What is Grit Removal?

Grit removal is the process of separating gravel, sand, and other mineral materials down to a diameter of 0.2 to 0.1 mm.

Why are Grit Chambers used?

Grit cham?bers are used to

(a) Protect downstream moving mechanical equipment from abrasion,

(b) Prevent heavy deposits from forming in the pipe line, and

(c) Limit the frequency of digester cleaning due to grit build-up.

The grit collected in the chamber must be removed, dewatered, cleansed, and transported to a disposal facility. Grit removal is done manually in some smaller plants, although it is normally done automatically in larger plants. Inclined screw or tube conveyors, chain and bucket elevators, clamshell buckets, and pumps are the four automated grit removal methods. Grit is carried horizontally through a trough or channel to a hopper, where it is subsequently lifted from the hopper to another place in a two-step grit removal procedure.

There are three types of grit chamber

1: Rectangular arrangement with horizontal flow;

2: Flowing horizontally in a square arrangement;

3: Aerated

Further, based on a variety of parameters such as the quantity and quality of grit to be handled, head loss, terrain, and economic considerations for both capital and operational expenses, the following categories are created:

1. Mechanically Cleaned

2. Manually Cleaned.

Mechanization may be uneconomical in extremely small plants. Mechanized grit removal machines are ideal for sewage treatment plant flows above 10 MLD.

What is method of de gritting?

The grit chambers function as a sedimentation tank, separating the heavier inorganic materials (specific gravity around 2.65) and passing the lighter organic materials onwards. In the chamber, differential sedimentation and differential scouring velocity are maintained such that the flow velocity is not too low to produce the settling of lighter organic matter, nor too high to cause the settling of silt and grit contained in the sewage.

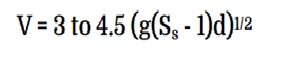

The scouring velocity of grit particles should always be smaller than the critical velocity of flow 'vc' beyond which particles of a specific size and density once settled.

Shield’s formula determines the critical scour velocity-

At peak flows, a horizontal flow velocity of 15 to 30 cm/sec is employed. This velocity must be maintained during any flow variation to ensure that only organic materials, not grit, are scoured from the bottom.

Cleansing of Grit

Grit is normally cleansed once it has been removed from the chamber, unless it contains a significant amount of organic materials that has an unpleasant odour. They are mostly dumped or disposed of in a sanitary landfill. The method of disposal is chosen based on the physical and chemical properties of the grit, its quality, and the availability of disposal site, among other factors.

Feel free to contact Netsol Water with any queries you may have about custom-designing and manufacturing water or wastewater treatment systems. Contact us at +91 9650608473 or contact via email at enquiry@netsolwater.com for additional information.

You may also schedule a conversation with an engineer or obtain an estimate by visiting our website. We can guide you through the process of determining the best solution and realistic pricing for your wastewater treatment system requirements.