What is RBC?

RBC is recognised as “rotating biological contactor”. In Rotating Biological Contactor, the settled sewage is transported through a trough containing a rotating media. This media provides a surface area for the formation of a Biological Film or biomass, which then oxidises the contaminants when it comes into touch with the settled sewage and oxygen (air).

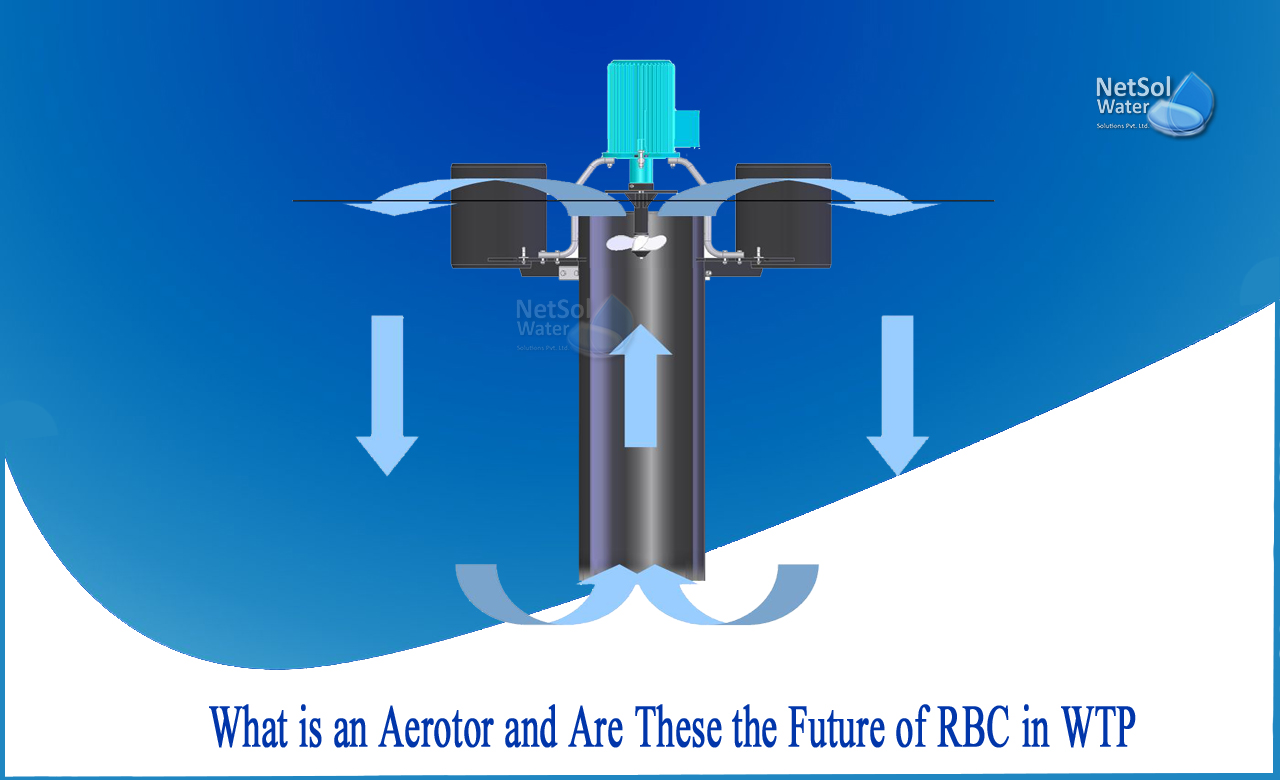

What is an aerotor and Are these the future of RBC in WTP?

The Aerotor is a next-generation RBC that combines a fixed film reactor and an active aeration system on a horizontal shaft that covers 97% of the drum's surface area. The spiral-shaped rotatable GRP medium is enclosed in an outer drum to offer active aeration, a large surface area, and net hydraulic lift.

The Aerotor is a plug flow system that can handle both high and low loads without difficulty. It offers all of the benefits of classic RBCs, such as low power, maintenance, spare parts, and operator input, but none of the drawbacks, such as one-sided growth on shut down, excess biofilm growth, and flow bypass at low and high flows. The Aerotor is a totally portable and relocatable sewage treatment plant that may be installed above or below ground without the need for a concrete surround.

The Aerotor is intended for use with in-situ or prefabricated primary and final settling tankage to treat settled sewage. It's frequently used to augment existing sewage treatment plants that are underperforming or overburdened, or for Ammonia Removal (Nitrification), where it may achieve ammonia levels of less than 1 mg/l. The Aerotor is a complete plug-and-play system that may be put above or below ground without the need for a concrete surround. It also produces 350 mm of net hydraulic lift from intake to outlet, allowing it to be installed with minimal pipework alterations.

Applications of aerotor

- existing communal septic tank upgrades

- chronically or seasonally overburdened works

- tertiary treatment, such as nitrification

- phased construction with modular units

- in-situ constructed work

Advantages of aerotor

· Plug Flow

· Active Aeration

· Net Hydraulic Lift from inlet to outlet

· Next Generation RBC

· 3 x more efficient

· Very low operator/power/spare parts cost

· Does not require concrete surround

- cheap operating costs

- temporary or permanent

- prefabricated "ready to go"

· compact

How does aerotor works?

The Aerotor catches atmospheric air with each spin, draws it down into mixed liquid in a steel or concrete basin, and then gently releases it as course bubble aeration. Additional cascade aeration raises the dissolved oxygen in the upper layer of the basin during the rotation. A thoroughly mixed system is ensured by the combination of the aerotor's slow rotation, powerful air release, and the inclusion of a peripheral mixing paddle.

In addition, the aerotor has a vast surface area for the growth of fixed films. The particular polypropylene discs' inner and exterior give the ideal environment for a range of associated growing organisms. To avoid discharge violations during peak or diurnal oscillations, these organisms will react promptly to an increased food source, or shock load.

A variable speed drive linked to the rotor can vary the amount of aeration by causing it to rotate faster or slower depending on the real oxygen demand. The Aerotor is a compact biological treatment device that combines activated sludge and fixed film in a low-power input. The Aerotor's one-of-a-kind medium serves as both a fixed film surface area and a vehicle for coarse bubble aeration. The Aerotor's design eliminates the need for diffusers, air piping, control valves, diffused aeration blowers, or extra mixers, allowing for effective aeration.

Conclusion

The Aerotor has a proven track record, having been deployed in more than 40 nations throughout the world for more than 30 years in all types of temperatures. Many wastewater treatment companies provide this market-leading package sewage treatment. Many criteria influence the best unit for a specific application, including influent strength, design flow, existing equipment, and the desired final effluent quality.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.