How to Efficient waste to energy conversion processes for ETP?

Waste-to-energy is an important technology that can assist businesses in becoming more sustainable not only by reducing waste volume, but also by producing gas that can be reused at the plant or used to generate electricity, which can offset operational costs and even be sold back to the grid. While these incentives are substantial, implementing waste-to-energy does not address all environmental issues and, unfortunately, introduces new challenges.

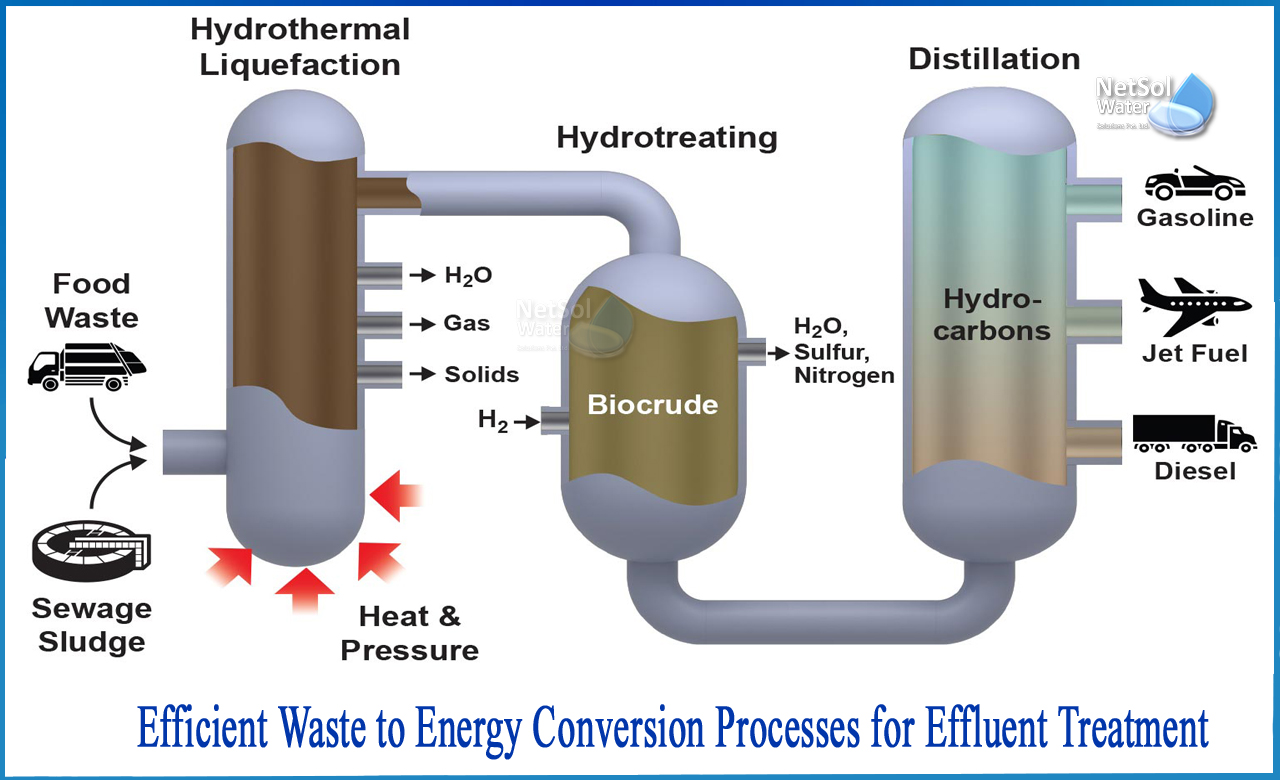

Waste-to-energy technology, such as anaerobic digestion, is used in a variety of industries to extract biogas — a mixture of methane and carbon dioxide — from organic wastes. Digestate, a by-product of anaerobic digestion, is a stable fermented waste that is frequently used as a fertilizer.

Organic waste from food and beverage processing is ideal for waste-to-energy treatment. Process wastewater, whey, primary sludge from wastewater pretreatment, and manure, among other biosolids, can all be found in waste streams.

The challenges of Waste-to-Energy Technology

The high concentration of hydrogen sulphide in the produced biogas, as well as the nitrogen content in the digestate, is one of the most critical issues confronting waste-to-energy treatment.

Excess Nitrogen Treatment in the Digestate

An additional challenge is the high nitrogen content that is frequently found in digestate. When digestate is applied to farmlands, the nitrogen can cause environmental problems, especially on runoff-prone land.

Nitrogen can be found in both solid and liquid form in food and beverage waste streams. It can also be found in compounds like struvite or in solutions as ammonium bicarbonate.

Efficient, Long-Term Solutions for Tough Waste Streams

Waste-to-energy treatment and biogas production, when combined with other technologies, can be very cost-effective and environmentally friendly while also creating new revenue opportunities, even for difficult-to-treat waste streams such as those from slaughterhouses.

Because effluents differ so greatly from one facility to the next, there is no standard solution for the treatment of wastewater from the food and beverage industries; instead, a custom configuration is required.

Slaughterhouse Waste Treatment

Wastewater is first treated with dissolved air flotation (DAF), which removes up to 80% of the organic load and 65% of the nitrogen load. After that, the sludge is treated with an anaerobic digestion process capable of treating effluent streams with extremely high nitrogen concentrations.

When the anaerobic digestion process is finished, the solid and liquid digestate are separated. The solids, which account for approximately 20% of the incoming waste, can be used as fertilizer, while the liquid is sent to a wastewater treatment plant along with the clarified water from the dissolved air flotation stage.

A two-stage nitrification-denitrification process is used to reduce the chemical oxygen demand to less than 100 mg/L and the total nitrogen level to less than 20 mg/L. The operational costs can be reduced further if the system is equipped with a pre-treatment system.

How can we help?

Netsol Water is a significant water and wastewater treatment firm in India, offering WTP, WWTP, STP, ETP and RO Plant manufacture, among other services. We are committed to providing our valued customers with hands-on service, expert counselling, and training. Every environmental problem and its management have a solution in us.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.