What are the different types of sedimentation tanks?

Sedimentation tanks are classified based on a variety of variables-

1. On the basis of operating techniques

a. A fill-and-draw tank

b. Continuous flow type tank

2. On the basis of shape

a. A circular tank

b. A rectangular tank

c. A tank with a hopper bottom

3. Based on location

a. Primary tank

b. Secondary tank

A: On the basis of operating techniques_

1: Fill and draw type sedimentation tanks

Water from the intake is kept for a period of time in a fill and draw sedimentation tank. It's possible that the time is 24 hours. During this period, the dispersed particles sink to the tank's bottom. The water is drained out of the outlet after 24 hours. The particles that have settled, are then removed. This procedure takes 6 to 12 hours to complete. In the case of a fill and draw type sedimentation tank, one complete sedimentation activity takes 30-40 hours.

2: Sedimentation Tank with Continuous Flow

Water is not permitted to rest in this scenario. Flow occurs at all times, although at a relatively slow rate. Suspended particles settle to the bottom of the tank during this flow. It is possible for the flow to be in either a horizontal or vertical direction.

-Sedimentation tank with horizontal flow

The tanks are usually rectangular in design. They are twice as long as they are wide. Because they must travel a greater distance to settle all suspended particles, they must flow at a faster rate. In this scenario, the maximum allowable velocity is 0.3m/sec.

-Sedimentation tank with vertical flow

The vertical flow type sedimentation tanks are normally circular in form, with the flow moving vertically. To dispose of the collected sludge, a hopper bottom is supplied at the tank's bottom.

B: Types of Sedimentation Tanks depending on Shape-

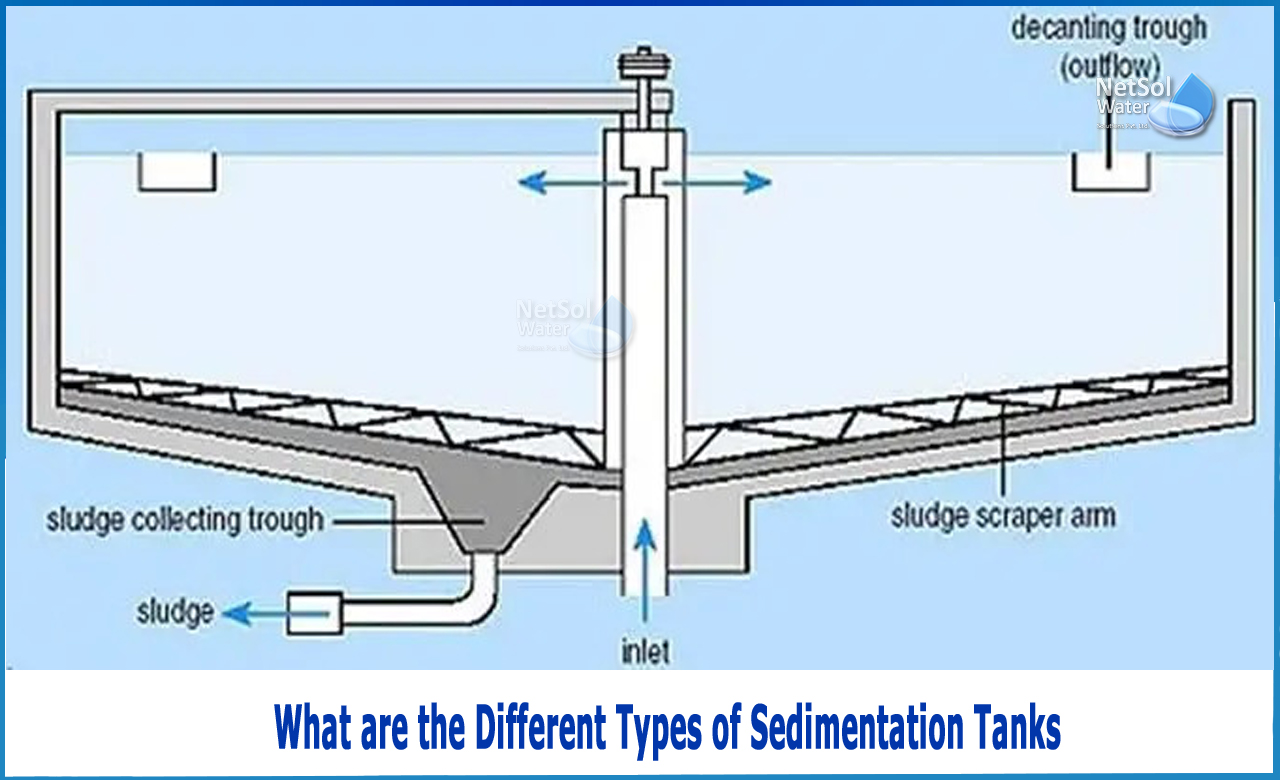

1: Circular Tank

For continuous vertical flow sedimentation tanks, circular sedimentation tanks are preferable. In this scenario, the influent is routed through the tank's centre pipe, resulting in radial flow. Mechanical sludge scrappers are used to gather the sludge, which is then sent to the bottom via a sludge pipe. However, circular tanks are more expensive than rectangular tanks, but they have a higher clarity efficiency.

2: Tank with Rectangular Shape

Rectangular sedimentation tanks are the most common and commonly utilized sedimentation tanks. In rectangular tanks, the flow occurs in a horizontal, lengthwise direction. For rectangular tanks, baffle walls are sometimes used to avoid short circuiting. Rectangular sedimentation tanks provide reduced maintenance expenses. They can also be used in large-scale plants.

3: Bottom Hopper Tank

A deflector box is situated at the top of the hopper bottom tank, which deflects the influent coming from the central pipe downwards. Sludge collects at the bottom and is pumped out using a sludge pump.

C: Sedimentation Tank types depending on Location

1: Tank for Primary Sedimentation

The primary sedimentation tank is a standard sedimentation tank in which water is held at rest for a period of time and sludge and oily debris gathered at the bottom and top are removed. The wastewater is released into an aerobic filter after the main sedimentation process, where the activated sludge process takes place.

2: Tank for Secondary Sedimentation

Following the activated sludge process, the wastewater passes through a secondary sedimentation tank, where suspended particles containing bacteria are collected and reflected towards the aerobic filter to maintain a high microbe concentration.

What can we offer?

If you are curious about the sedimentation process and want to know more, then we can provide a platform for your doubts to settle.

Netsol Water can also help you with design calculations, budgetary expenses, preliminary layouts, and a lifetime cost analysis for any water or wastewater related equipment.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.