Why Treated Wastewater Often Fails Reuse Applications?

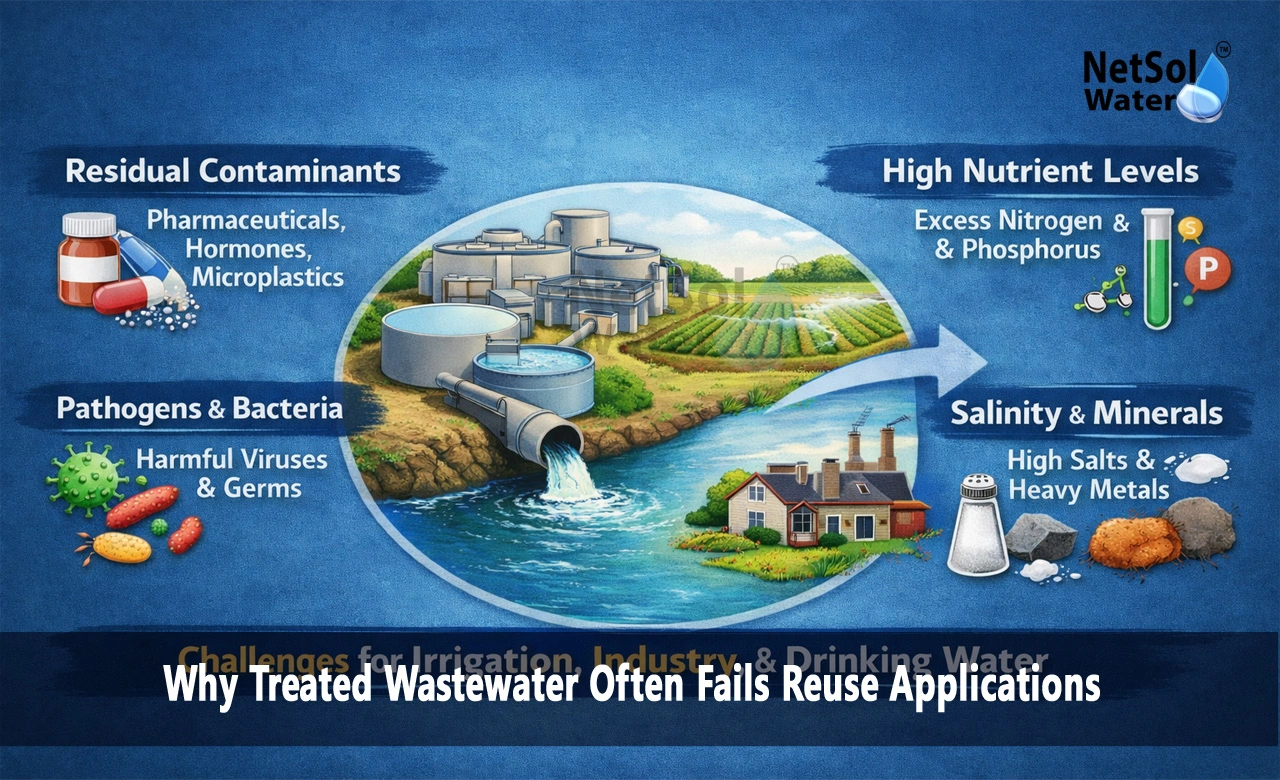

As water becomes scarcer and more control mechanisms are enforced, reusing wastewater has since emerged as a key aspect of sustainable water management. Most sewage treatment plants and effluent treatment plants are constantly in compliance with the discharge norms but still the same treated water does not perform in most cases when applied as irrigation, cooling, flushing and industrial usage. This brings about confusion among the operators of the plants and project owners who take compliance with the regulations as a guarantee that reuse is suitable. As a matter of fact, treated wastewater often fails reuse applications because of deeper water quality, design and operational discrepancies than typical compliance standards allow.

Disagreement between Discharge Standards and Reuse Requirements

1: Discharge Norms not Reuse Norms

The majority of treatment systems are created to comply with the discharge limits related to BOD, COD, and TSS. Reutilization applications require another quality profile that encompasses such parameters as the stability of turbidity, nutrient ratio, salinity regulation, microbial safety, and aesthetics. Legally compliant water may be used as re-useable water but can cause fouls, corrosion, odor or health hazards.

