Why is zero liquid discharge important?

The term "zero liquid discharge" (ZLD) refers to a technical method of treating water, in which all water is recovered and contaminants are turned into solid waste. While many water treatment technologies aim to enhance freshwater recovery and minimize waste, ZLD is the most difficult goal to achieve, because recovery costs and difficulties rise as wastewater concentrations rise. The combination ofvarious water treatment technologies, can handle wastewater, if the toxins are concentrated, resulting in Zero liquid discharge systems.

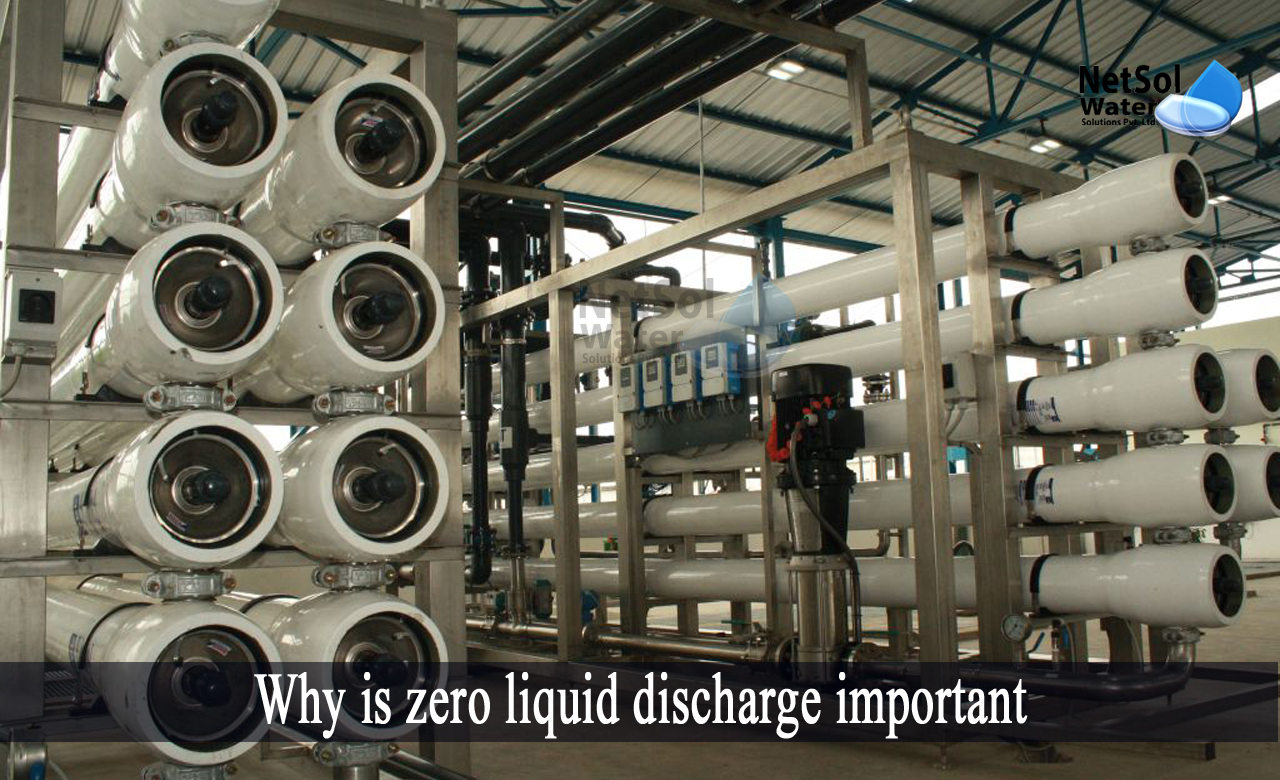

Importance of Zero Liquid Discharge (ZLD) systems

Freshwater availability is under threat from industrial operations. Water is needed for many industrial operations, but as a result, less water is available for the environment or other processes, or alternatively, contaminated water is released into the environment, causing harm.

India has established policies that demand zero liquid discharge, due to industrial wastewater's substantial pollution of significant rivers. The high costs of wastewater disposal at inland plants have pushed India, towards zero liquid discharge. Regulations that restrict disposal options and variables, affecting the expense of disposal technologies, also contribute to these costs.

The possibility of recovering resources from wastewater is a crucial justification, for zero liquid discharge. Some businesses concentrate their waste at ZLD, because they can make money off the created solids, or utilize them in their industrial processes.

For an industrial process or facility, aiming for zero liquid discharge, has a variety of advantages:

· Reduced waste quantities lower the expense of waste management.

· It reduces the cost and risk of water acquisition by recycling water on the spot. In comparison to treating to fulfil strict environmental discharge regulations, on-site recycling can also result in less treatment requirements.

· Reduces the number of trucks needed for off-site waste water disposal, as well as the accompanying greenhouse gas emissions, and danger of neighbourhood traffic accidents.

· Some procedures can salvage valuable resources, like sodium chloride salt for ice melting, or ammonium sulphate as a fertilizer.

Whatever the organization's reasons for aiming for zero liquid discharge, doing so indicates sound business practices, corporate accountability, and environmental stewardship.

Conclusion

To emphasize that they release low quantities of wastewater, but do not completely eradicate liquid in their waste, some engineers refer to such designs as near-zero liquid discharge, or minimal liquid discharge. By concentrating brine to smaller amounts, it can be more cost-effective for some facilities to get close to ZLD, without actually achieving it. Furthermore, by carefully conserving water, or by removing contaminants at their source, before they may contaminate the main water flow, it may be able to prevent the production of liquid waste on-site.

How can Netsol Water assist?

We have an experience of over 10 years, in the water and wastewater treatment, as well as, expertise in custom-designing and producing Zero Liquid Discharge systems. We can guide you through the process of coming up with the best solution, and a reasonable price for your ZLD treatment system requirements.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.