What is Dissolved Oxygen supplementation?

The use of hydrogen peroxide to boost the concentration of dissolved oxygen (DO) in an aerobic bioreactor is known as "DO supplementation”. Because chemically raising DO is more expensive than mechanically increasing DO, employing peroxide is rarely a first choice. However, if your aeration blowers are out of commission due to equipment failure and your DO has gone below 2.0 mg/L, affecting nitrification or BOD/COD removal, hydrogen peroxide can be used to restore bioreactor oxygen levels, BOD removal, and nitrification.

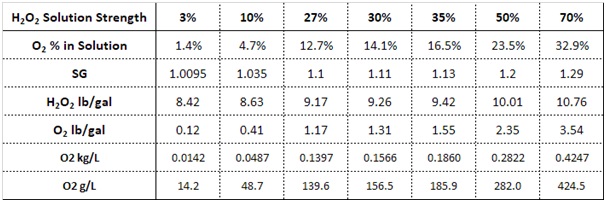

The main technical questions from those unfamiliar with the use of hydrogen peroxide revolve around how much oxygen is actually transferred to the mixed liquor suspended solids (MLSS), or more specifically, the biomass, from a gallon or litre of hydrogen peroxide, and how many gallons or liters will it take to raise the DO concentration in the bioreactor to >2.0 mg/L.

Only an estimate of the amount of hydrogen peroxide necessary to raise the DO concentration from its current level to a higher one can be made.

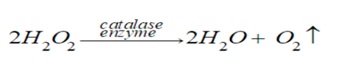

Hydrogen Peroxide Decomposition

As indicated in the chemical equation below, hydrogen peroxide decomposes into water and oxygen.

In an active sludge system, bacteria release catalase enzyme in the presence of hydrogen peroxide, which quickly converts the hydrogen peroxide to water and oxygen, as seen below.

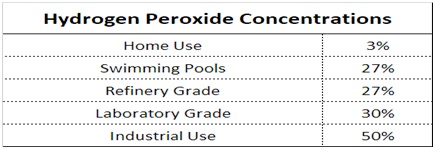

Hydrogen Peroxide Concentration

Hydrogen peroxide is available in variety of concentrations. Below is a list of the most frequent concentrations.

The greater the concentration of hydrogen peroxide in industrial applications, the more cost-effective it becomes because less water is carried. Because of hydrogen peroxide's strong oxidising potential, handling and storage needs become more of a worry as the concentration grows.

The oxygen contribution from hydrogen peroxide is summarized in the table below at a variety of concentrations.

Conclusion

Those who need to supplement (raise) their bioreactor's dissolved oxygen (DO), want to know how much hydrogen peroxide they'll need. It would be good if there was a way to give a straightforward answer, but there isn't.

We can compute how many pounds or kilos of oxygen we are supplying to a bioreactor based on the volume and concentration of hydrogen peroxide using the calculations we made before. However, such knowledge cannot be used to determine how much the dissolved oxygen concentration in the bioreactor will rise. Organic loading, wastewater temperature, pH, MLSS content, and other parameters all have a role. As a result, the best that can be done is to estimate the oxygen use.

How can Netsol help!

Netsol Water collaborate with a wide range of international organizations to tackle complicated wastewater problems by strategically integrating modern treatment technology with practical solutions.

For any assistance, inquiry, or product-purchase-related questions, call on +91-9650608473 or email at enquiry@netsolwater.com