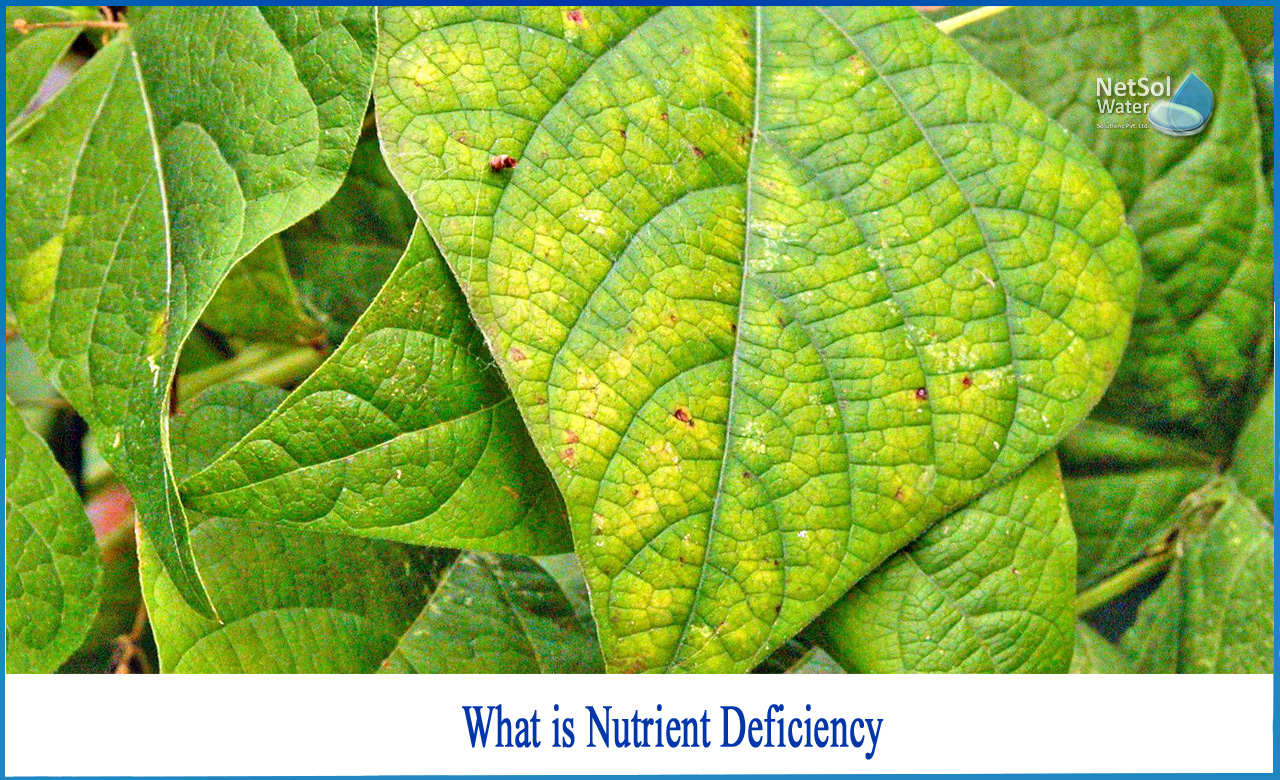

What is Nutrient Deficiency?

Nutrient shortage, or a lack of ammonia and phosphorus, can hinder an industrial wastewater lagoon from effectively eliminating BOD. While municipal lagoons frequently fail to fulfil ammonia and phosphorus limitations, industrial facilities may have the reverse issue: a lack of nutrients to treat BOD.

A balance of components is required for biological wastewater treatment: carbon (BOD), nitrogen (as ammonia—NH3), and phosphorus (as phosphate—PO4).

The proportion should be as follows:

1 component phosphorus, 5 parts nitrogen, 100 parts BOD

In contrast to municipal wastewater, which is typically regular, industrial wastewater can vary greatly and be quite unique. Depending on what's being produced, the components of industrial wastewater vary from factory to factory, or even within the same facility. Cleaning chemicals (which can skew pH) and drastically varying flows and loadings make industrial wastewater treatment difficult.

How can you tell whether your industrial treatment system is lacking in nutrients?

First and foremost, are you fulfilling your therapy objectives?

Undertreating wastewater in an industrial lagoon can result in penalties, production interruption, and odour complaints. Hydraulic short circuiting and inadequate aeration are the most typical reasons of poor lagoon performance, not nutrient lack, hence the first step is to assess those factors.

Is there a risk of short-circuiting?

A typical reason of poor performance is short circuiting, which occurs when wastewater flows through the lagoon without enough time to settle.

Do you have adequate aeration and mixing, as well as enough DO?

The wastewater treatment lagoon's lifeblood is dissolved oxygen. Aeration ensures that the bacteria have enough DO to eat BOD, and mixing guarantees that the oxygen, bugs, and waste are always in touch.

Urea treatment_ an emerging technology

Urea Treatment can be used on faecal sludge, blackwater, or urine and faeces that have been separated at the source. Urea, having the chemical formula CO(NH2), is used as an addition to assist sanitize sludge by creating an alkaline environment in the sludge storage devices.

When urea is introduced to faecal sludge, the enzyme urease, which is found in faeces, catalysis the decomposition of urea into ammonia and carbonate. The alkaline pH (above 7) caused by urea breakdown, affects the balance between ammonia and ammonium, favoringthe creation of ammonia. The primary sanitizing agent is unionized ammonia (NH3). Several species of germs, bacteria, viruses, and parasites have been shown to be inactivated by uncharged ammonia.

Ammonia disinfection has been demonstrated to be successful in urine, sewage sludge, and compost, although it is still in the research phase for faecal sludge. The temperature and partial pressures of ammonia gas above the liquid determine the process. As a result, process conditions are influenced by ventilation and head space. To reduce the quantity of ammonia gas that escapes and drives the balance towards soluble ammonia, treatment should be carried out in a sealed vessel. To maintain uniform sanitization in the sludge, the treatment should be done in batches.

Applicability of Urea

Urea treatment is a relatively new therapy that has yet to be generally adopted in emergency situations. However, first pilot projects and research are encouraging, and mounting data shows that Urea Therapeutic may be a viable treatment option for the acute emergency phase, given its short treatment period (about one week), easy technique, and use of widely available ingredients.

Urea in aeration tanks

The wastewater will be degraded by activated sludge in the aeration tank, lowering the BOD and COD contents.

For appropriate bacterial development, urea and DAP will be fed to the aeration tank in calculated amounts every day.

In the aeration tank, a steady feed rate will be maintained. A sludge percentage of 25 to 30 percent by volume will be maintained. To guarantee active microorganism development, the MLSS and MLVSS ratios will be maintained. The dissolved oxygen level shall be kept between 0.5 and 2.0 mg/lt. The aeration tank's overflow will be sent to the secondary settling tank for biomass separation.

If you are curious about more information on aeration and nutrient deficiency, then you can have an expert solution upon contacting Netsol Water, a leading manufacturer of Industrial and Commercial Water Treatment Plants and Wastewater Treatment Plants, among other services. Our treatment systems are very effective at removing all types of chemical, physical, and biological pollutants.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.