook at method of SDI calculations:

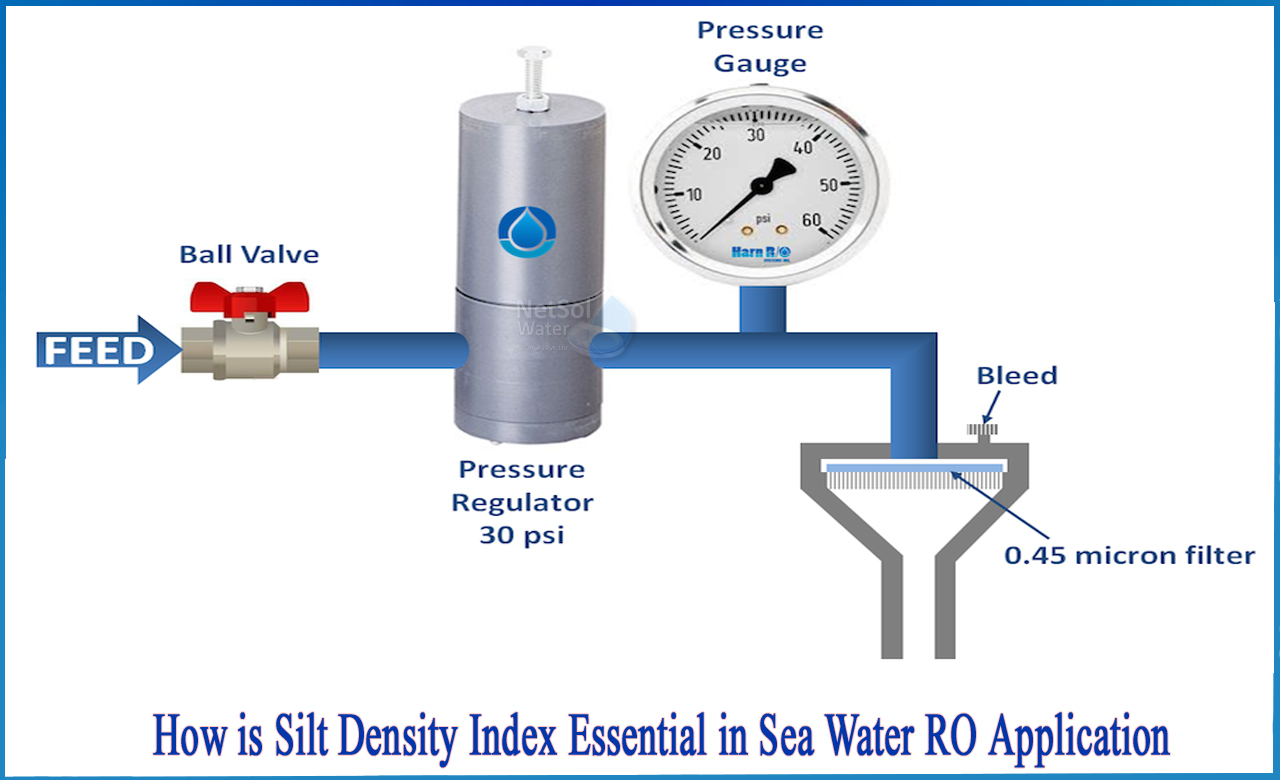

It consists of passing feed water through a 0.45-µm membrane ?lter at a regular interval of 5, 10 and 15 minutesat a gauge strain of 207 kPa (30 psi). The measurement of plugging rate shows if the water is okay to be used as feed water for RO or not. SDI levels are aimed below 3 for sea water RO systems.

Use of Silt Density Index:

The SDI can show the amount of particulate matter that is permissible for your feed water. The SDI is beneficial in figuring out the effectiveness of numerous processes, along with ?ltration or clari?cation, used to get rid of particulate matter. The SDI may also range as a characteristic of water temperature; as a result, values acquired at special temperatures might not always be comparable. The required degree of SDI will show the manufacturers which grade of membrane filters should be manufactured. Thus, it’s important to know the SDI value.

Recent trends have additionally tested that the system of degree, along with the filtration support, also can contribute to a few distinctionsin the very last SDI value. Nevertheless, the degree of SDI is likewise beneficial from a running factor of view. Water specialists make use of measures of SDI daily to make certain the pre-treatment filtration is producing clean- compatible water to the reverse osmosis system

Plugging Time Comparison - Multimedia vs Crossflow Microsand Filter Technology ?

Various plugging observations has been crafted from two different styles of pre-treatment systems (conventional multimedia and crossflowMicrosand filtration systems) to comprehend the connection among high level of SDI and plugging time.

Silt Density Index Objective for RO Membranes

The goal of SDI test is to get feed water for RO having SDI level lower than 3. Traditional granular filtration and multimedia filters now no longer constantly meet this goal. Often, the RO feed waterhas terrible feed water coming from their pre-treatment system, yielding an SDI higher than 5. Unfortunately, such high level of SDI can increase the ability for membrane fouling. Therefore, bad pre-treatment in SWRO packages can bring about routine cleanings of the RO membranes, subsequently leading to early membrane replacement.

Contact Netsol Water for more information!

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.