Why Clarifiers Used in Sewage Treatment Plants?

Sewage treatment is a multi-stage process to remove contaminants from wastewater before discharge or reuse. Among the critical unit operations, clarification plays a vital role in primary and secondary treatment by separating settleable solids from liquid streams. Clarifiers leverage principles of sedimentation and flotation to extract suspended matter efficiently. Different clarifier designs tailored to various treatment contexts facilitate optimal solids removal while minimising footprint and costs. As key precursors to subsequent treatment processes, properly designed and operated clarifiers are essential for overall plant performance and effluent quality.

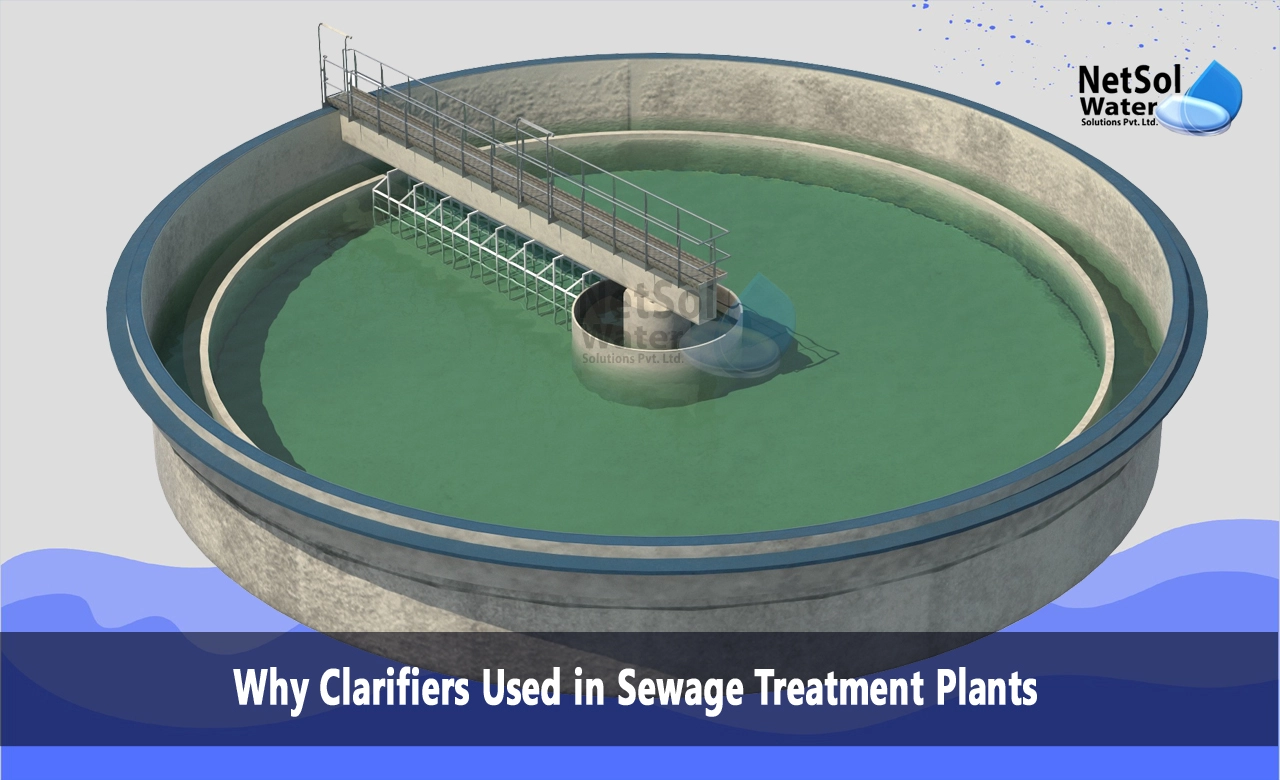

Primary Clarification

The initial clarification stage following screening/grit removal is primary sedimentation in rectangular or circular clarifiers. These large basins allow heavier solids like faeces, food waste, and inorganic grit to settle out through gravity. Well-designed inlet structures minimise turbulence and short-circuiting, while sludge collector mechanisms continuously remove settled sludge. Primary clarifiers typically remove 50-70% of total suspended solids (TSS) and 30-35% of biochemical oxygen demand (BOD) from raw sewage. Higher surface overflow rates in smaller footprints can be achieved by adding tube settlers or inclined plate packs. Reliable primary clarification protects downstream treatment processes.

