Overview

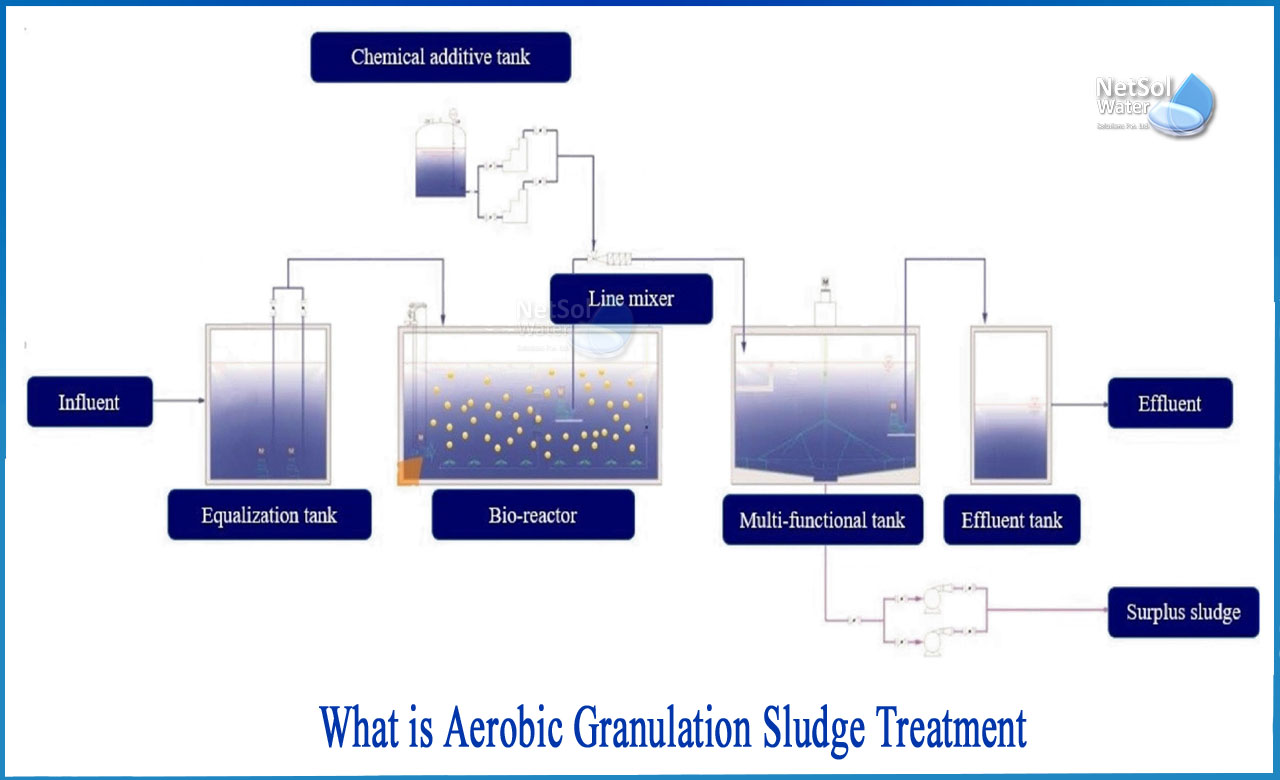

Aerobic granular sludge (AGS) was designed to be a superior substitute for activated sludge (AS) in the biological treatment of municipal and industrial wastewaters, as well as to overcome sludge–water separation difficulties.

AGS is composed of dense self-immobilized microbial granules that have a compact microbial structure, a high biopolymer content, and rapid settling velocities. Granular microbial growth allows for improved biomass-water separation, higher biomass concentrations in the bioreactor, and simultaneous nitrification, denitrification, and phosphate removal from wastewater in a single treatment tank.

What is aerobic granulation sludge treatment?

Conventional activated sludge systems are frequently used in sewage treatment plants to treat wastewater biologically. Due to the sludge's poor settling qualities, these systems often need vast surface areas for treatment and biomass separation units. Aerobic granules are a kind of sludge that may capture flocs and microorganisms on their own to create spherical and sturdy compact structures.

Aerobic granular sludge has great settleability, high biomass retention, simultaneous nutrient removal, and toxicity tolerance. Aerobic granular sludge is typically cultured in SBR (sequencing batch reactor) and effectively used as a wastewater treatment for high strength wastewater, hazardous wastewater, and household wastewater. In comparison to traditional aerobic granular COD removal procedures, current research focuses on simultaneous nutrient removal, namely COD, phosphorus, and nitrogen, under pressure circumstances such as high salinity or thermophilic environments.

New technologies have been developed in recent years to increase settleability. One of them is the use of aerobic granular sludge technology.

The Advantages of the AGS Process

As a result, as compared to the standard AS process, the AGS process reduces the land footprint (50–75 percent lower) and energy (30–48 percent lower) of wastewater treatment facilities (WWTPs). Over the previous two decades, the AGS process has evolved from a laboratory-scale to a full-scale WWTP solution.

Other advantages of the AGS method include lesser sludge output and resource use of extra sludge. The presence of prevalent microbial groups and their distinct metabolism helps to decreased sludge generation in the AGS process. Extraction of alginate-like exopolymer improves resource recovery and helps with sludge control. Nonetheless, the long start-up times for AGS creation and disintegration are viewed as barriers to wider use of AGS technology.

Granules' Stability

The operational characteristics of the bioreactor, such as anaerobic feeding, a feast-famine regime, and short settling times, force the selection of slow-growing bacteria with distinct metabolic properties and promote granulation. Anaerobic feeding and sludge removal procedures are critical for granule stability.

Aerobic Granular Sludge Characterization

1: Regular form: Granular sludge is characterized as a biofilm with a high degree of sphericity and a smooth surface as a result of the hydrodynamic pressure produced by the bioreactor's circular and continuous motion. As with previous biofilm technologies, the spherical shape is created without the presence of any supportive material to promote development.

2: Excellent settleability: AGS has a major advantage over CAS in terms of settleability.It is critical to separate the liquid phase from the solid fraction in wastewater treatment facilities (WWTPs) equipped with CAS systems.

3: Dense Structure: As noted in the preceding paragraph, dense and compact granules are preferred due to their outstanding settleability. This structure, however, is also crucial in conferring one of the most fundamental characteristics and advantages of granular sludge: the thick layers support the creation of many micro niches, which are driven by mass transfer behaviours from the outer layers to the inside layers.

Conclusion

Longer hydraulic and sludge retention durations, more time to treat and recycle sludge, and a bigger surface area are all required for conventional technology to be used. As a result of these factors, AGS has grown in popularity within the scientific and technical sectors.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.