Introduction to Reverse Osmosis (RO)

The process of propelling a solvent through a membrane from a location or region of high solute concentration to a region of low solute concentrationis known as reverse osmosis.The membrane in this case is semipermeable. This means that it enables solvent to pass through but not solute.

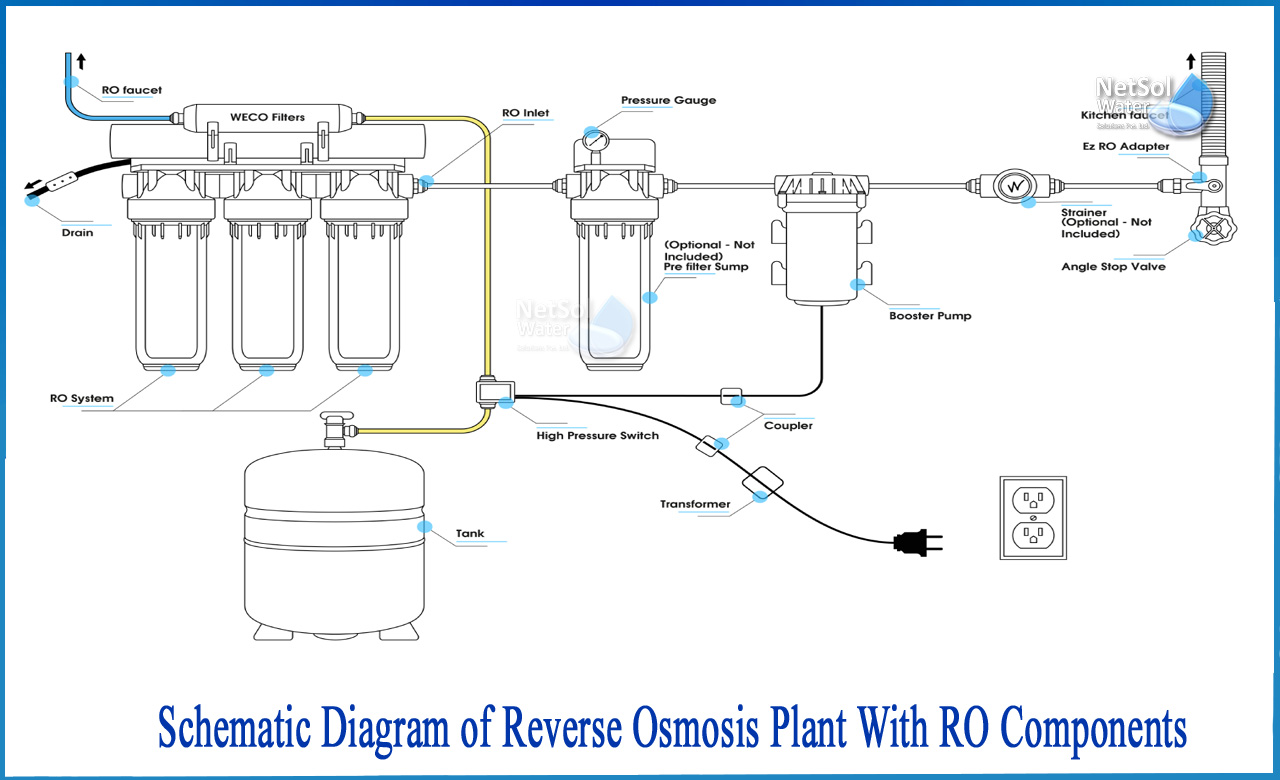

What is Schematic diagram of RO Plant with RO Components?

The separation takes place in a dense polymer barrier layer in reverse osmosis membranes. Because Reverse Osmosis does not occur naturally, it must be created by applying pressure to high-solids water to force it through the membrane, with pressures ranging from 8 to 14 bar for fresh and brackish water, and 40 to 70 bar for seawater, which has a natural osmotic pressure of around 24 bar (350 psi) that must be overcome.

