Industrial wastewater including silicon particles that are water soluble, and cleaning chemicals, are the principal contaminants of semiconductor cutting wastewater. Cutting wastewater is typically directly filtered into ultrapure water for reuse, because direct release will pollute the environment. Let’s see how is wastewater from the semiconductor cutting processes reused.

Rising demand in the semiconductor industries and its wastewater composition

Due to the rising global demand for electronic goods, semiconductor industries have recently emerged as one of the most significant economic drivers.

The wastewater generated frequently contains significant concentrations of anions and organic contaminants, such as fluoride, phosphate, and ammonia-nitrogen. The main causes of water eutrophication are phosphate and ammonia-nitrogen.

In addition, wastewater contains hazardous heavy metal ions, acids, and bases that are bad for the environment, and can cause skeletal fluorosis if a person consumes too much fluoride. As a result, the effluent from the semiconductor sector needs to be properly treated and disposed of. Typically, the semiconductor sector recycles its cleaned wastewater for use in facilities, such as cooling towers and scrubbers.

Methods of wastewater treatment in the semiconductor cutting processes

1: In order to remove different kinds of molecules and ions from feed water, by applying pressure to the feed when it is on one side of a selective water permeable membrane, raw water needs first be sent to the RO system. The RO recovery rate might range from 60 to 80%.

2: After RO, CEDI is used as a continuous electrochemical process. The RO product water is cleaned using a CEDI system to provide high-quality, ultra-pure water. The majority of the residual ions, including weakly ionised substances like silicates and CO2, are eliminated from the RO product water during this procedure. CEDI has a recovery rate that can reach 95%.

3: Due to the low total dissolved solids (TDS), the reject from the CEDI could typically be returned to the feed of the RO system (not more than 25–30 ppm). It should be noted that the CEDI reject could have a high concentration of ions, including boron (B), which needs additional processing before being recycled.

4: A high purity deionized water might be produced using an ion exchange system, since the reject from the CEDI system has a high ion content. Ion exchange is the temporary exchange of ions between a solid (ion exchange material), and a liquid in which the structure of the solid is not permanently altered. Additionally, it is a tried-and-true technology for recovering certain wastewaters, and metal from semiconductor production operations.

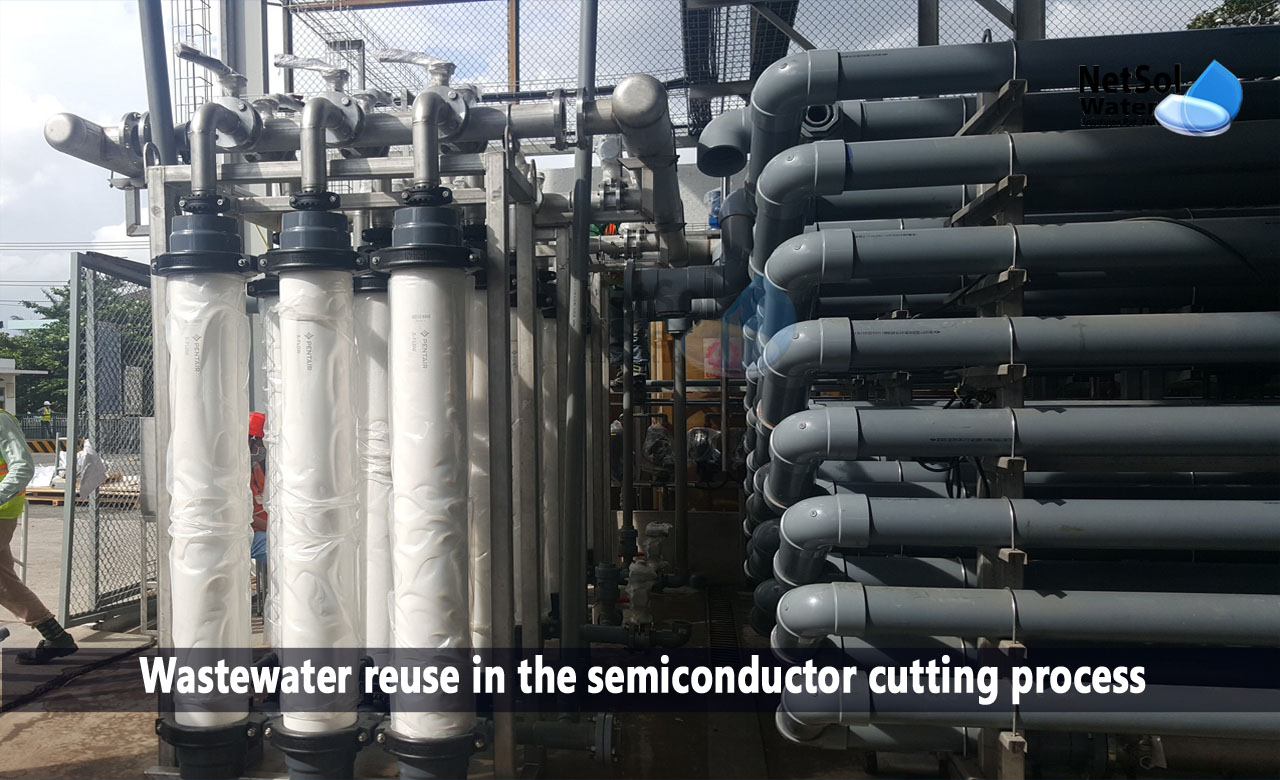

Reusing wastewater from semiconductor manufacturing through filtration

Reverse osmosis filtration, primary filtration, precision filtration, ultrafiltration, an EDI system, can be used for treating wastewater for reuse.

· Pre-filtration

In order to filter large silicon particles and some suspended material, the collected cutting wastewater is fed through a raw water pump into a filtration system.

· Primary Filtration

This filtration system is used to eliminate pollutants such tiny silicon particles in the liquid, for more thorough filtration of the filtrate after the initial filtration. It decreases the cost of filtration while extending the lifespan of the next-stage ultrafiltration system.

· Ultrafiltration

The filtrate is pumped into an ultrafiltration system using a high pressure pump for filtering treatment, in order to remove some of the grease, water-soluble silicon particles, and other impurities present in the detergent effluent. The filtrate is then added to the water tank after that.

· Reverse osmosis filtering

After being loaded into the water tank, the filtrate from the cleaning agent wastewater is forced through a high-pressure pump, into the reverse osmosis filtration system to remove any leftover water-soluble silicon particles, grease, and other impurities.

· EDI System

A booster pump introduces the liquid that has undergone reverse osmosis treatment into the EDI system, where an ion exchange technology removes the liquid's ions. After that, it is placed into a tank of highly pure water for reuse in manufacturing.

How can we assist?

Netsol Water provides design and manufacturing services to create a unique wastewater treatment plant. Whether you require a wastewater treatment plant for commercial or industrial use, we will assist you in selecting the best solution as per your need and requirement.

Contact us right now to find out more about our water and wastewater treatment products and services. All kinds of chemical, physical, and biological impurities can be effectively eliminated by our treatment systems. For further information or to make a product purchase, contact us at +91-9650608473 or drop a mail at enquiry@netsolwater.com