What is Zero Liquid Discharge and What are the benefits of ZLD?

Not all industrial facilities that create wastewater need a Zero Liquid Discharge facility (ZLD). It is typically considered as a last option, because it can be a difficult process with a hefty upfront cost.It might be worthwhile to pursue it, if a facility is situated on a site with severe water scarcity problems, or exorbitant discharge fees, but if it's not required, careful consideration must be given.

If zero liquid discharge (ZLD) is a requirement at your facility, or it is something you're thinking about, you might be curious to know what ZLD is and what are its benefits?

I've broken down and simplified the complicated response to this issue for you!

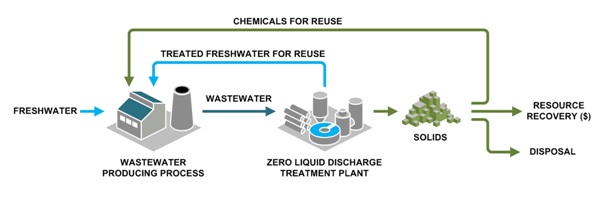

What is a zero liquid discharge treatment system?

A ZLD treatment system uses cutting-edge modern water treatment procedures, to reduce liquid waste at the conclusion of your industrial process to zero. It is an approach to wastewater treatment, which combines fractional electro-deionization, evaporation, crystallization, reverse osmosis, and ultrafiltration.

A ZLD treatment system that is effective and properly thought out should be able to:

· Adapt to fluctuations in the flow and contamination of waste,

· Allow for necessary changes to chemical amounts,

· 95% or more of your liquid waste can be recovered for reuse,

· Treat your waste to recover useful by-products (i.e. salts and brines),

· Create a solid, dry cake for disposal.

Advantages and benefits of Zero Liquid Discharge (ZLD)

For an industrial process or facility aiming for zero liquid discharge, it receives a variety of advantages, including:

· Reduced waste quantities lower the expense of waste management.

· Reduces the cost and risk of water acquisition by recycling water on the spot.

· In comparison to treating to fulfil strict environmental discharge regulations, on-site recycling can also result in less treatment requirements.

· Reduces the number of trucks needed for off-site wastewater disposal, as well as the accompanying greenhouse gas emissions, and danger of neighbourhood traffic accidents.

· Some procedures can salvage valuable resources, like sodium chloride salt for ice melting, or ammonium sulphate fertilizer.

What components make up a fundamental ZLD treatment system?

The precise parts of a ZLD treatment system will largely depend on:

(1) The amount of dissolved material present in the waste,

(2) The flow rate needed for the system, and

(3) What specific contaminants are present?

But often, a fundamental ZLD treatment programme consists of some combination of:

· To precipitate out metals, hardness, and silica, Netsol water uses a clarifier or reactor.

· Precipitation, flocculation, or coagulation is used, to assist with any metal and suspended particles.

· To concentrate any secondary solid waste, a filter press in conjunction with an evaporator is used.

· In order to eliminate all remaining trace amounts of suspended particles, and avoid fouling, scaling, or corrosion farther along the treatment line, ultrafiltration (UF) is used.

· In the initial stages of concentration, reverse osmosis (RO) is used to remove the majority of dissolved particles from the water stream.

· Brine concentrators are used to further concentrate the electro-dialysis, or reject from RO stream to concentrate the waste stream, and minimise waste volume.

· Evaporator is used in the final stages of waste concentration, before the crystallizer, to vaporise access water.

Conclusion

These standard components are typically sufficient depending on the requirements of your plant and process, but if your plant needs a system that offers a little bit more customization, you could need to add additional features or technologies. ZLD is a highly customized process, because of the wide range of industries it is used in and the diverse waste streams it produces, and these add-ons will vary depending on your facility's specific requirements.

How can Netsol Water assist?

We have an experience of over 10 years, in the water and wastewater treatment, as well as, expertise in custom-designing and producing systems, including Zero Liquid Discharge. In order to schedule a call with an engineer, or submit a quote request, you can also visit our website. We can guide you through the process of coming up with the best solution, and a reasonable price for your ZLD treatment system requirements.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.