Waste disposal and water recovery for reuse

Zero Liquid Discharge (ZLD), is a treatment method, whicheliminates all liquid waste from a treatment system. The purpose of ZLD water treatment is to decrease effluent, while producing potable water suited for everyday consumption. A zero-discharge system is a sophisticated treatment technology, which includes ultrafiltration, reverse osmosis, evaporation, and fractional electro-deionization.

In this blog, we will discuss about the design of ZLD systems, and the factors on which they are based.

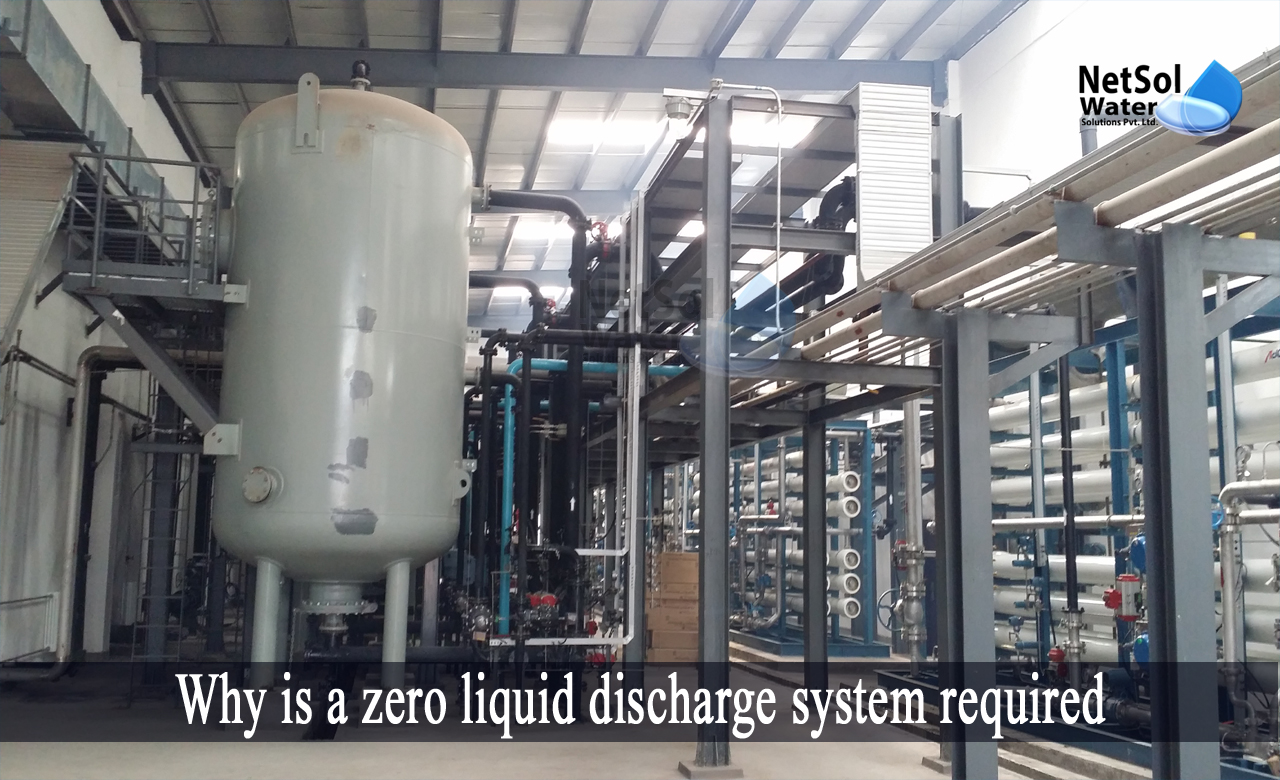

Why is a zero liquid discharge system required?

Many industries, including electricity, oil and gas, chemicals, mining, and others, create a huge volume of wastewater that must be treated.Typically, wastewater is discharged by a plant outfall to a surface water body, such as an evaporation pond, or, in rare situations, deep injection wells. As water is a precious resource, these activities raise significant environmental concerns among the general population, in many parts of the world. Many industries have used ZLD methods to reduce their environmental footprint, and improve sustainability, as a result of these concerns.

To secure the future of their rivers and lakes, ZLD has become essential in India during the last decade, due to substantial pollution of local waterways by industrial effluent.The high costs of wastewater disposal at inland facilities, have increased the need for ZLD in India.

Technologies used in ZLD systems

· Concentrators of Falling Film Brine

· Crystallizer with Forced Circulation

· Evaporator with Horizontal Spray Film

· Membrane Pre-Concentrators in Hybrid Systems

· Biological Treatment

· Handling of Solid Waste

Benefits and applications of the zero liquid discharge system

· Production of potassium sulphate (K2SO4) fertilizer, from salt mines

· It reduces the cost of coal mine wastewater treatment, by recovering pure sodium chloride, which may be marketed as road salt.

· It reduces the volume of wastewater, while lowering waste management expenses.

· On-site water recycling reduces the demand for water input, while satisfying treatment standards.

· It reduces truck transportation expenses for off-site disposal, and the associated environmental risks.

ZLD system designs factors

What are the aspects that must be addressed when designing ZLD systems?

They are as follows:

· The pollutants present in the discharge stream,

· The dissolved material's volume,

· The necessary design flow rate.

Parameters of concern for zero liquid discharge (ZLD) systems

The zero liquid discharge system requires careful consideration of water chemistry, such as

· Sodium

· Potassium

Design of the ZLD system

Regardless of th?e number of wastewater sources, a ZLD system typically consists of two phases.

A: Pre-concentration: Pre-concentration of brine is acquired mostly, through the use of membrane brine concentrators. These technologies may recover 60-80% of the water.

B: Evaporation/Crystallization: The following process, evaporation, collects and directs all remaining water for reuse. The residual waste is then sent to a crystallizer, which boils all of the water, until all of the impurities crystallize and are filtered out as a solid.

Manufacturers of Zero Liquid Discharge (ZLD) Plants in India

Netsol Water, based in Greater Noida, India, is a well-known manufacturer of water and wastewater treatment systems. We are well-known for being the top commercial RO plant manufacturers, industrial RO plant manufacturers, ZLD Plants, sewage treatment plant manufacturers, Water Softener Plant Manufacturers, effluent treatment plant manufacturers, and much more.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.