What is trickling filters explain?

A trickling filter is an attached growth technique, in which the microorganisms that treat the water are attached to an inert packing material. Rock, gravel, slag, sand, redwood, and a variety of plastic and other synthetic materials are among the packing materials utilized in attachment growth techniques.Treatment of sewage or other wastewater with trickling filters is one of the most well-known and well-established treatment methods.

A trickling filter is also known as a trickling bio filter, a biological filter, and a biological trickling filter. Roughing filters, intermittent filters, packed media bed filters, alternative septic systems, percolating filters, attached growth processes, and fixed film processes have all been used to characterize these systems.Specialized trickling filters with plastic media and high flow rates may be used to clean industrial effluent. Trickling filters have been used to treat wastewater from a range of industrial processes.

There are two types of industrial wastewater trickling filters:

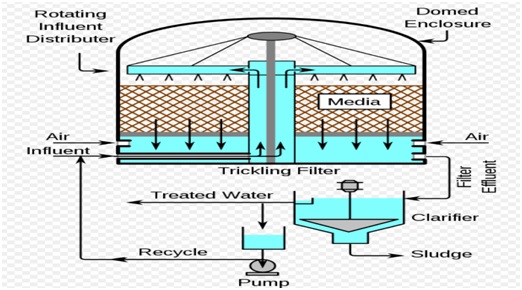

>Plastic packing or other media are placed in large tanks or concrete containers. Plastic packing or other media is stacked vertically in towers.Because of the low cost of plastic tower packing’s, they've been used as trickling filter beds in towering towers as high as 20 meters.As with other trickling filter applications, the treated water effluent from industrial wastewater trickling filters is often handled in a clarifier to remove the sludge that sloughs off the microbial slime layer adhering to the trickling filter medium.

>Aerated bio filters using plastic media in vessels using blowers to inject air at the bottom of the vessels, with either downflow or up flow of the wastewater, are some of the most recent trickle filter technologies.

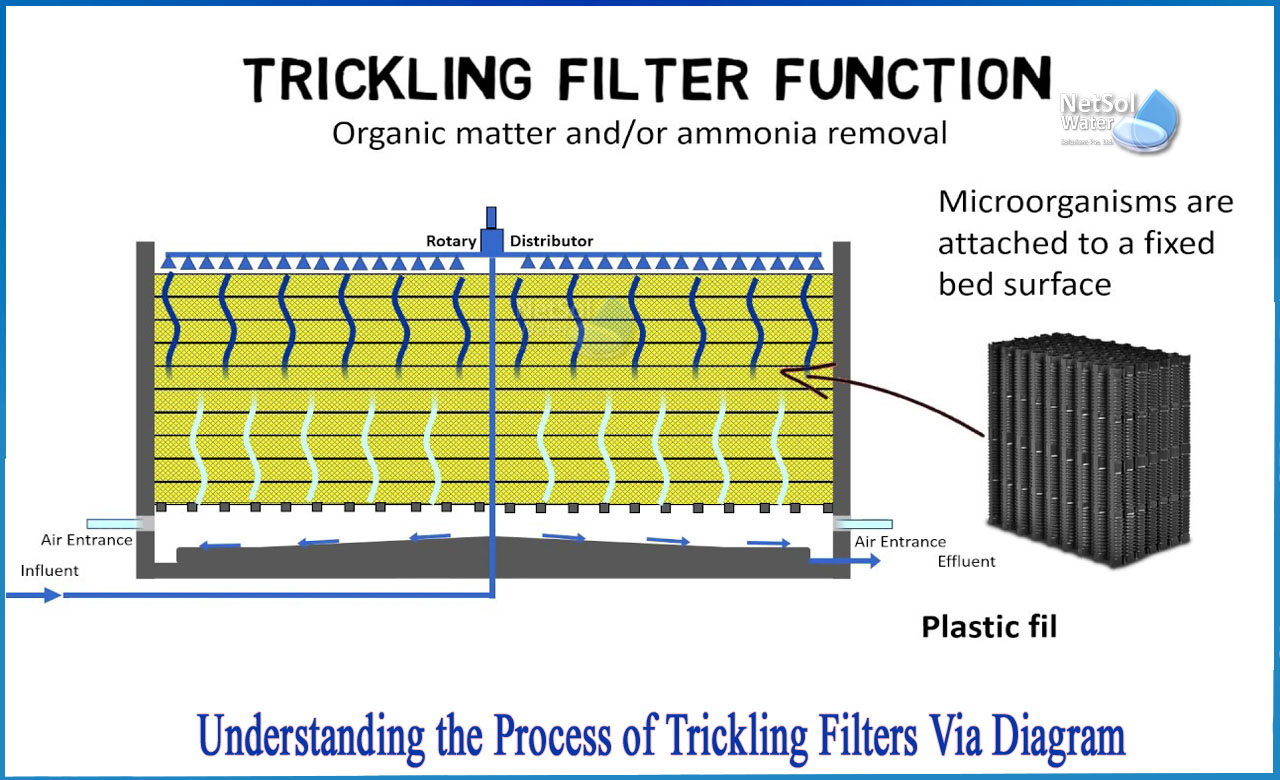

Essential elements of a comprehensive trickling filter system:

>A layer of microbial slime is fostered and formed on a bed of filter material;

>A container or enclosure that houses the filter media bed;

>A system for evenly dispersing wastewater flow over the filter medium; and

>A sludge removal and disposal system for the treated effluent.

Description of the procedure:

1) In a trickling filter, wastewater is spread over the top of a tank containing non-submerged packing material.

2) The bacteria forming as an attached biofilm require oxygen, which is provided by air circulation in the empty area, either by natural draught or by blowers.

3) During operation, the biomass connected to the medium metabolizes the organic material present in the wastewater. As organic matter extracted from flowing wastewater is synthesized into new cellular material, the biological slime thickens.

4) The depth of oxygen penetration into the microbial layer limits the thickness of the aerobic layer.

5) As a result of the increasing thickness of the slime layer, the microorganisms near the medium face enter the endogenous phase as the substrate is metabolized before it can reach them, and they lose their capacity to cling to the media surface. The liquid then washes the slime off the medium, prompting the growth of a fresh slime layer. Sloughing is the term for the process of shedding the slime layer.

6) An underdrainage collects the sloughed-off film and treated wastewater while also allowing air to circulate via a filter. The collected liquid is pumped into a settling tank to separate the solids from the liquid.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.