What does MBR sludge cause?

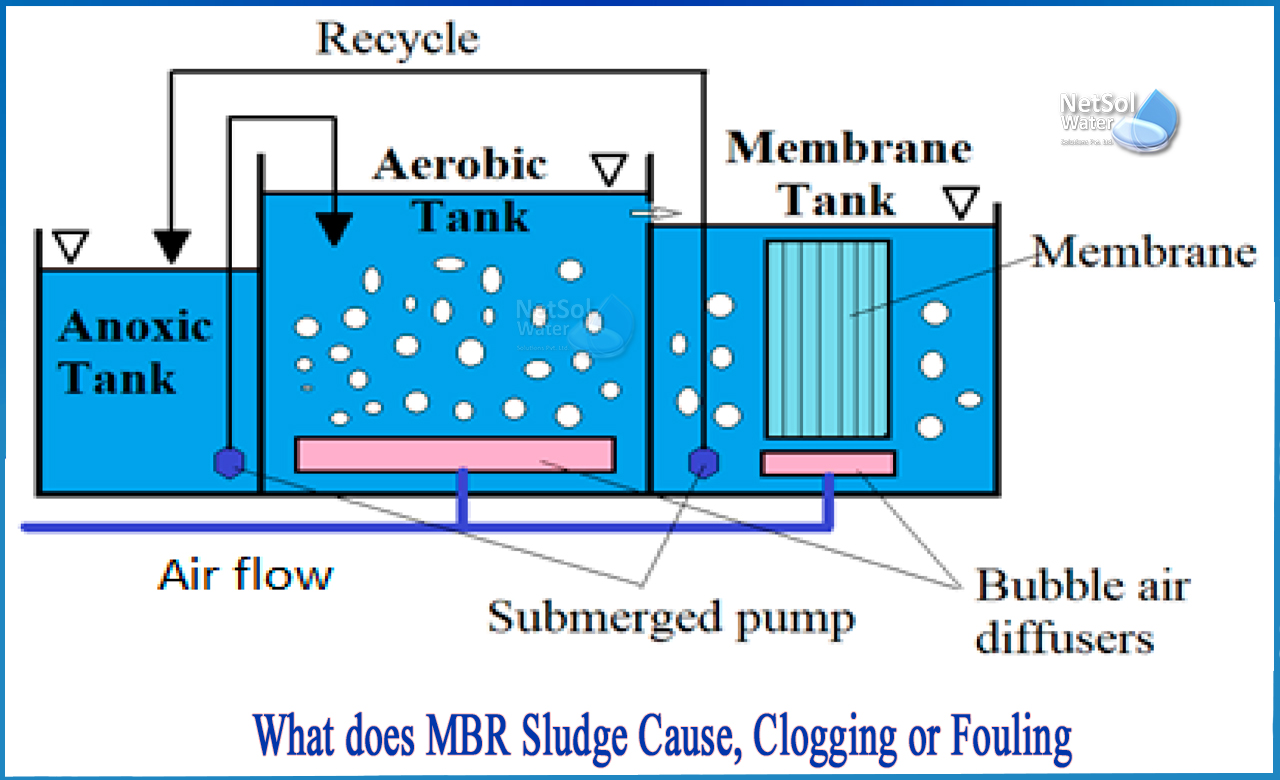

Membrane bioreactor (MBR) technology has emerged as the preferred wastewater treatment technology. MBR is, in fact, one of the most significant innovations in wastewater treatment, as it overcomes the drawbacks of traditional plants, such as large space requirements for secondary clarifiers, liquid–solid separation issues, excess sludge production, and limitations with recalcitrant removal. MBRs have been used for wastewater treatment and reclamation in both municipal and industrial settings.

An MBR combines a traditional biological treatment system with physical liquid–solid separation via membrane filtration into a single system. High-quality effluent, higher volumetric loading rates, shorter hydraulic retention times (HRT), longer solid retention times (SRT), less sludge production, and the potential for simultaneous nitrification/denitrification in long SRTs are all advantages of MBR technology over ASP.

The use of membranes eliminates the need for secondary clarifiers in the system. The removal of secondary clarifiers and the operation of MBR at a lower HRT result in significantly reduced plant area requirements. However, there are some drawbacks to using MBR technology, such as higher energy costs, the need to control membrane fouling issues, and the potential high costs of periodic membrane replacement.

Membrane fouling in MBR:

Membrane fouling is defined by the International Union of Pure and Applied Chemistry (IUPAC) Working Party on Membrane Nomenclatures as "the process resulting in loss of performance of a membrane due to the deposition of suspended or dissolved substances on its external surfaces, at its pore openings, or within its pores."

These foulants can be suspended particulates (microorganisms and cell debris), colloids, or solutes in the MLSS. Membrane fouling is caused by physicochemical interactions between foulants and membrane material. Failure to control membrane fouling in MBRs appropriately may result in failure to treat the required design flows in some cases.

Fouling in MBRs takes several forms, including pore narrowing, pore clogging, and cake formation. Foulants clogging membrane micropores is referred to as pore clogging. The size of the particle and the size of the membrane pore both play a role in pore clogging. Sticky substances in the solution aid in the attachment of materials in the pores. Cake formation, on the other hand, is caused by the continuous accumulation of bacteria clusters, biopolymers, and inorganic matter on the membrane, which forms a layer (bio cake). The cake layer strengthens the membrane's filtration resistance.

What is clogging?

The agglomeration of gross solids within or at the entrance to the membrane channels is referred to as clogging. Sludging is a term used to describe clogging within the channels.

Rags (or braids) formed from aggregated filamentous matter (specifically textile fibers such as cotton wool) in the feedwater can clog municipal wastewater treatment membranes. This is referred to as 'ragging' or 'braiding.' Sludging and ragging are the most common causes of unscheduled manual intervention in municipal MBRs.

Although it still appears to be a roughly inverse relationship between fouling and clogging. If the membrane channel is clogged with a highly fouling industrial sludge, fouling occurs. However, if there is a reasonable quality sludge with a relatively high sustainable flux, clogging (or, more specifically, sludging, the filling of the membrane channels with solids, sometimes referred to as 'localized dewatering') becomes apparent.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.