What exactly is an oil water separator Refrigeration Industries?

Simply put, an oil water separator does what the name implies: it separates oil and suspended solids from wastewater so that they can be skimmed away. Because oil is lighter than water, it tends to float to the surface. However, due to the nature of wastewater, which contains a wide range of contaminants, some oil particulates, particularly tiny droplets, can become entangled.

Oil water separators are specifically designed to target oil based, on the gravity difference between oil and water, allowing heavier solids (sludge) to settle to the bottom and oil to rise to the top, leaving additional wastewater in the middle layer. Sludge can then be scraped away, oil can be skimmed off the top, and wastewater can be transported to a treatment facility.

Refrigeration Industries

Supermarkets are an excellent example of a business that would benefit greatly from a water oil separator system. Because refrigeration systems operate at extremely low temperatures, a water oil separator system is installed in the compressor to assist the evaporator in receiving the returned oil.

How does it operate in Refrigeration?

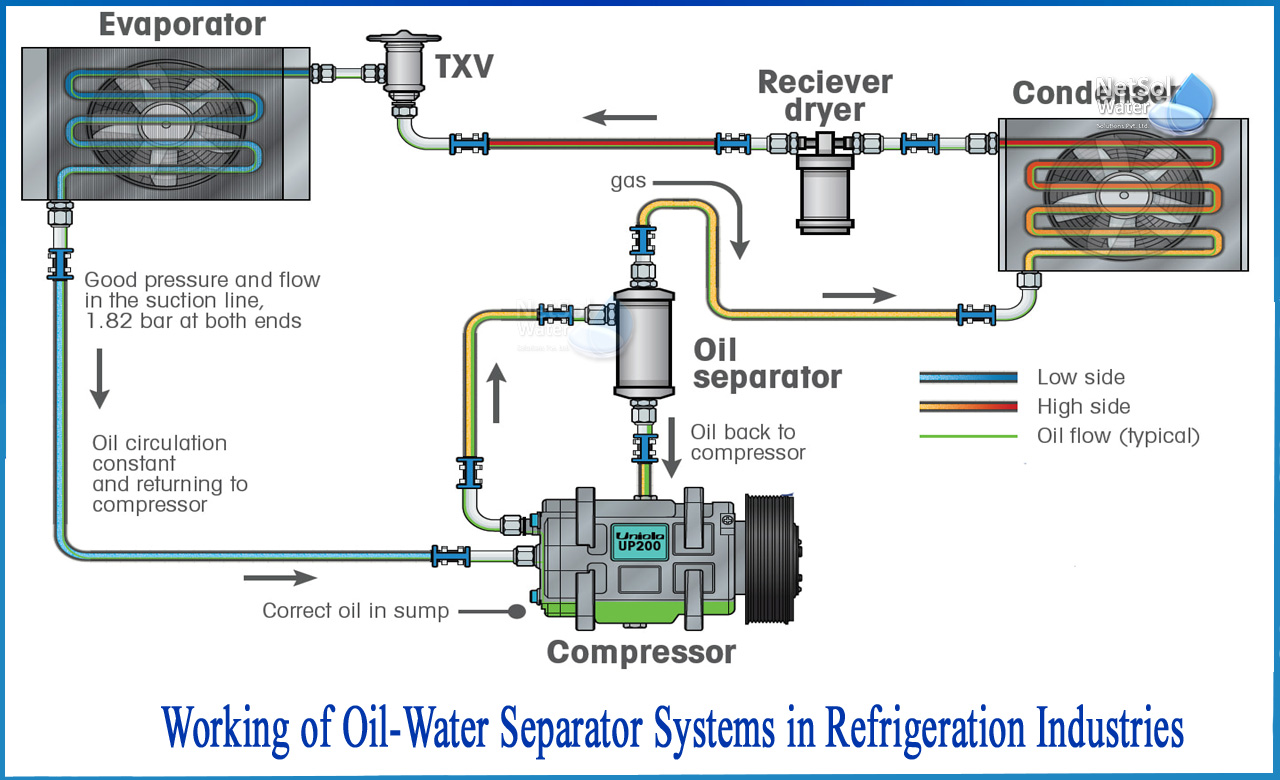

Except for centrifugal compressors, all refrigeration compressors contain oil, which lubricates the compressor and forms seals between the moving parts during compression. The oil is necessary for high compressor efficiency, but it has a negative impact on heat transfer in the system.

The oil separator is on the system's high side, and the compressor crankcase is on the system's low side. This float-operated oil return needle valve is high enough in the oil sump to allow clean oil to be returned to the crankcase automatically.

After passing through filters to remove the largest solids, the wastewater is routed into the oil water separator for treatment. In most cases, wastewater is routed through a series of chambers. These chambers aid in the separation of oil, water, and sludge into three distinct areas. Heavy sludge and suspended solids settle at the bottom.

Oil particulates are tumbled over the surface of the wastewater as it passes through the chambers, allowing them to collect and form larger globules, increasing buoyancy. As a result, more oil separates and rises to the surface of the wastewater.

Why is it necessary to separate oil and water? What is the issue with oil? Why is it necessary to separate it from water?

Simply put, it can be hazardous to the environment. Oils in wastewater can include not only the cooking oils and grease that homes, restaurants, and other commercial establishments flush down the drain, but also petroleum and other hazardous products. These have the potential to disrupt ecological systems and harm plants, animals, and even humans.

Conclusion

Get in touch with our experts to have a complete knowledge about the type of oil water separator best suitable for your business establishment. We have solution for all your problems and a product for your every need.

Netsol water, wastewater and waste management experts will treat your system and proactively respond to your needs like they’re our own. Our mission is to make the world’s waste management systems affordable, sustainable as well as energy efficient.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.