What is difference between Sedimentation and Flotation?

Flotation in wastewater treatment

Flotation is a separation technique that employs the use of gas bubbles as a transport medium.

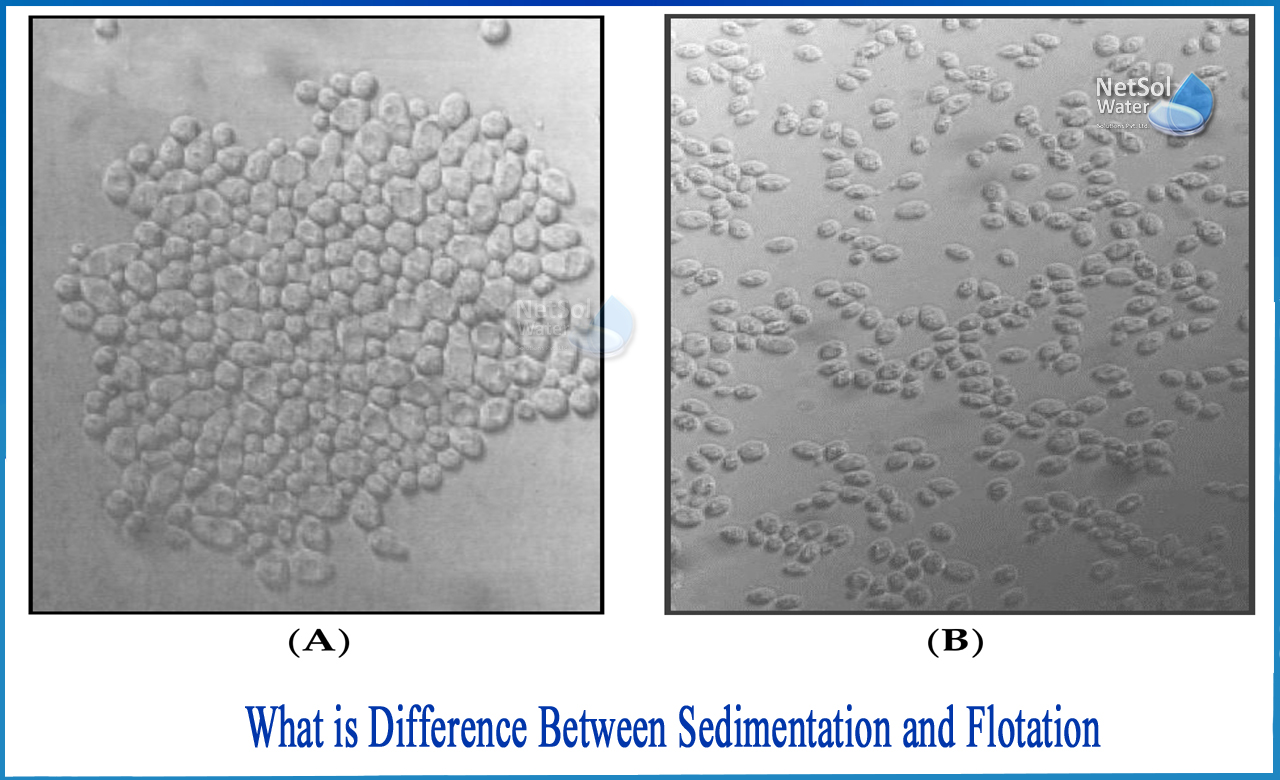

Suspended particulate matter that is hydrophobic or has been conditioned to be hydrophobic attaches to the bubbles and flows in the opposite direction of gravity towards the aqueous solution surface.

Dispersed-air flotation (or froth, in mineral processing) techniques, which frequently incorporate electroflotation, and dissolved-air flotation (DAF), which is based on Henry's law, are two types of bubble formation methods. The flotation method, as well as the related scientific data required to examine and describe the separation mechanism involved, has traditionally come from the field of mineral processing.However, the process has a variety of uses, including the utilization of sorbent materials and chemical parts such as collectors, frothers, and modifiers upstream.

As proven by several cases, chemistry knowledge can aid in flotation separation!

Because a wide range of heavy metal-bearing waste streams must be treated, hazardous metals may cause significant environmental harm due to their solubility and mobility.

Modern Coagulation-Flocculation methods

Microplastics (plastic particles less than 5 mm) are removed from effluent in municipal wastewater treatment plants using various modern final stage treatment technologies, including flotation.

For the fast removal of tetracycline antibiotics from wastewater, a coagulation-flotation approach (containing an anionic surfactant and a cationic polyelectrolyte) can be developed. Broad-spectrum antibiotics are routinely utilized in cattle production and are frequently prescribed for human treatment. Also, and maybe unavoidably, petroleum refining produce vast amounts of greasy effluent. All these can be removed from proper techniques of oil-water separation, coagulation-flocculation, etc.

Sedimentation in wastewater treatment

The process of sedimentation is when particles suspended in water or wastewater are allowed to settle out of suspension due to gravity. The particles that settle out of the suspension form sediments, which is referred to as sludge in the water or wastewater treatment industry.

Consolidation occurs when a heavy layer of silt continues to settle. Thickening occurs when silt, or sludge, is aided in its compaction by mechanical means.

Sedimentation can be used in water or wastewater treatment to lower particle concentrations in suspension before coagulation, to reduce the amount of coagulating chemicals required, or after coagulation and perhaps flocculation.

When sedimentation is used after coagulation, the goal is usually to lower the concentration of solids in suspension so that filtering can work as efficiently as possible.Prior to filtration, sedimentation is one of numerous alternatives for applications; other options include dissolved air flotation and various filtration processes. These solids-liquid separation operations are referred to as clarifying processes in general.

Sedimentation tanks come in a variety of Shapes and Sizes

· Tanks with a horizontal flow;

· Tanks with a radial flow;

· Settling on an inclined plane;

· Sedimentation with ballast;

· Floc sedimentation blanket.

What do we offer?

If you are curious to know more about the sedimentation process and how to enhance the quality of water and wastewater, then you are at the right place!

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.