What is a sludge dewatering centrifuge?

One of the most critical processes in any building is sewage disposal. People and the environment health is dependent on effective and safe waste disposal and treatment methods.

For decades, the focus has been on wastewater handling in order to lower waterborne diseases and find safe ways to reintroduce solid matter into the environment. There is currently reliable equipment that can perform this process well, with improvements being made on a regular basis to improve surface water and wastewater infrastructure.

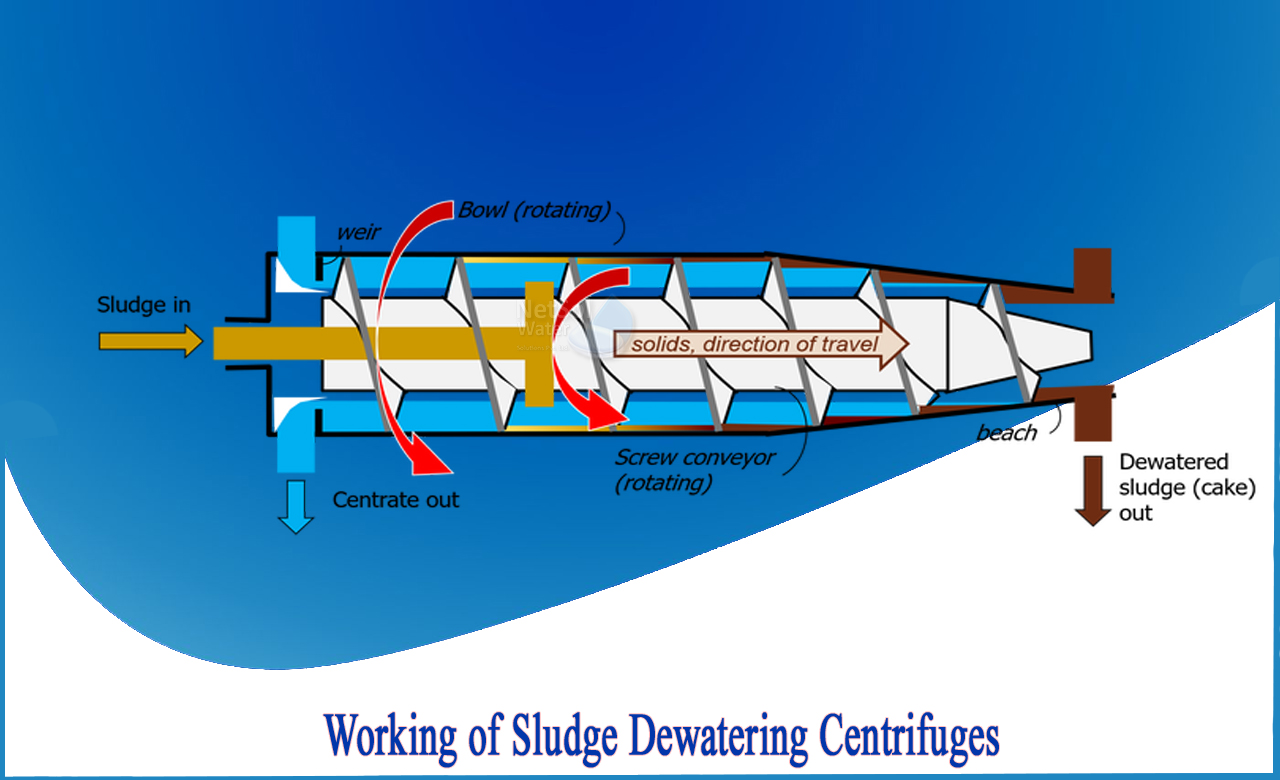

A sludge dewatering centrifuge separates wastewater liquid from solids by rapidly rotating a "cylindrical bowl." The wastewater centrifuge dewatering process removes more water than other methods while leaving a solid material known as cake behind. Dewatering reduces the amount of tank space required to store waste products.

Sludge dewatering centrifuges are essential for effective municipal waste water treatment. Residents, business owners, and government officials must learn to work with their strengths and weaknesses.

Working of sludge dewatering centrifuges:

Centrifugation is used to thicken and dewater sewage sludge, with dewatered sludge containing more dry solids (DS). Each uses nearly identical centrifuge technologies.

The following are the key operational distinctions between the two functions:

1. the rotational speed used

2. the flow rate, and

3. the composition of the concentrated solids product produced

Because more water must be eliminated to achieve higher solids concentrations, dewatering requires more energy than thickening. The dewatered product, which may contain up to 50% dry solids (DS), takes the form of a cake: a deformable semi-solid that forms lumps rather than a free-flowing fluid. As a result, it can only be conveyed via conveyor belt, whereas a thickened product retains the fluid properties of the feed and it can be pumped.

Sludge dewatering centrifuges design

The solid bowl centrifuge design can be altered to just provide greater dewatering capacity, resulting in drier solids by:

1. extending the solids outlet section's length (referred to as the beach)

2. lowering the differential velocity – the velocity difference between the screw conveyor and the bowl, and

3. modifying the screw to allow pressing of the solid cake on the beach.

The first two of these modifications lengthen the centrifuge's residence time. The third step dewaters the cake even more.

Solid bowl centrifuges are also used in a hybrid dewateringdrying process, in which the bowl is modified to allow for heating with a sweep gas. This process appears to be capable of producing DS concentrations of up to 90% from an un-thickened sludge starting material, implying that raw sludge dewatering and drying can be accomplished in a single stage.

Advantages of Sludge dewatering centrifuges design:

The centrifuge method has numerous advantages. After switching to the sludge centrifuge dewatering process, private contractors report saving approximately 75% on transportation costs and approximately 80% on disposal costs. You can keep the equipment close to the contractor's base of operations, which increases convenience and productivity.

This method's dough is simple to dispose of in a landfill, or it can be combined with green waste and composted. During a drought, you can use the filtrate on the soil, recycle it and use it through a jetting system, or discharge it to a foul system.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.