2: Incomplete Concentration on Dissolved Contaminants

Traditional treatment methods are useful in the removal of suspended solids and biodegradable organics but usually leave dissolved salts, nutrients, trace organics, and remnant chemicals. These pollutants are stored up in the reuse cycles and the water is therefore not suitable to be applied over the long term despite the fact that minimum treatment objectives have been achieved.

Why Treatment Processes are not effective in Reuse?

1: Biological Treatment is Not Reuse Stable

Biological systems are designed to reduce the organic loads, and not water consistency. Change in influent load, temperature and microbial action result in change in quality of treated water. In the case of reuse application, any slight change in turbidity or nutrient content may lead to the clogging, scaling, or biological growth in the downstream systems.

2: Lack of proper elimination of Nutrients

In standard treatment setups, nitrogen and phosphorus are also likely to be partially extracted. Although this is acceptable to discharge, the remaining nutrients promote the growth of algae, biofilm growth, and odor problems in storage tanks and reuse pipelines. This is a significant cause as to why treated wastewater does not typically work in reuse in irrigation systems and in cooling systems.

3: Microbial Risks Other than the BOD Reduction

Low BOD does not indicatesafety of the microbes. After biological treatment, the pathogens, viruses, and resistant bacteria could still be present. The applications that involve human contact or aerosol generation require further disinfection and monitoring which is not consistently offered in many plants.

Operation Factors that weaken Reuse Performance

1: Hydraulic Overloading and Short-Circuiting

The size of many treatment plants is increased beyond capacity. High flow rate causes decrease in effective retention time resulting into incomplete treatment. Where lab samples can sometimes cross limits, the general quality of water is not as reliable as required by reuse systems.

2: Sludge Management Poor Practices

It is caused by poor solids removal that results in solids carryover and increased turbidity of the treated water. This leads to filter foulage, pump wear and blockage of distribution lines in the reuse networks when average TSS values seem to be within compliance.

3: Weakly Consist?ent Disinfection Control

The disinfection systems are usually run in a reactive manner and not as part of the reuse planning. Under-dosing does not eliminate pathogens, whereas over-dosing may add chemical leftovers that destroy gear and influence the development of plants in reuse of irrigation.

Limitations in Design of Reuse Treatment

· Absence of Stages of Polishing Treatment: The filtration, adsorption, or advanced oxidation polishing units are required to be reuse-ready to stabilize the water quality. Most of the plants do not have such stages as they are not designed to be reused either internally or externally.

· None Salinity Management Provision: One of the least considered reuse limitations is salinity. The total dissolved solids and sodium adsorption ratio have a direct influence on soil structure, cooling efficiency and membrane performance. Unless treated wastewater is controlled specifically, it is gradually becoming unfit to be reused even though it is within the organic limits.

· Lack of Storage and Quality Buffering: Reuse requires good consistency in quality but majority of the plants release water as soon as treatment is done. In the absence of balancing tanks or buffer storage, short-term quality upsets directly get into reuse systems and cause frequent failures and dissatisfaction with the system.

Why Monitoring and Control are Frequently Ineffective?

1: Limited Parameter Tracking

Compliance parameters are monitored regularly instead of reuse critical parameters such as turbidity trends, nutrient ratios, residual disinfectants and conductivity stability. This causes areas of blindness wherein the reuse failures are built up overtime and remain unknown until they cause damages.

2: Operation reactive as opposed to preventive

A majority of the treatment plants are reactive rather than preventive. When problems of reuse become evident, equipment contamination, microbial growth or corrosion has already set in, leading to a higher cost on corrective measures and downtime.

What Does It Take to achieve Success in Reuse?

The treated wastewater can only satisfy reuse needs as long as reuse is the ultimate goal of designing and operation of the systems. This is through aligning treatment objectives with end-use requirements, stabilizing the water quality by polishing the water, controlling the nutrients and salinity and adopting proactive monitoring. The success of reuse is not determined by the low BOD values but rather provision of predictable and consistent and application-specific water quality.

Conclusion

One of the most widespread myths about wastewater management is the assumption that compliant treated water can be reused on the assumption that it is automatically safe. Reuse applications by using treated wastewater do not succeed as the treatment agencies are designed to discharge, but not to perform reliably and effectively to control dissolved contaminants and maintain consistency in operation. The only way to address this gap is to move the design philosophy, track priorities and discipline in operations. Treated wastewater can be considered a valuable source when its reuse is planned, as opposed to being a challenge to be encountered on a regular basis.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us know your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-9650608473 Or write us at enquiry@netsolwater.com