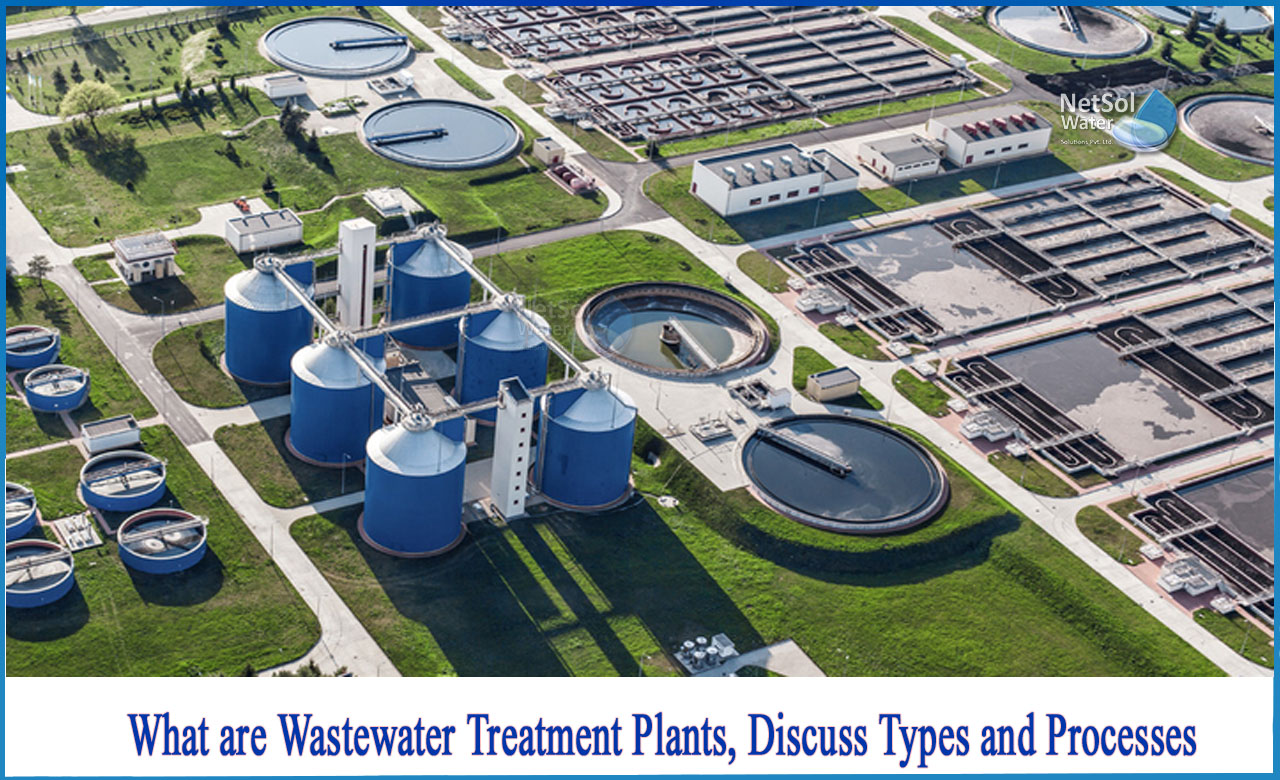

What are Wastewater treatment plants, Discuss types and processes?

There are several methods available for implementing different water treatment stages.

Physical methods for mechanical treatment are aeration, sedimentation and heat effects. This includes the use of filters and sieves. Biological processes such as anaerobic wastewater treatment, biochemical oxidation, or sludge digestion, chemical processes such as neutralization, disinfection, aggregation, and precipitation, membrane processes such as filtration, penetration and Nano filtration, etc. all are included.

Urban sewage treatment plants have the highest amount of wastewater treated, so more diverse combinations and more effective processes are needed here. The procedure you use depends on the type of wastewater treatment plant.

The treatment process can be divided into various stages:

Level 1: Mechanical water treatment

In the first stage, the still completely untreated wastewater is mechanically cleared of all large debris. This removes about 20-30% of the solids it contains. For this purpose, wastewater is supplied to a screening plant where a screen or sieve drum, filters coarse impurities such as leaves, paper and fibres. From a few centimetres of coarse sieve to a few millimetres of fine sieving, a variety of sieves with water flowing at different speedsfilterthe coarse material in stages. Machine-extracted debris is dehydrated and disposed of in an incinerator.

Pre-cleaned water reaches the so-called sand collector. Wastewater technology uses sand basins to remove coarse particles such as stones, glass shards, and sand, as well as coarse organic matter that has not been sifted. This occurs at a relatively high flow rate of about 0.3 m/s. A distinction is made between unventilated long sand collectors, ventilated long sand collectors (also known as cylinder sand collectors), and round sand collectors.

Primary purification equipment is the next stage of wastewater treatment. The sewage speed is about 1.5 cm/s, which is considerably slower than the sand collector. By expanding the basin, the flow velocity decreases. Low flow rates are required so that finer dirt particles can settle on the ground or water surface depending on their properties. The sludge generated during sedimentation (sedimentation to the bottom) is called primary sludge. It is usually composed of organic materials. The primary sludge is pushed from below through the scraper into a new sludge funnel. Floating material is transferred to the floating sludge channel. The pump carries fresh sludge to the so-called digestion tower.