Netsol RO Plant is made of one or more of the following components-

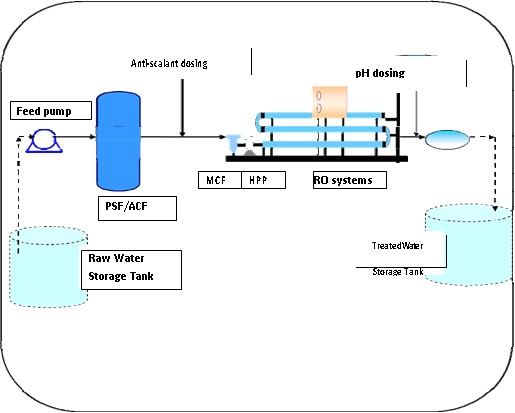

1: Raw Water Storage Tank: It is used to store water that has not been treated to remove minerals, ions, or particles.

2: Feed pump:The RO Feed Pump is created and developed in accordance with national market trends and with the specific needs of customers in mind. The body is made of steel. It is simple to set up.

3: Pressure Sand Filter (PSF): Prior to feeding the RO Plant, raw water is purified by a succession of filtering units. Suspended matter and turbidity are removed from raw water using a Pressure Sand Filter machine.

4: Activated Carbon Filter (ACF):Basic natural water may have varying amounts of colour, odour, chlorine, and organics, all of which are unsuitable for potable use and must be removed from the water. While passing water through the Carbon Bed, the Activated Carbon Filter eliminates chlorine, odour, and colour, pesticides, organics, and inorganic impurities.

5: Anti-scalant dosing:If the quantity of calcium and magnesium salts exceeds their solubility limit, they are likely to precipitate, causing membrane defects and scaling, which leads to poor treated water quality from the RO system. Antiscalant dosage (scale inhibitor) dosing mechanism is supplied to prevent this.

6:Micron cartridge filter (MCF):These filters with 10 µ, 20 µ, 5 µ, 1 µ, 0.45 µ, and 0.2 µ cartridges has a series of filtration. This is a consumable cartridge that should be replaced after a certain number of days of use. This is for added product water safety, since it passes through a number of filters and there is a potential of particle slippage, which may be prevented by using the cartridges.

7: High-pressure pumps (HPP):The water flow pressure must be increased for the reverse osmosis process to work. A vertical multistage centrifugal high pressure pump made of stainless steel is provided for this purpose. Operating pressure for the R.O. system should be around 14-16 kg/cm2. These are equipped with stainless-steel discharge pipework and control valves.

8: High-Pressure Switch: This is used to trip the HPP if the feed pressure is too high.

9: Time Totalizer:It is used for counting the working hours of a high-pressure pump or a reverse osmosis system.

10: RO System:The principle of 'Osmosis' allows the Reverse Osmosis System to reject 97–99 percent of total dissolved solids. R.O. Module assembly is mounted on a Structural Skid in this system. On the skid, high-pressure FRP Pressure Vessels (Pressure Tubes) with spirally wrapped membrane parts in series are installed.

11: pH Dosing:pH and conductivity measurements are also used to ensure that the RO system runs smoothly.Some RO membranes are sensitive to feed water pH, and if the pH is outside the permitted range of 5 to 8, they might be destroyed.

Upstream of the membrane, a pH sensor can provide a feedback signal that can be used to manage the dosing of acidic or basic reagents to keep the pH within acceptable ranges.To determine whether the total dissolved solids are being filtered successfully, conductivity measurements are taken at both the intake and output of the RO unit.

The feed soften water in RO system is separated into two streams: Product and Reject water.

1: Water that has been treated and has a lower TDS content is referred to as product water.

2: Reject water is highly concentrated water that should be drained rather than utilized.

On the Panel, the following instruments are provided for the safe functioning of the system-

1: Feed & Reject Pressure Gauge: To show the R.O.System's respective pressures.

2: Feed & Reject Flow Indicator:To show the R.O.System's respective flow.

3: TDS meter: It is used to determine the total dissolved solids (TDS) in raw and treated water.

12: Treated Water Storage Tank:The treated water from the R.O. system is collected in a storage tank with the required capacity. The tank is equipped with stainless steel pipework, isolation valves, and a suitable level indicator.

Schematic Diagram of RO Plant

What can we offer?

Netsol Water provides complete turnkey Industrial & Commercial RO plants based on the needs of the customer. We work with renowned machinery manufacturers and have completed projects all across India.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.