How do you create a bar screen in wastewater?

In wastewater treatment, screens are used to filter out coarse materials. At wastewater treatment plants, screening is the first unit activity. To minimise damage and clogging of downstream equipment, pipelines, and appurtenances, screening eliminates items such as rags, paper, plastics, and metals. Coarse and fine screens are used in some modern wastewater treatment systems. Screens are of two types:

a). Coarse Screens

Coarse screens have typically apertures of 6 mm (0.25 in) or bigger and remove heavy particles, rags, and trash from wastewater. Mechanically and manually cleaned bar screens, as well as trash racks, are examples of coarse screens.

b). Fine screens

Fine screens are commonly employed to eliminate particles that could cause difficulties in downstream processes, especially in systems that don't have primary treatment. Fine screens typically have openings ranging from 1.5 to 6 mm (0.06 to 0.25 in).

After coarse or fine screens, very fine screens with apertures of 0.2 to 1.5 mm (0.01 to 0.06 in) can reduce suspended particles to values similar to those produced by primary clarifying.

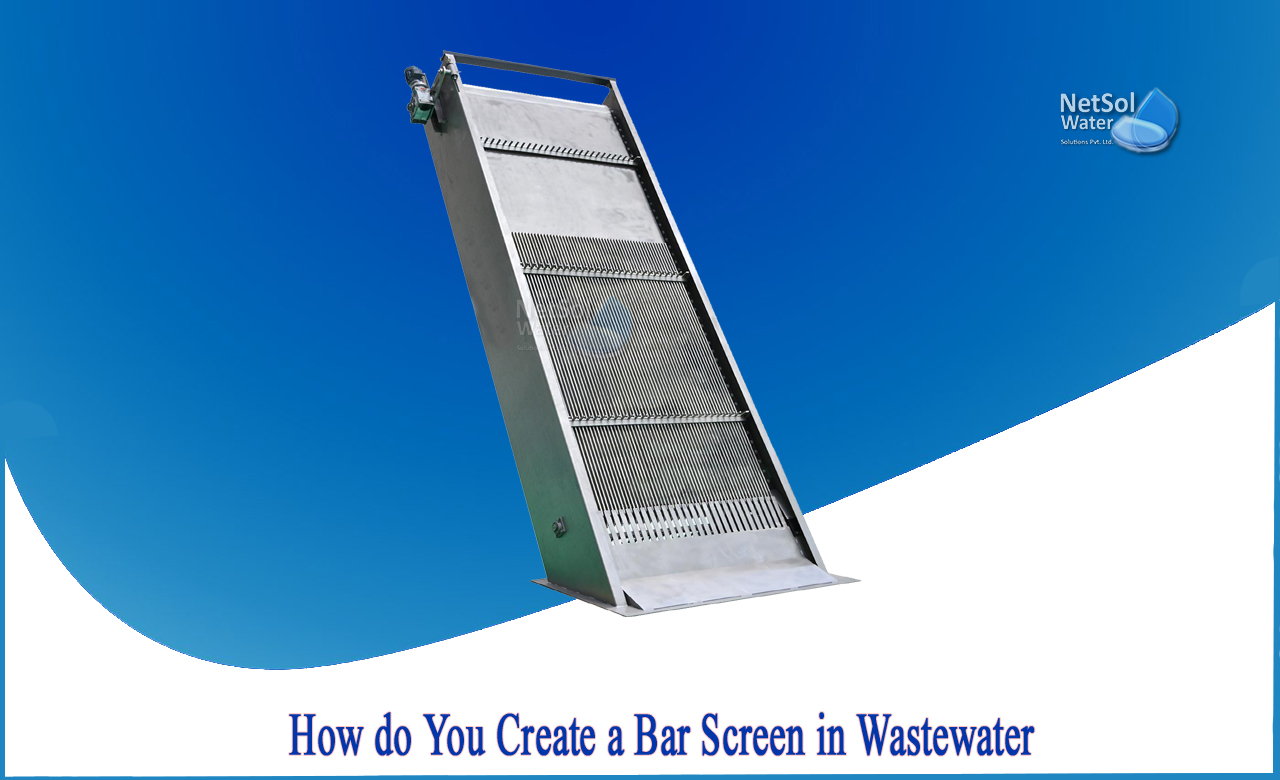

Design considerations for bar screens or bar racks in summary form is given below:

(i) Minimum bar size = 10 mm x 50 mm

(ii) Clear spacing between bars = 15 mm to 75 mm

(iii) Allowable head loss = 0.15 m

(iv) Minimum approach velocity = 0.3 m/s

(v) Velocity of flow through screen openings= 0.6 m/s to 1.2 m/s

(vi) Slope with horizontal-

(a) Manually cleaned = 45° to 60°

(b) Mechanically cleaned = 60° to 90°

Design of bar screens:

Step wise calculation of following quantities is presented as:

1. Cross section of bar screens

The continuity equation is used to calculate the cross section of the bar screen channel:

Qd = AcVa

Ac= Qd / Va

Qd = design flow in m3 /s, Va = Velocity in the approach channel in m/s, W= channel width in m, d = water depth in the channel in m,Ac = channel cross section in m2

Usually, rectangular channels are used, and the ratio between depth and width is taken as 1.5 to give the most efficient section: d/W = 1.5

2. The head loss through the screens is given as

HI = (V2b – Va2) / 2g * 1/ 0.7

HI = head loss, Va = approach velocity, m/s, Vb = Velocity through the openings in m/s,

g = acceleration due to gravity, m/s2

3. Cross section of the bar screen is given by following equation

As = Ac / sinq

As = bar screen cross section, m2, q = inclination angle of the screen.

4. Net area of the bar screen available for flow is given by the following equation

Anet = AS *(S / S + tbar)

S = space between bars in m, tbar= thickness of the screen bars in m

5. Number of bars in the screen is given by the following equation

n tbar + (n-1)S = W

Following all the steps provided above, one can easily go into the designing of bar screens.

For more information, contact Netsol Water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.