In the digestion tower, methane gas is produced in four stages: hydrolysis, acidification, acetone and methanogens. It is converted to electricity at a block thermal power plant and can be used to power the system. The digestion process in the digestion tower is completed in about 4 weeks. What remains is odourless sludge, which is often used in agriculture after being dehydrated with a centrifuge or filter.

The mechanical cleaning phase ends here. At this stage, on average, 30-40% of the pollutants are removed from the wastewater. On the way through the sewage treatment plant, the wastewater is now reaching the next stage of wastewater treatment.

Level 2: Biological cleaning

In most sewage treatment facilities, water that has been pre-washed during the mechanical treatment stage is placed in so-called activated sludge tanks, which are often designed as circulation tanks. Biological cleaning is done here.

Water circulates with the help of oxygen and propellers. There are ventilated areas where different environmental conditions are created for bacteria and microbes. These microorganisms eat organic impurities that are still present in the water and convert them into inorganic substances. Bacteria form activated sludge flakes that float freely in water. The supply of oxygen stimulates the growth of bacteria and thus promotes the formation of activated sludge. Therefore, this biological wastewater treatment process is also known as the activated sludge process.

Wastewater containing activated sludge is discharged to the secondary purification equipment. Here, the flow velocity of the wastewater flow drops again. Precipitation occurs. Activated sludge settles on the bottom of purified water, where it can be separated from the clear water by a mechanical purifier at the bottom. Part of this is transferred to the digestion tower as additional biomass.

The rest of the sludge, also called "return sludge," is returned to the aeration tank to ensure that the aeration tank contains enough microorganisms to break down the sludge. After biological treatment, about 90% of wastewater is free of biodegradable substances. The biological cleaning phase is the most energetic stage of the entire cleaning process, as the oxygen supply is provided by the compressor. Once the water reaches the legally required quality, it can be fed back into the water cycle. For example, it can go back to the river.

In many cases, biological cleaning is inadequate. In these cases, an additional wastewater treatment process is needed-for example, chemical treatment.

Level 3: Chemical wastewater treatment

At this stage of wastewater treatment, chemical processes are used for wastewater treatment. For this purpose, compounds are used to achieve legally specified standard water values. Chemical treatments in sewage treatment facilities include neutralization, disinfection, phosphate precipitation, nitrogen removal, and manganese removal. The specified pH value of is set by neutralization.

Neutralization is achieved by adding an acid (such as HCL) or a base (such as lime milk).

During disinfection, pathogens are killed by adding chlorine or chlorine dioxide. Irradiating wastewater with UV light is a good alternative to adding chemicals, but it is used less frequently.

Phosphate Removal: Our wastewater is often contaminated with phosphates from detergents, fertilizers, food additives and faeces. If they remain in wastewater, they lead to over-fertilization of water and enrichment of nutrients, which can lead to useless, ecosystem-damaging plant growth (eutrophication).

Nitrogen removal is also part of the chemical water purification. Nitrogen is removed by nitrification and de-nitrification. In nitrification, ammonium is converted to nitrite by adding anaerobic bacteria and oxygen, and then converted to nitrate in the second step. Subsequent de-nitrification is also caused by the addition of anaerobic microorganisms. These decompose nitrates into nitrogen gas by enzymatic activity, which is returned to the atmosphere.

Iron Removal: To reduce the iron content of wastewater to specified levels, iron (II) cations are oxidized by the addition of oxygen. Caustic soda must also be added to the wastewater to trigger the oxidation process.

Manganese Removal: Manganese is mainly present in wastewater as manganese hydrogen carbonate. The addition of oxygen produces a sparingly soluble manganese IV compound that can be easily removed from water.

Stage 4: Membrane Process

The membrane and filter process are used in the fourth final wash step. This cleaning step may be combined with a chemical process of precipitation or agglomeration. This creates, for example, an agglutination filtration process. Precipitants and flocculants are added to the wastewater, and the separated substances aggregate. Then pass the wastewater containing the agglutinated material through a cloth or sand filter. Waterslowly penetrates from the filter sheet. Even the smallest suspended solids are removed.

Nano filtration works in a very similar way. However, in contrast to normal filtration, water passes through the membrane under pressure. The membrane also retains the smallest dissolved particles such as molecules and heavy metal ions.

The same thing happens with reverse osmosis. Reverse osmosis uses higher working pressures and finer membranes. Contaminants retained during filtration, Nano-filtration and reverse osmosis are filtered through a primary purification device into sludge treatment as filtered sludge.

Water is now reaching the storage tank, the last area of ??the treatment plant. Here, the water sample is taken again and the water quality is checked. Purified water is fed back into the water cycle only if legally specified parameters are met.

Netsol Water is a manufacturer of all waste water treatment products including STP’s, WTP’s, ETP’s, RO plants, softener plants, etc.

We are just a call away!