Composting of Sewage Sludge from Treatment Plants

As populations grow and wastewater treatment expands, the volumes of nutrient-rich sewage sludge produced at municipal facilities continue increasing in parallel. Rather than viewing this biosolids stream as a disposal liability, many innovative utilities have implemented composting as a sustainable solution for transforming sludge into a valuable soil amendment product.

Let's know about the composting process and key considerations for effectively composting dewatered sewage sludge.

The Composting Process

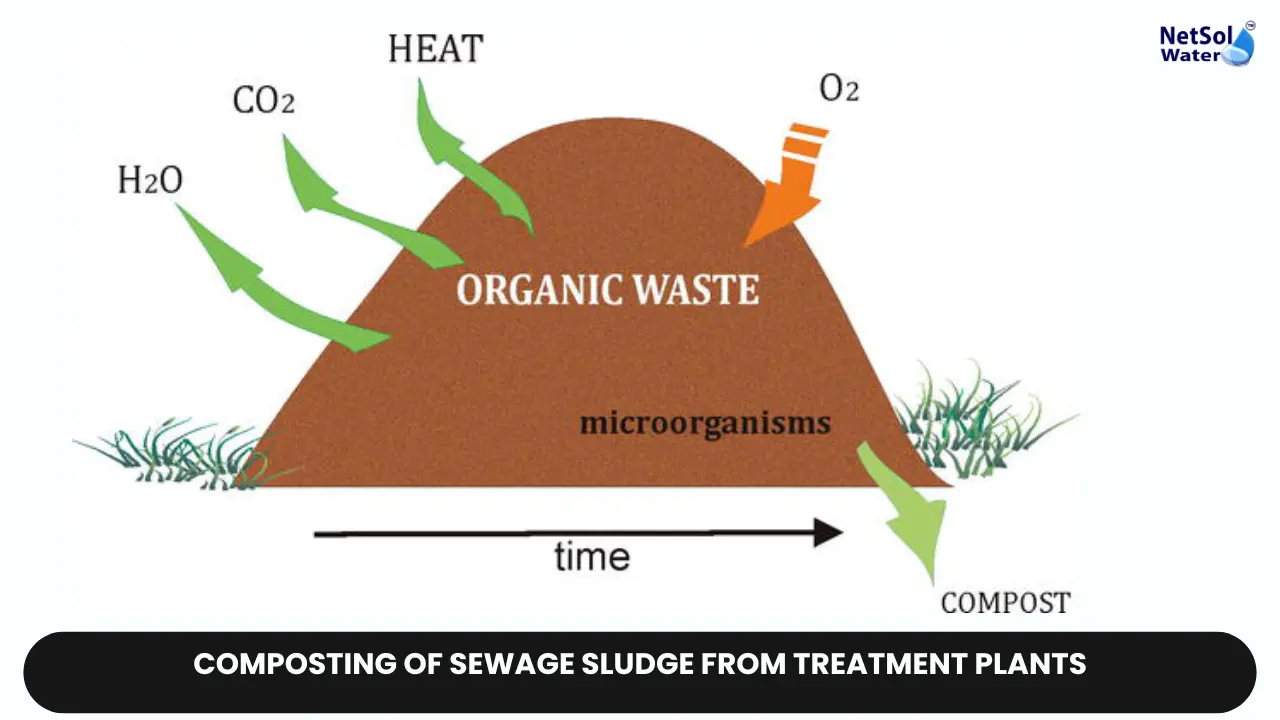

Composting involves harnessing natural biological decomposition and heat generation to transform organic solid waste streams like sewage sludge into a stable, humus-like material rich in plant nutrients. Dewatered sludge cakes from belt presses or centrifuges make ideal feedstocks with optimal moisture content of around 60-70%. The sludge is mixed with a carbon-rich bulking agent like woodchips or yard trimmings to establish the proper carbon-to-nitrogen ratio around 25-30:1. This mixture is stacked into elongated, aerated piles or channels called windrows.

Active Composting Phase

During the initial mesophilic stage, microbes quickly break down the readily available organic compounds in the sludge/bulking agent blend, generating heat and carbon dioxide. As temperatures rise above 105°F, thermophilic bacteria take over and continue to decompose complex proteins, fats, and celluloses. Maintaining aerobic conditions by regularly turning or forcing aeration through the windrows promotes optimum microbial activity and temperature elevation to around 140°F. This intense heating sanitises the compost and destroys pathogens and weed seeds.

Curing and Finishing

After several weeks, once available nutrients are depleted, the active heating phase subsides. The compost then enters a curing stage where remaining materials like lignin and cellulose continue degrading at cooler temperatures via fungal activity. Gradually reducing porosity through pile compaction allows the compost to dry. After 60-90 total days, the cured compost is screened to produce a stabilised, humus-rich soil amendment meeting EPA criteria for contaminant levels and pathogen reduction.

Mitigating Odors

Effective odour management is crucial for any sludge composting operation, as partially decomposed sludge emits offensive volatile compounds like ammonia, amines, sulfides and volatile fatty acids. Maintaining aerobic conditions through proper windrow construction and regular turning minimises odorous anaerobic zones. Biofilters like wood chips or compost-covered plenums can absorb residual fugitive odours onsite. Enclosing portions of the process and alkaline amendments may be required at larger facilities.

Enhancing Operation Efficiency

Various enhancements optimize the efficiency and quality of sludge composting operations. Blending in materials like nutrient fertilizers and inoculating with specialized bacterial starters accelerates decomposition rates. Automating equipment like windrow turners and aeration control systems improves labour productivity. Covered aerated bunkers provide indoor odour containment in humid climates. Integrating bag houses and acid scrubbers captures any emissions. Leachate collection and recycling conserves moisture while reducing runoff volumes requiring treatment.

Marketing Products

The final key component involves developing successful markets for the Class A Biosolids-derived compost. Many states now mandate diverting sludge from landfills while promoting compost utilisation for agricultural soil amendments, horticulture, landscaping, construction projects, landfill cover and more. Establishing distribution partnerships with private companies can enable reaching diverse bulk and retail customers across industries. Packaging operations provide bagging options for homeowners. Ultimately, creating closed-loop cycles returning nutrients to soils provides a sustainable implementation model.

Conclusion

Implementing sewage sludge composting programs allows wastewater utilities to transform a traditional disposal liability into a marketable soil amendment product, closing nutrient cycles in communities. While odours, pathogen vectoring and following EPA regulations represent hurdles requiring intensive management, composting represents a promising route for diverting biosolids from landfills and reducing associated greenhouse gas emissions. As the public demand for environmentally conscious sludge handling grows, composting will likely continue emerging as an increasingly common biosolids strategy.

To explore customised commercial RO plants, Industrial RO plants, ETP or STP solutions for your needs in your areas and nearby regions, contact Netsol Water at:

Phone: +91-965-060-8473

Email: enquiry@netsolwater.com