Wet Scrubbers are useful for treating and eliminating chemical residues from exhaust fumes.

Scrubbers inject cleaning chemicals into the scrubber while, the counter currently passing exhaust vapor through it. The needed contact time between the vapor and the cleaning solution is determined by the chemical, the concentration of the chemical in the vapor, and the required removal efficiency.

Typically, acidic solutions interact with basic pollutants while basic solutions interact with acidic contaminants. Salts are formed and remain in the liquid stream. The contact time is controlled to allow enough time for the chemicals to react, with the cleaning liquid and drop out of the vapor. These scrubbers produce clean exhaust for release into the atmosphere, with 99% destruction rates.

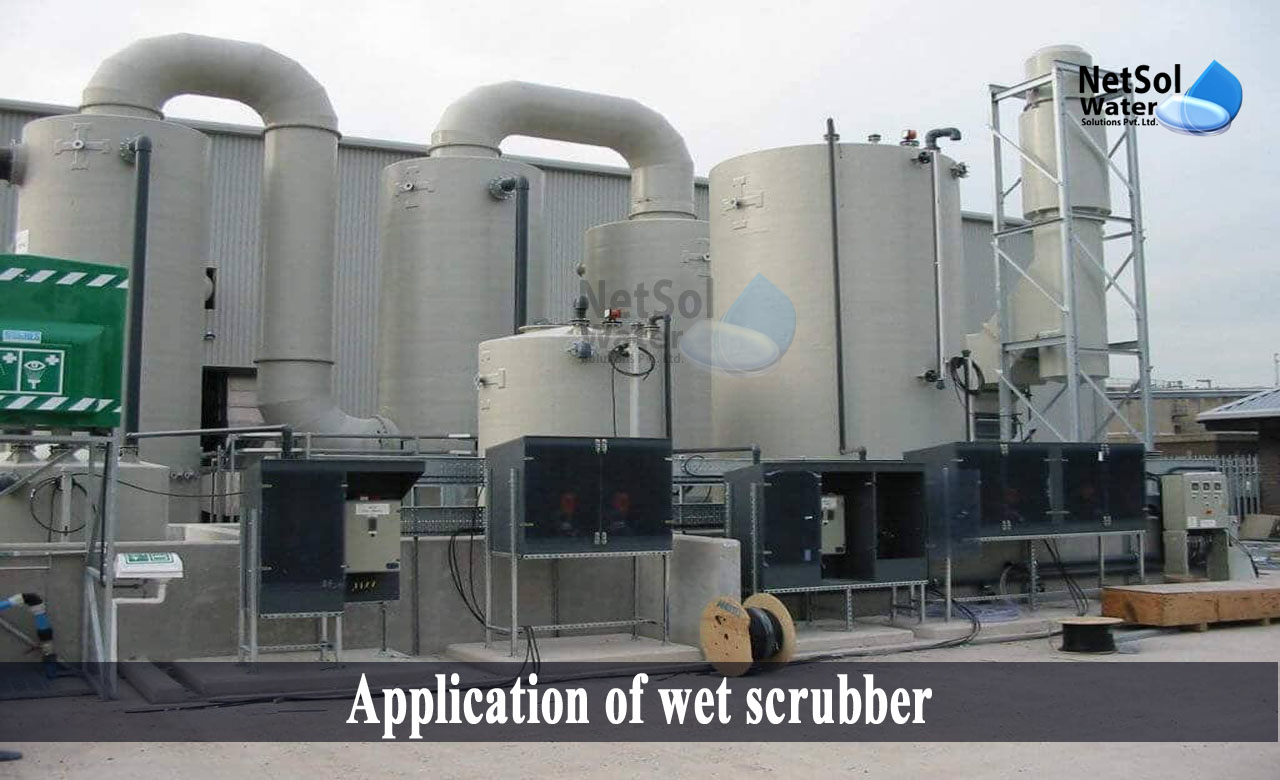

What are the Application of wet scrubber?

Wet scrubbers are required in a variety of industries since many industrial facilities emit varied air pollutants. A wet scrubber may be required in the following situations:

· Food & Beverage Production

Netsol Water is an expert in the design and construction of high-quality air pollution control systems, for the food manufacturing industry. Our primary goal is to be the preferred supplier for the Food Processing Industry's long-term demands.

Our customers include major food producers, and our systems have solved a wide range of difficult problems, including VOC and odour control, in food manufacturing and particle matter (PM 2.5 or PM 10) removal in drying and frying operations.

· Petrochemical Production

Exhaust streams from petrochemical and oil and gas processing plants contain potentially, hazardous chemical and gas residue. To remove the residue from the exhaust, wet scrubbers, chemical scrubbers, enclosed thermal flares (combustors), regenerative thermal oxidizers, and catalytic oxidizers are utilized.

We offer a complete array of scrubbers and oxidizers with contemporary, system automation that are specifically tailored to eliminate the chemical or residual waste, generated by each facility's process.

· Chemical Manufacturing

Chemical manufacturing and processing generate exhaust streams that are packed with, potentially hazardous chemical and gas residue. We offer a complete array of scrubbers, oxidizers, and flares that are designed to collect and reduce the desired emission, in the chemical process stream.

· Electroplating

Electroplating activities can emit harmful air pollutants such as heavy metals and cyanide. Toxic air pollutants and volatile organic compounds can be released by degreasing and cleaning solutions.

To eliminate the residue from the exhaust, wet scrubbers, chemical scrubbers, enclosed thermal flares (combustors), regenerative thermal oxidizers, and catalytic oxidizers are utilized.

· Acid plants

The consequences of continuous and intermittent sources of air pollution in a sulphuric acid factory are experimentally explored, resulting in the recommendation that acid plants use air pollution control technology, to reduce air pollution.

· Fertilizer plants

While, improving energy efficiency, the fertilizer industry has disregarded environmental contamination concerns. The main source of pollution at urea factories is prilling tower emissions. The emissions, which include urea dust, ammonia, nitrogen and carbon oxides, also have an impact on the growth and productivity of flora, and crops surrounding a plant.

· Steel mills

Steel production is the third-largest source of air pollution. With the greatest rates of carbon dioxide emissions, the steel sector is India's third-largest contributor to air pollution and one of the leading drivers of industrial pollution. For particulate and odour control, common air control technologies for the steel industry include Wet Scrubbers.

· Asphalt plants

Asphalt and concrete production generate a lot of particulate matter, mostly in the form of dust. The dust generated by the process might disturb the manufacturing process, and cause premature ageing and failure of equipment.

Controlling dust and pollution in asphalt concrete production facilities is critical to avoiding, hazardous situations that are harmful to workers' health. Wet air scrubbers are a viable solution to this problem. Scrubbers are air pollution control devices that remove particulate matter or gases from an industrial exhaust, or flue gas stream using liquid.

A correctly engineered wet scrubber upgrade will result in significant improvements in dust control, quality, and operational costs.

How can we assist?

Netsol Water provides service for Wet Scrubbers that require maintenance or retrofit. Our dedicated technical service section can repair or upgrade any make, model, or kind of industrial Wet Scrubber system.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.