Anaerobic digestion has been shown to be an efficient method of treating all types of sewage. In the absence of oxygen, microorganisms degrade organic waste and capture energy in the form of biogas. Aside from the potential for energy generation, anaerobic wastewater treatment systems have low energy requirements, and sludge management costs.

Anaerobic digestion can reduce power consumption by 70% to 90% and produce 90% less bio solids, than aerobic treatment. Anaerobic reactors range in rate from high to low rate.

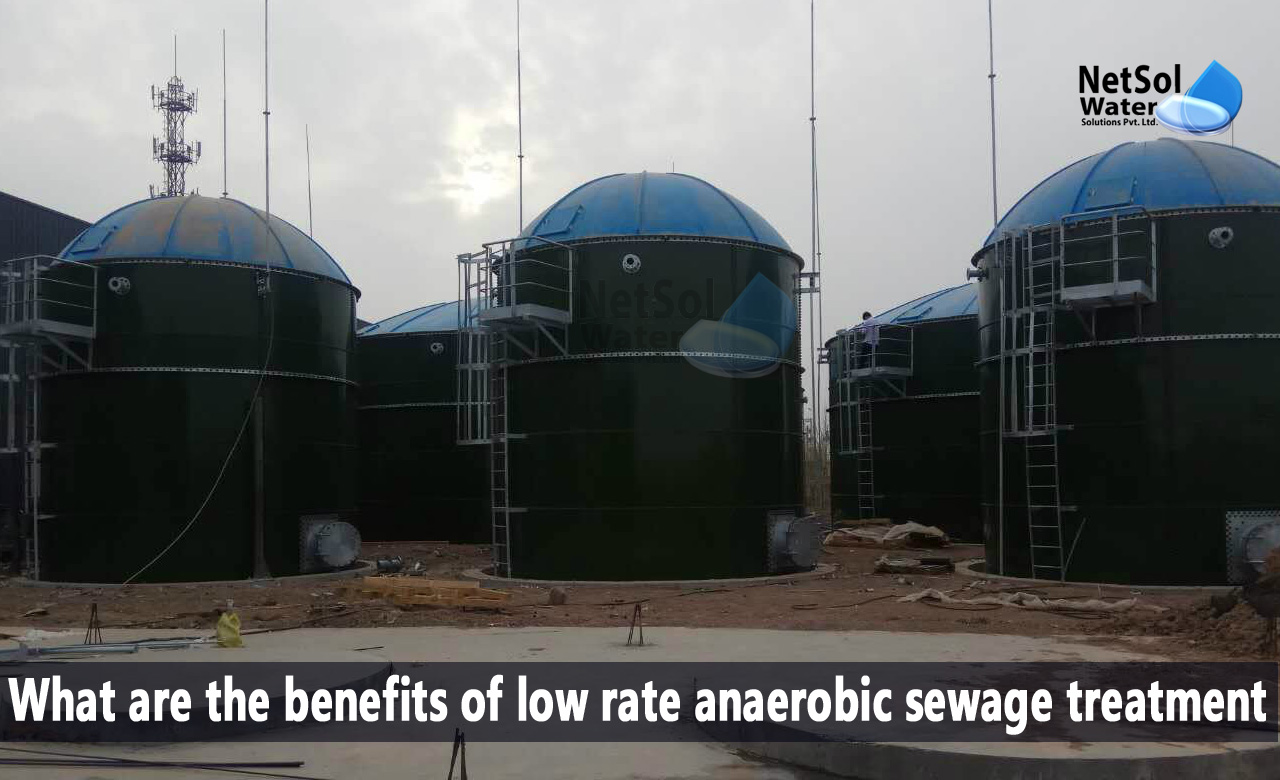

Treatment of sewage through low rate anaerobic sewage treatment

The anaerobic reactor would pre-treat up to 2 million gallons of combined wastewater per day, significantly reducing organic load on the downstream system.

Several combined wastewater streams are pre-treated by the low-rate reactor, including powder line wastewater, a portion of cheese line wastewater, and salty whey wastewater in dairies. The streams enter the reactor through a network of pipes beneath the sludge bed.

After that, wastewater flows upward through the sludge bed, where microorganisms digest the feed, and remove biochemical oxygen demand, chemical oxygen demand, and total suspended solids, while converting the majority of the organic load into energy-rich biogas.

Applications of low rate anaerobic sewage treatment systems

1. Distilleries

2. Breweries

3. Dairy Industries

4. Food Industries

5. Pharmaceuticals

6. Paper & Pulp

7. Chemical Industries

Benefits of low rate anaerobic sewage treatment plants

· These digesters have hydraulic retention time of 15-45 days. It improves process stability, while also producing biogas.

· Depending on the nature of the wastewater, BOD reductions of 80%-95% and COD reductions of 60%-80% are possible. The digesters can be built above or below the ground,either in rectangular or circular shapes.

· Bacteria decompose organic pollutants (BOD, COD, etc.) to carbon dioxide, methane, and water in the absence of oxygen, i.e. in an anaerobic environment.

· A series of biomethanation reactions produce the biogas. The large amounts of biogas produced have been used to replace fuel in boilers, and to generate electricity in generators, providing our clients with quick returns.

· This anaerobic system provides significant reductions in organic load, resulting in less loading and power consumption in the downstream treatment process.

Use of low rate anaerobic sewage treatment plants in dairy industry

The reactor's operating temperature is kept between 79o and 86oF, with an average temperature of around 82°F (28°C). This is lower than the typical operating temperature for anaerobic digesters treating dairy processing wastewater, resulting in energy savings for temperature maintenance.

Conclusion

Anaerobic digestion is becoming a more popular wastewater treatment technology. We specialize in the turnkey design and construction of anaerobic wastewater treatment plants.

The system uses less energy and chemicals, generates fewer biosolids, and provides greater process stability, higher-quality effluent, and, ultimately, a higher economic return.

Manufacturers of various types of sewage treatment plants

Sewage Treatment plants from Netsol Water have been able to serve communities, for many years thanks to our comprehensive assistance from the pre-application stage, to the design and construction phases.

If you have any questions about low-rate anaerobic sewage treatment plants, or if you would like to discuss your specific needs, please contact the Netsol Water team right away. Our team is an expert in sewage treatment and can help you tailor a solution, to your specific requirements.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.