What is Microencapsulation?

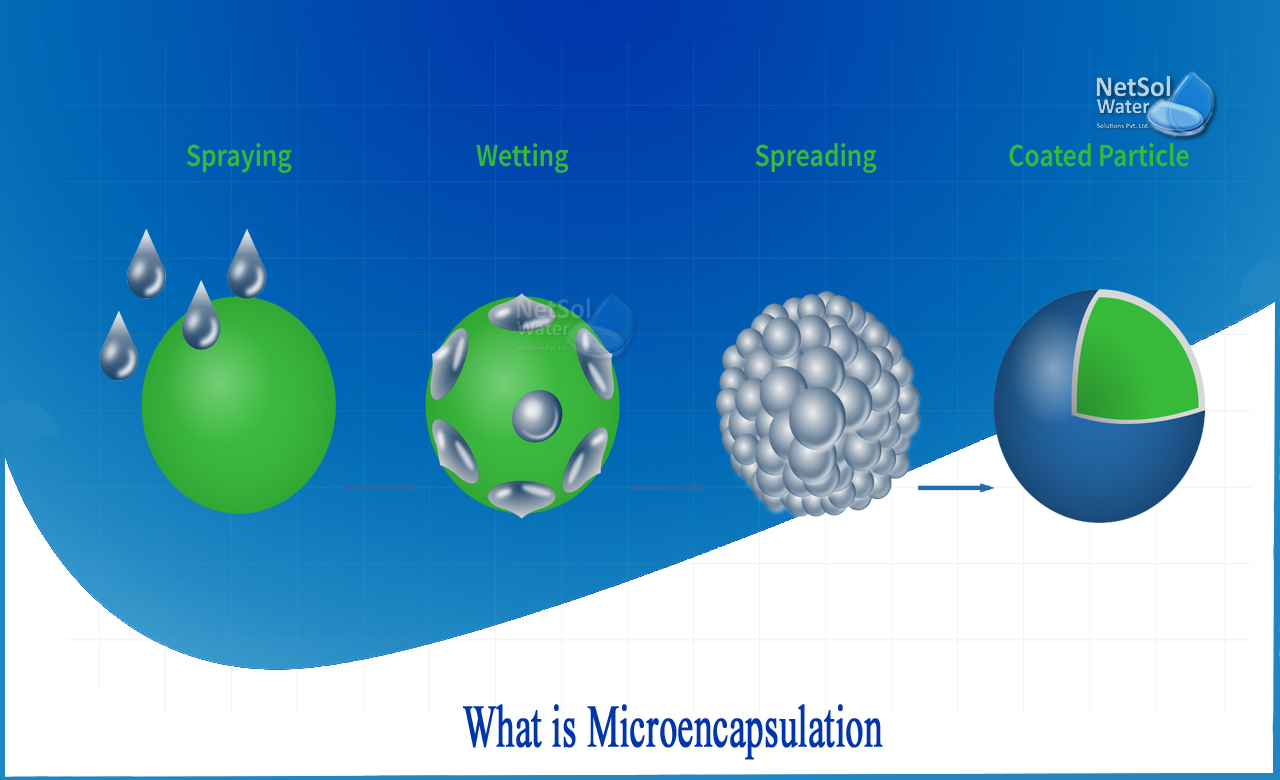

Microencapsulation is a process by which Individual active agent particles can be stored in a shell, encircled or coated with a continuous film of polymeric material to form particles in the micrometre to millimetre range, for protection and/or subsequent release.

This process involves encapsulating hazardous wastes that fit the RCRA definition of debris with a custom-tailored mixture of proprietary sealing agents, preventing contaminants from leaching or interacting chemically with the surrounding environment. This procedure is applicable to the majority of hazardous waste. For waste that can be entirely coated on all surfaces, including external and inside, microencapsulation is the preferable treatment.

There is a minimal likelihood that your hazardous waste will contact with outside elements because it is confined in the crystalline structure of the solidified matrix.

Microencapsulation in food sectors

Food producers and scientists throughout the world are working to find and classify foods that can be used as sources of beneficial nutrients to improve consumer health and well-being. According to this new paradigm, the development of new food items must integrate revolutionary technology with existing ways for controlling the bio-accessibility of certain food components. This method will become increasingly relevant as the relationships between health, diet, and genetics are elucidated.

In the food industry, the purpose of microencapsulation is to wrap an active chemical (core) with an encapsulating agent, also known as wall material that will isolate the active material protecting it from unfavourable alterations or hiding sensory qualities that are not appreciated by consumers. Under the application of a specified stimulus (e.g., pH or heat), the encapsulating material's isolation will break, releasing the active chemical in the exact target spot or under perfect conditions.

Microencapsulation processes

Microencapsulation is the science of encapsulating components (core or active) in a secondary substance (encapsulant, wall material, carrier, or cover) to produce small solid particles (1–500 m). These particles have the ability to discharge their contents at a set rate or under specific circumstances.

Making an emulsion from the active substance and the encapsulant material is the first stage in microencapsulation. One or two agents can be used to make the combination. The mixture is subsequently dried, resulting in microcapsules of various diameters and shapes, depending on the procedure and materials employed in the preparation. For microencapsulation, physicochemical methods (simple or complex coacervation, separation of organic phase, and liposomal wrapping) have been developed, as well as physical methods (spray-drying, spray chilling, spray coating, fluidized bed, centrifugation, extrusion, and co-crystallizatioion) and chemical methods are (interfacial polymerization and molecular inclusion).

Conclusion

Foods and other substances microencapsulated have a wide range of applications, including the preservation of various nutritional components, bacteria, enzymes, colours, and other compounds, as well as preserving food and other items from the most rigorous processing procedures.

Because of their stronger affinity with various types of materials to be encapsulated, a variety of materials can be utilised as encapsulants, the most popular of which are carbohydrates and some proteins. There are various physical, chemical, and physicochemical encapsulation processes, the most common of which being atomization, fluidized bed, and coacervation.

Despite its broad applicability, encapsulation has struggled to find a foothold in the food business due to its high cost. While the pharmaceutical and cosmetics industries frequently advocate for the employment of high-cost procedures, the food industry operates on tighter profit margins, resulting in reduced production.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.