What are the Coagulant Selection Criteria and Dosing Strategies?

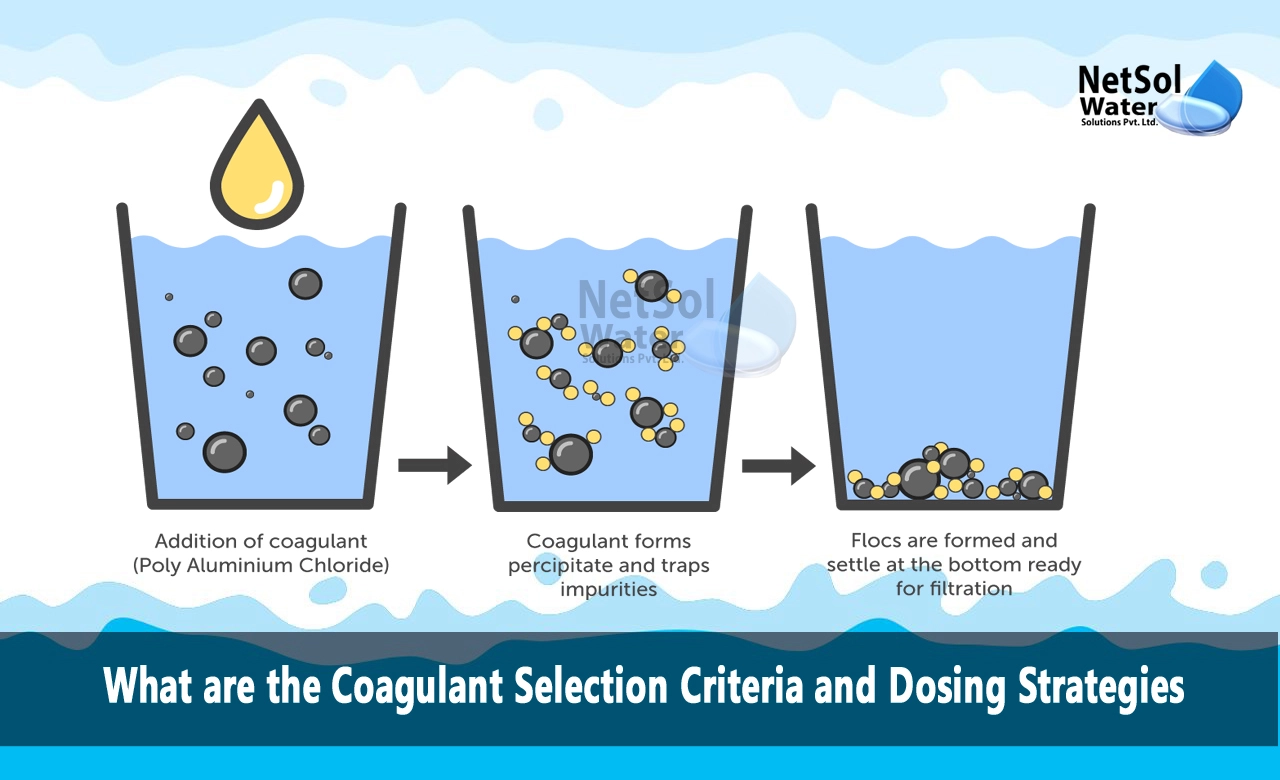

Coagulation is a critical step in surface water treatment that destabilises particles through chemical addition so they can be removed via sedimentation and filtration. The type of coagulant and dosing approach must be optimised based on source water conditions and treatment objectives. We will review key selection criteria for different coagulant options along with coagulation control strategies.

Major Coagulant Types

Aluminium and iron salts comprise the main coagulant categories, with each having different subclasses:

1- Aluminum sulfate (alum)

2- Sodium aluminate

3- Polyaluminum chloride (PACl)

4- Polyaluminum chlorosulfate (PACS)

5- Ferric sulfate

6- Ferric chloride

7- Ferrous sulfate

In addition, polymers can aid coagulation through bridging and charge neutralization. Common options include polyacrylamide, and chitosan.

Coagulant Selection Considerations

Important factors guiding coagulant selection include:

1- Raw water quality parameters like pH, alkalinity, natural organics, color, and turbidity

2- Dosage requirements and residual concentrations

3- Sludge production and properties

4- Impact on corrosivity and DBP formation potential

5- Costs and chemical availability

PACl and alum generally perform well across a wide range of conditions due to charge neutralization capabilities. Iron salts work better for low alkalinity waters. Polymers enhance coagulation performance and reduce dosage needs but can increase costs.

Dosing and Control Strategies

Effective coagulation requires optimising the dose and controlling pH to maintain proper conditions throughout treatment. Strategies include:

1- Jar testing to determine ideal coagulant dose and pH

2- Lab or online turbidity and particle counting to adjust dose

3- Streaming current detectors that measure particle charge

4- Empirical models based on water quality data

5- Automated feedback control using algorithms

Turbidity is a key parameter for assessing coagulation efficacy. However, turbidity alone does not indicate proper organics removal. Total organic carbon (TOC) analyzers can augment control.

Coagulation: The dose must be increased appropriately to compensate for variations.

Pre-polymerization involves partially reacting a coagulant like PACl or alum with some of the raw water prior to full-scale dosing. This produces larger, pre-formed flocs that aid coagulation.

Split dosing divides the coagulant dose between multiple points, allowing better control. A portion is added to the rapid mix stage while the remaining dose enters the flocculation basin.

Selective Dosing

Selective dosing entails dosing liquid PACl or alum separately from base flows. This reduces overdosing during periods of low raw water turbidity and organics. A sidestream is created using ~5-10% of the total flow, where the full coagulant dose is applied. This optimized water then recombines with the underdosed main flow prior to sedimentation.

Coagulation is a complex process requiring in-depth knowledge of raw water characteristics. While jar testing provides an initial assessment, carefully designed pilot studies give critical data on the optimal coagulant and dosing strategy. Extensive monitoring coupled with well-controlled dosing equipment can then maintain efficient coagulation as source water conditions fluctuate.

Conclusion

Proper coagulant selection and dosing control are essential for effective treatment of surface waters. Key factors like raw water quality, cost, sludge generation, and residual impacts guide the choice among commonly used aluminium and iron salt coagulants and coagulant aids. Dosing can be optimised and automated based on streaming current, turbidity, organics, and other parameters. Emerging techniques like selective and split dosing, along with pre-polymerization, allow better responsiveness to changing conditions. Maintaining skilled operations staff along with investment in dosing infrastructure and control systems helps ensure coagulation remains a robust barrier in surface water treatment.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us know your problem, our experts will make sure that it goes away.

For an assistance or s query,

Call on +91-965-060-8473 Or write us at enquiry@netsolwater.com