What is BioFOR technology?

BioFOR filters are biological reactors with an aerobic or anoxic process that use suspended growth technology for municipal or industrial wastewater treatment.

In secondary and tertiary treatment, the BioFOR method is typically utilised to remove BOD, TSS, and ammonia pollutants. Because of the filtering activity of the Bio filter medium, BioFOR units release treated water that meets high quality criteria for all parameters.

BioFOR units can handle higher filtration velocities because they are designed to manage heavier organic loadings than traditional systems. The devices combine soluble pollutant treatment and solids separation in a single compact reactor, eliminating the need for secondary clarifiers. The filter operation is automated via a PLC-based control system.

How does BioFOR work?

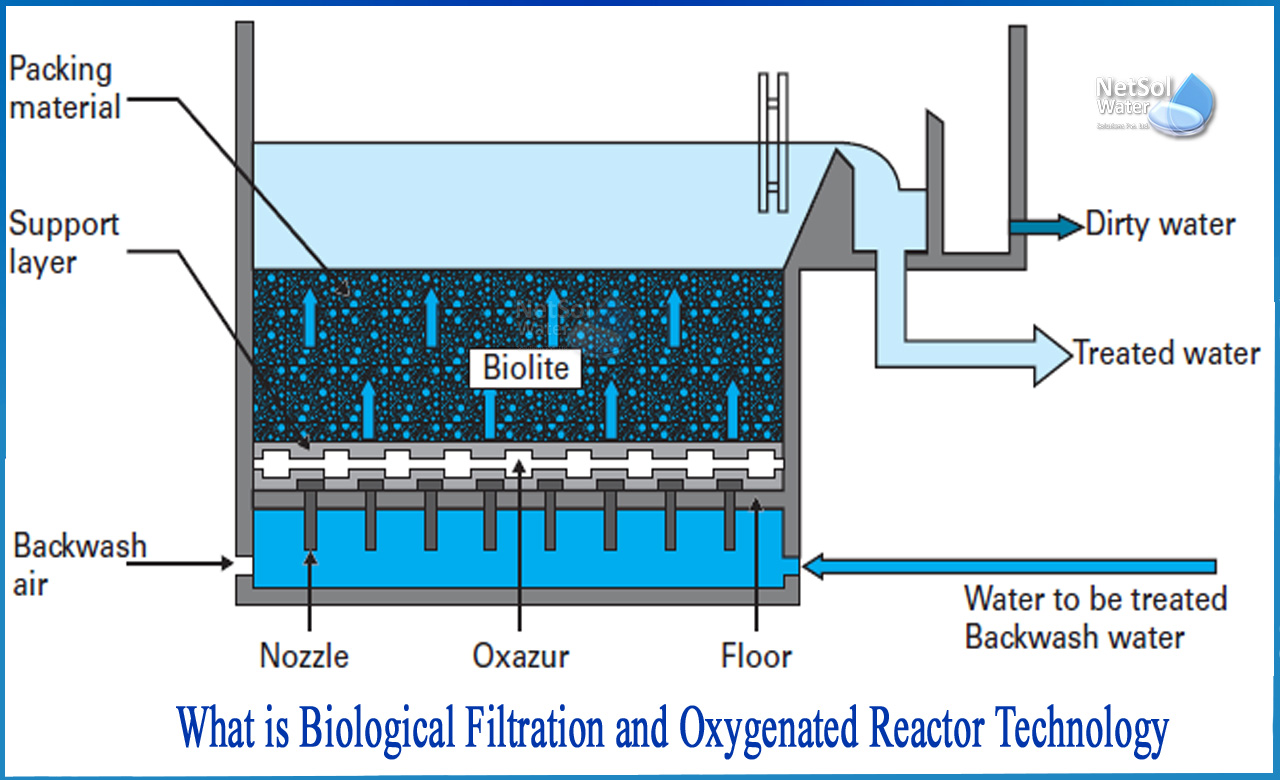

The effluent to be treated enters constantly from the bottom of the reactor, and the nozzle underdrain, distributes it evenly throughout the entire filter surface area. The water is subsequently filtered using Bio-medium, which traps the suspended particles. The high concentration of fixed-film biomass that is kept on the filter media during the filtration cycle eliminates carbonaceous and nitrogenous pollutants.

Air diffusers continuously feed air into the lowest section of the reactor in the aerated variants (for BOD removal and nitrification).

Since the treated water is at the surface of the filter in contact with the atmosphere and the untreated water enters at the bottom, the adoption of a co-current up-flow design helps to prevent odour formation.The quantity of filters in the filtration operation is determined by the amount of water that enters the facility. Off-duty filters are aerated on a regular basis during low flow periods to keep the biomass in good shape. Operating costs (due to process air output) can be decreased because filters can be taken out of service when not in use.

Important features of BioFOR

-Up-flow filtration, wherein feedwater stretches the filter media, resulting in an equitable distribution of biomass throughout the bed;

-Co-current feedwater and air flow, which eliminates short circuiting and extends filter run periods;

-Quick response to changes in flow and load exclusive nozzle floor design that ensures optimal fluid distribution throughout filtration and wash operations.

-Washing system that can handle filter bed depths of up to 13 feet (4.0 m)

Applications of BioFor

-BioFOR for BOD, COD, and TSS elimination

-BioFOR N for ammonia nitrogen nitrification

-BioFOR C+N for BOD elimination and nitrification at the same time

-BioFOR pre-DN for nitrate elimination without extra carbon source as a pre-denitrification phase

-BioFOR post-DN for nitrate elimination as a final denitrification stage with carbon addition

Specific requirements for BioFOR Technology

•Polyelectrolyte for high rate sedimentation in tube settlers with the addition of alum as a coagulant

•Special clay-based granular filter material known as 'biolite.'

•Wastewater recycling and backwashing of the BioFOR bed

•STPs do not provide treatment (digestion) or disposal of clarifier sludge because to space constraints.

Advantages of BioFOR Technology

- Higher aeration efficiency with co-current diffused aeration system

- Space savings as secondary sedimentation is dispensed

- Compact layout as a result of increased rate processes

- Able to tolerate flow rate and organic load changes

- Adherence to tougher discharge regulations

- Effluent that is acceptable for industrial use

- Effluent that can be disinfected with ultraviolet light without filtration

- Absence of aerosols and odours in the work environment

- No corrosive gases in the vicinity

- Less staff is required due to minimal operation oversight.

Conclusion

As an alternative to standard aerobic treatment technologies, BIOFOR technology is being employed as an enhanced aerobic approach for sewage treatment. When compared to alternative treatment technologies, BIOFOR requires the least amount of space.

The system was found to be quite effective in removing Faecal Coliform from wastewater, but not so much at removing Total Coliform. However, disinfection can result in a high-quality bacteria population reduction. As a result, BIOFOR systems expand India's options for a more cost-effective and secure sewage treatment procedure.

Netsol Water is India's leading manufacturer of all sorts of water treatment facilities; as a result, Netsol can adapt and deliver BIOFOR technology to meet the needs of customers.