How to design 3000LPH Commercial RO Plant for Commercial Building?

Commercial Reverse Osmosis (RO) plants are an essential component of many commercial buildings, including hospitals, hotels, schools, and office buildings. The design of a 3000LPH Commercial RO plant for a commercial building depends on several factors, including the expected water usage, the type and quantity of impurities present in the feed water, and the desired water quality.

In this blog, we will discuss the design basis, process flow diagram, and working function of a 3000LPH Commercial RO plant for a commercial building.

Design Basis

The design basis for a 3000LPH Commercial RO plant typically includes the following factors:

- Water Usage: The water usage in commercial buildings can vary widely depending on the size of the building, the number of occupants, and the facilities available. The RO plant design must take into account the expected water usage to ensure that the treatment capacity is sufficient to handle the volume of water required.

- Feed Water Quality: The quality of the feed water is a crucial factor in the design of an RO plant. The feed water may contain various impurities such as suspended solids, dissolved salts, bacteria, viruses, and other contaminants. The RO plant design must be tailored to handle the specific type and quantity of impurities present in the feed water.

- Desired Water Quality: The desired water quality depends on the intended use of the water, such as drinking water or process water. The RO plant design must produce water that meets the desired quality standards.

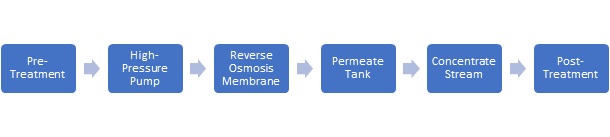

Process Flow Diagram

The process flow diagram for a 3000LPH Commercial RO plant typically includes the following steps:

- Pre-Treatment: The feed water is pre-treated to remove suspended solids and other impurities that could damage downstream equipment. The pre-treatment may include processes such as sedimentation, filtration, and disinfection.

- High-Pressure Pump: The pre-treated water is pumped to a high pressure using a high-pressure pump to force the water through the RO membrane.

- Reverse Osmosis Membrane: The RO membrane removes dissolved salts, minerals, and other impurities from the water.

- Permeate Tank: The purified water or permeate is collected in a permeate tank for further treatment or distribution.

- Concentrate Stream: The concentrate or reject stream containing the impurities removed by the RO membrane is discharged or sent for further treatment.

- Post-Treatment: The permeate may undergo post-treatment processes such as remineralization, disinfection, and dechlorination to meet the desired water quality standards.

Working Function

The 3000LPH Commercial RO plant works on the principle of reverse osmosis, which involves the separation of impurities from the feed water using a semi-permeable membrane. The pre-treatment process removes suspended solids and other impurities that could damage the RO membrane. The high-pressure pump forces the water through the RO membrane, which removes dissolved salts, minerals, and other impurities from the water. The permeate or purified water is collected in a permeate tank, while the concentrate stream containing the impurities removed by the RO membrane is discharged or sent for further treatment. The post-treatment process further treats the permeate to meet the desired water quality standards.

Conclusion

Designing a 3000LPH Commercial RO plant for a commercial building requires careful consideration of the expected water usage, feed water quality, and desired water quality. The process flow diagram and working function of the RO plant are essential for understanding the different steps involved in the treatment process and the role of each component in producing high-quality water. The 3000LPH Commercial RO plant is an essential component of any commercial building to ensure the availability of high-quality water for drinking and other uses.

For any other support, inquiries, or product purchases, call on +91-9650608473 or email at enquiry@netsolwater.com