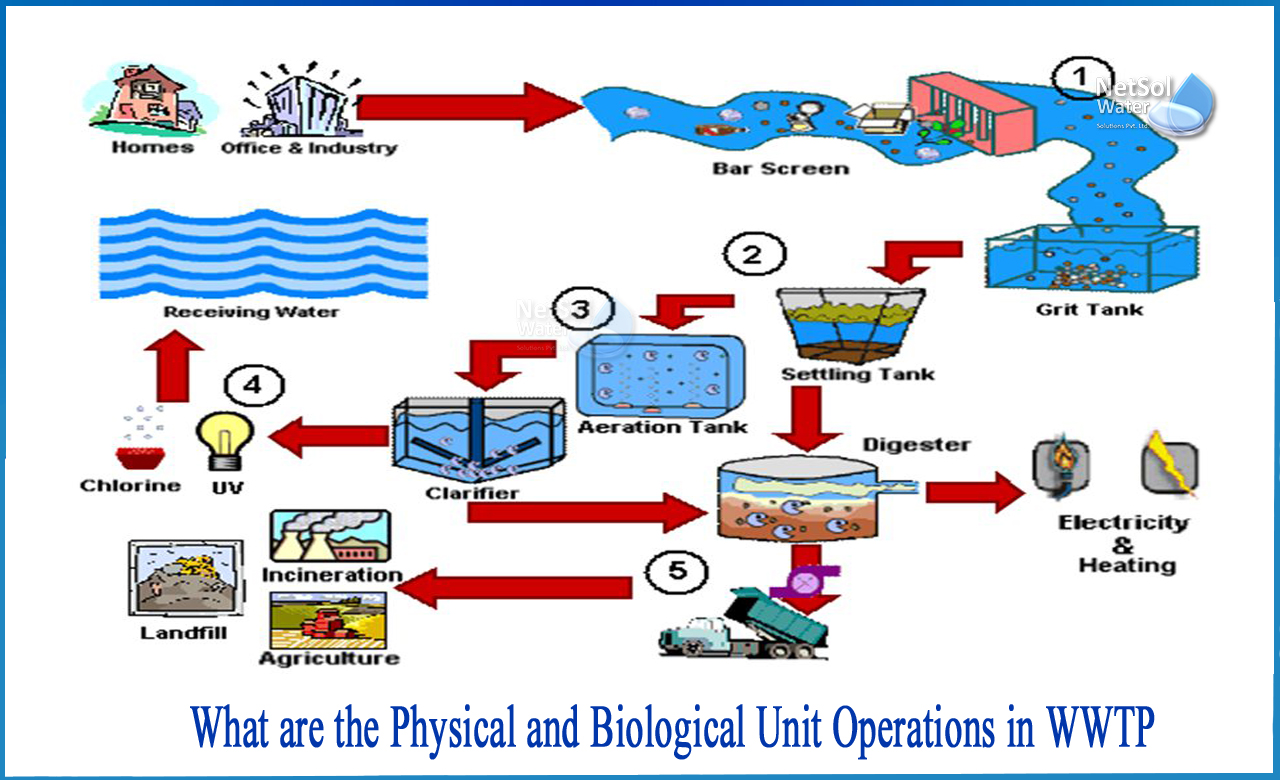

What are the Physical and biological unit operations in WWTP?

Unit operations are physical operations to remove pollutants present in water and wastewater, and unit processes bring pollutants into a state of matter so that they can be easily removed by physical, chemical or biological processes. Both have the specific use of coalescing fine colloidal particles and increasing their size, to remove them from water or wastewater.

Various unit operations

· Physical Unit processes

· Chemical unit processes

· Biological unit processes

Physical unit operations in wastewater treatment

Sifting, mixing, agglomeration, sedimentation and gravity separation are some basic physical operations in wastewater treatment.

Various physical unit operations are applied to separate materials such as sand, stones and PET bottles. When these types of materials enter the rest of the processes, the further treatment steps or equipment’s are interrupted.

1: Screening in wastewater treatment process

Sifting/ screening is used to remove large particles in the wastewater streams. This prevents large particles in the wastewater from causing damage to the process equipment’s (for example, large particles can damage the pump used to treat the wastewater). It also improves process safety and effectiveness.

2: Mixing and agglutination

Mixing is an important step of wastewater treatment. Mixing is used to mix chemicals with wastewater to agglomerate particles and achieve good heat transfer.

In-line mixers, high-speed in-line mixers, water jet paddle mixers and turbine mixers are some of the mixers used in wastewater treatment.

Aggregation is the process of forming large particles that can be removed by sedimentation or filtration of small destabilized particles. Some chemicals are used to destabilize particles in wastewater, a process called as coagulation. When these small destabilizing particles are mixed, random movements occur. These particles collide and adhere to form large particles known as micro-flocculation or micro-flocs.

3: Gravity separation

Gravity separation is the most common process in wastewater treatment. Gravity separation technology is used in settling tanks and septic tanks, to separate suspended solids that are denser than water.

Biological unit operations in wastewater treatment

Biological wastewater treatment is an important and indispensable step in wastewater treatment systems, treating wastewater from residential, commercial or industrial facilities. This is often referred to as the secondary treatment process and is used to remove contaminants left over after the primary treatment.

Biological treatment uses microorganisms to break down the pollutants in the wastewater. This treatment relies on bacteria, nematodes, algae, fungi, protozoa and rotifers to break down unstable organic waste into stable inorganic forms using normal cellular processes.

The process of biological treatment of wastewater can be divided into two main types:

1. Biological aerobic treatment (in the presence of oxygen).

2. Biological anaerobic treatment (in the absence of oxygen).

Aerobic wastewater treatment is a biological process performed in the presence of oxygen. This is the fastest and most efficient biological wastewater treatment step that removes up to 98% of organic pollutants. This process effectively decomposes organic pollutants, resulting in cleaner wastewater than anaerobic treatment.

1: Activated Sludge Process:It is the most widely used biological process in secondary stage of wastewater treatment. The process refers to a multi-chamber reactor unit that uses high concentrations of microorganisms to break down organic matter and remove nutrients from wastewater to produce high quality wastewater.

In this process, wastewater containing microorganism is aerated (by a mechanical aeration device) and organic matter is aerated in the aeration tank. This process accelerates the decomposition of waste. Aeration in the activated sludge process relies on pumping air into the basin, which promotes the growth of microorganisms in the wastewater.

The effluent from the aeration tank, which contains a cotton-like microbial mass called sludge, is separated in a settling tank, sometimes called a secondary purification device. This process is a very compact, inexpensive and efficient biological treatment system for wastewater treatment

2: Drip Filter: This is the second most common type of aerobic treatment. These filters are commonly used to remove compounds such as ammonia from wastewater after the primary treatment.

3: Aerated Lagoons: It is the aerobic biological wastewater treatment process. The effluent may be used or reused for recharge. The settled sludge requires further treatment.

4: Oxidation Pond: The pond is a site of interaction between bacteria, algae and other organisms which feed on the organic matter received from primary effluent. These ponds also increase productivity because they produce wastewater that can be used for other purposes. Overall, the process is slow and requires a lot of land. Oxidized ponds are typically used in low-population areas where land is readily available.

Technical assistance and guidance

Netsol Water collaborates with a wide range of international organizations to tackle complicated problems by strategically integrating modern treatment technology with practical solutions. We provide solutions for water, wastewater, air, solid waste disposal, among other services in commercial as well as industrial facilities.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.