Secondary Clarification

Following biological treatment where microbes metabolise dissolved/suspended organics, secondary clarification separates activated sludge biological mass from clarified liquid effluent. Secondary clarifiers share similarities with primary designs but require different considerations for optimal performance. Sufficient surface area minimises rising/dislodgment of microbial floc under design flow conditions. Mechanical collection equipment like skimmers, shovels, or suction withdraws thickened sludge without disturbing settled sludge blankets. Sludge recycle pumps control mixed liquor suspended solids underflow, concentrating biological mass for re-aeration. Full-scale secondary clarifiers produce effluent with under 30 mg/L TSS and BOD.

Membrane Bioreactor (MBR) Clarification

An increasingly popular secondary treatment approach uses membrane clarification instead of conventional secondary clarifiers. Membrane bioreactors combine activated sludge treatment with micro/ultrafiltration membranes directly immersed or in sidestream configurations with biological reactors. While more energy-intensive, membranes achieve extremely high solids removal down to 0.1 μm, producing exceptionally high-quality effluent. This allows higher mixed liquor biomass concentrations, enhancing treatment capacity. Membranes enable smaller footprints than conventional clarifiers while also eliminating sludge-settling issues. Air scouring manages fouling.

Tertiary Clarification

Where additional treatment beyond secondary clarification is required, various tertiary clarifier configurations provide advanced solids-liquid separation. Conventional tertiary clarifiers share similarities with primary designs. However, some utilise different driving forces rather than just sedimentation. For example, dissolved air flotation clarifiers induce suspended matter to be skimmed from liquid surfaces, while ballasted clarification uses micro-sand to weigh materials, enhancing their settling. Tertiary clarifiers produce exceptionally low TSS in effluent amenable for filtration/disinfection to achieve ultrapure discharge or high-quality water reuse.

Clarifier Instrumentation and Controls

Clarifiers require reliable measurement instrumentation and automated control systems to operate optimally. Position sensors monitor rotating mechanisms, while level sensors in effluent channels detect sludge blanket levels, informing concentration adjustments. Sludge blanket sensors using laser, sonic, or radiometric measurements detect blanket heights triggering sludge draw-off based on concentration setpoints. Turbidity and suspended solids monitoring validate effluent quality. Differential pressure sensors identify abnormal head losses indicating blockages. Modern control platforms analyse all performance data, adjusting pumps, mixers, air supplies, and sludge removal accordingly.

Netsol Water's Advanced Clarifier Solutions

Netsol Water offers cutting-edge clarifier products for both municipal and industrial treatment designs. Netsol Water’sspeciality inclined plate clarifiers for tertiary polishing leverage enhanced plate designs and computational fluid dynamics modelling for ultra-high hydraulic throughputs. All clarifier products seamlessly integrate into customised treatment trains.

Conclusion

Effective clarification is foundational to sewage treatment plant performance across all stages - from primary solids separation to biological secondary treatment to tertiary effluent polishing. The right clarifier selection matched to each application context optimises removal efficiencies, throughput capacities, and costs. While conventional circular clarifiers remain widely used, emerging technologies like membrane bioreactors (MBRs) and advanced tertiary clarification systems provide compelling advantages for challenging treatment scenarios or compact footprint constraints. Integrating automated monitoring and controls further enhances clarifier optimisation. As wastewater treatment demands increase amidst tighter discharge regulations, sewage plants can rely on innovative clarifier solutions to ensure consistently reliable performance.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.