What factors that affect the performance of Activated Carbon Filter?

Granular Activated Carbon (GAC) is widely used to remove organic and disinfectant residues in water supplies. This not only improves the taste and minimizes health hazards but also protects other water treatment systems such as reverse osmosis membranes and ion exchange resins from damage, from oxidation and organic contamination. Activated carbon is the preferred water treatment technology because of its versatility and the fact that it does not add anything harmful to the water being treated.

Most activated carbon is made from raw materials such as nut shells, wood, coal, and petroleum. The typical surface area of ??activated carbon is about 1,000 square meters (m2/g). However, the raw materials are different,so they produce different types of activated carbon with different hardness, density, pore and particle size, surface area, extractable material, ash content and pH value.

These differences in properties make certain carbons preferable to other carbons in a variety of applications. The two main mechanisms that activated carbon uses to remove pollutants from water are adsorption and catalytic reduction.

Organic substances are removed by adsorption and residual disinfectants are removed by catalytic reduction.

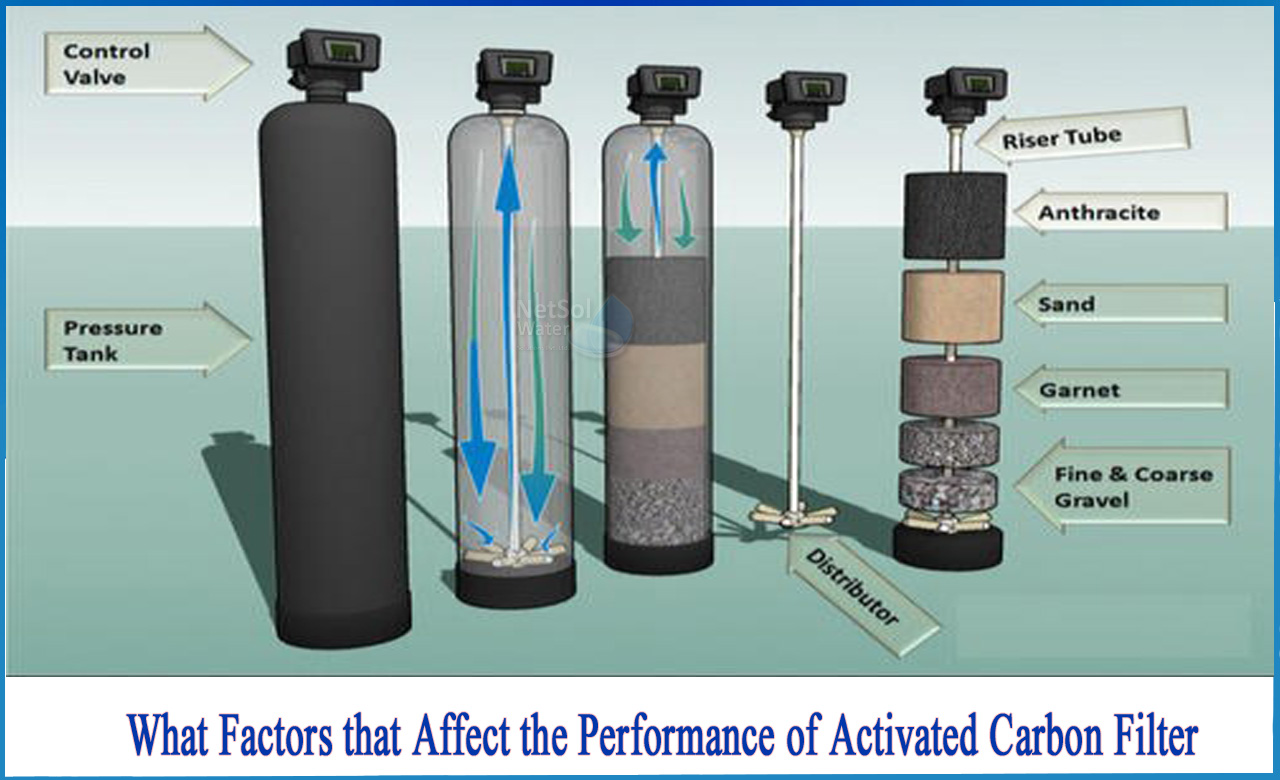

The factors that affect the performance of activated carbon are:

>Molecular Weight: As the molecular weight increases, the molecules are more soluble in water, which improves the adsorptivity of activated carbon. However, the carbon pore structure must be large enough for the molecule to move within it. To remove more difficult pollutants, it is necessary to design a mixture of high molecular weight molecules and low molecular weight molecules.

>pH value: Most organics are less soluble and are more easily adsorbed at lower pH. The higher the pH, the shorter the distance.

As a rule of thumb, increase the size of the carbon bed by 20 percent for every pH unit above neutral (7.0).

>Pollutant Concentration: The higher the pollutant concentration, the higher the ability to remove activated carbon. Contaminated molecules are more likely to diffuse and be adsorbed in the pores. However, the higher the concentration, the more wastewater leaks.

The upper limit of impurities is several hundred ppm. High concentrations of pollutants can increase contact time with activated carbon. In addition, the presence of hardness in the water improves the removal of organic matter, so, if possible, the activated carbon unit should be placed next to the ion removal unit. This is usually the case anyway. This is because activated carbon is often used in front of ion exchangers or membranes to remove chlorine.

>Particle size: Activated carbon is usually available in 8 x 30 mesh (maximum), 12 x 40 mesh (most common), and 20 x 50 mesh (minimum).

Finer meshes provide the best contact and removal, but with higher pressure drop. As a rule of thumb, the 8 x 30 mesh offers 2-3 times better distance than the 12 x 40 and 10-20-times better distance than the 8 x 30 mesh.

>Flow rate: In general, the lower the flow rate, the longer it will take for contaminants to diffuse into the pores and be adsorbed. Adsorption by activated charcoal is almost always improved with longer contact times.

A 20 x 50 mesh carbon bed can operate at twice the flow rate of a 12 x 40 mesh bed, and a 12 x 40 mesh carbon bed can operate at twice the flow rate of 8 x 30 mesh operation bed. If you are considering higher flow rates with finer coal than,be aware of the increased pressure drop.

>Temperature: Higher water temperatures can reduce the viscosity of the solution and increase the diffusion rate, thereby increasing adsorption. It depends on the organic compound being removed, but generally, lower temperatures seem to favour adsorption.

>Organic Removal: Organic material in public water supplies comes from dead and decaying plant life, which becomes more soluble in water over time and exists as large, highmolecular weight organic acids.Eventually, smaller molecular weight acids of varying sizes form.

Typical organic acid molecules range in molecular weight from a few hundred to tens of thousands. The size, number, and chemical structure of organic acid molecules are determined by the pH of water and temperature. Therefore, the number of organic acids is almost infinite. As a result, it is possible and difficult to remove organic matter as required by site. The adsorption properties of activated carbon are used to remove organic matter.

Generally, adsorption occurs because all molecules exert a force to attach to each other. Activated carbon adsorbs organic materials because the attractive force between the carbon surface and the impurities is stronger than the force that keeps the impurities dissolved in water.

Adsorption is weak and occurs only when organic molecules are close to the carbon surface. The large surface area of ??activated carbon allows adsorption due to its particle size and pore composition.

The performance of the activated carbon filter is improved by factors that reduce the solubility and increase the accessibility to the pores.

For more information on Activated Carbon Filters, contact Netsol water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.