What are the Challenges in Brackish Water Treatment with RO Technology?

Brackish water contains dissolved salts like sodium, calcium, magnesium, and chloride at concentrations above drinking water standards but below seawater. Brackish groundwater and surface water pose unique treatment challenges due to their mid-range salinity. Reverse osmosis (RO) has become the leading technology for desalinating brackish water for municipal and industrial applications. However, optimizing RO systems for brackish water requires strategies to address common challenges.

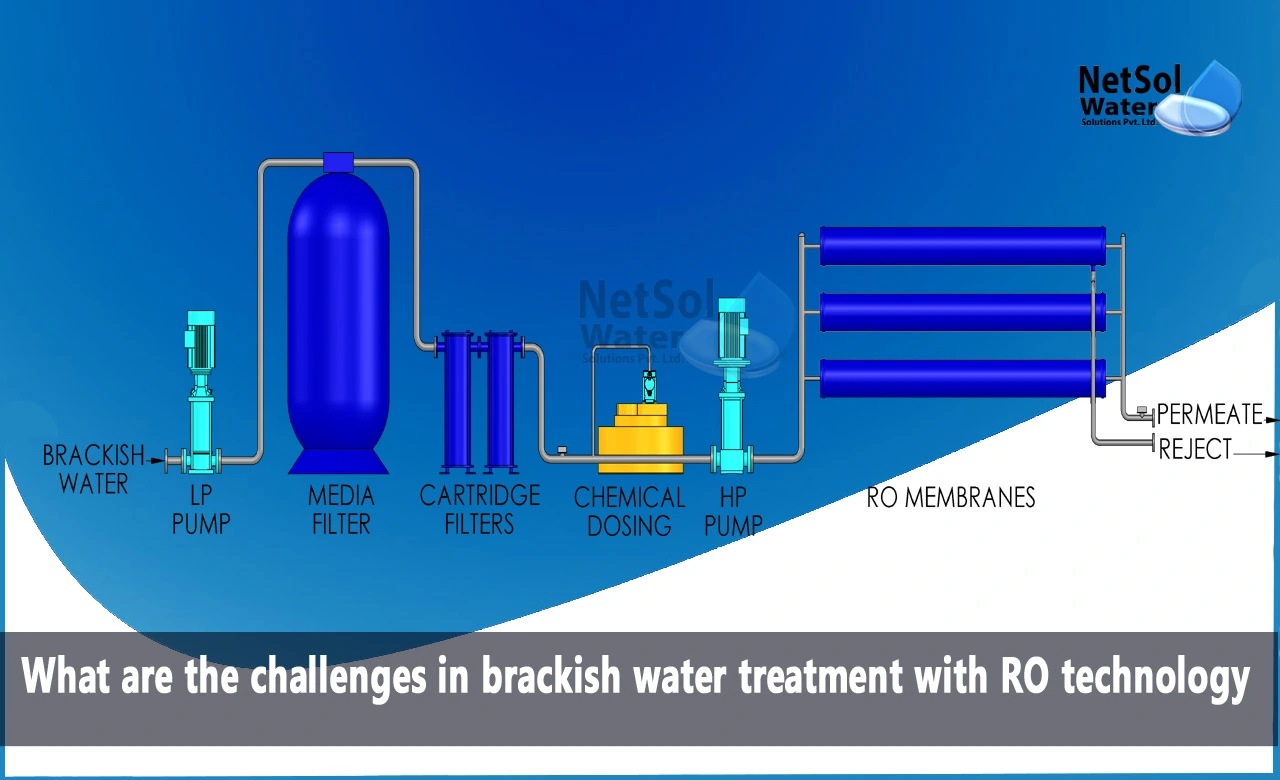

Pretreatment Requirements

Proper pretreatment is critical prior to the RO unit to prevent fouling and scaling on membrane surfaces. Brackish water often contains high levels of silt, organics, bacteria, and hardness ions that can impair RO performance. Pretreatment steps include filtration, softening, disinfection, and acidification.

Multi-media filtration effectively removes suspended solids and particulates down to 10-20 microns. The addition of filter aids like coagulants and flocculants improves removal of colloids and organic matter. Softening precipitates out hardness ions that contribute to scale formation. Disinfection prevents bio fouling from bacteria accumulation while oxidation destroys organic contaminants. Acidification helps solubilize iron, manganese, and silica species.

While seawater RO units usually require 2-3 pretreatment steps, brackish water RO may need 4 or more for adequate fouling control. The expense of additional pretreatment must be balanced with the lower chemical costs of RO operation.

Scaling and Fouling Control

The most problematic RO contaminants in brackish water are calcium carbonate, calcium sulfate, barium sulfate, and silica, which precipitate as tenacious scale deposits on membrane surfaces. Silt, microorganisms, and organic matter are also major fouling concerns.

Proper pre saturation by adding acid or CO2 helps prevent carbonate scaling. Adding sulfate or phosphonate anti scalants inhibits sulfate scales. Operating at lower recoveries and higher crossflow velocities minimizes concentration polarization. More frequent cleanings are required, using acidic and alkaline cleaners to remove organic and inorganic films.

Advanced membrane materials like thin-film composites better withstand fouling and scaling. Zeeweed UF pretreatment membranes remove colloids and organics before RO. Inter stage addition of antiscalants also helps.

Element Design Factors

RO elements for brackish water typically operate at lower pressures (100-150 psi), have larger diameter spacer-filled channels, and utilize thicker feed spacers compared to seawater elements. This improves silica removal and reduces fouling risks, but compromises packing density.

Brackish water RO systems thus use interlocking pressure vessel housings to accommodate the larger elements. Non-cylindrical stacks are also an option for maximizing membrane area. Careful element selection and vessel design is needed to optimize performance.

Permeate Quality Requirements

While seawater RO systems must achieve 99% salt rejection, brackish water RO may only need 90-98% rejection depending on the application. Lower rejection reduces osmotic pressure requirements and power consumption.

For drinking water applications, 99% rejection of ions may still be needed to achieve total dissolved solids (TDS) under 500 mg/L. Higher rejection elements made with newer membrane materials can achieve this efficiently.

For industrial process uses like power plants, tighter salt removal is not critical. Relaxing permeate quality standards allows cost savings through more flexible RO design.

Recovery Limitations

Recovery refers to the percentage of purified water produced relative to the feed volume. For brackish water, recoveries are limited to 50-85% to control scaling. Higher salinity feed water requires lower recovery rates.

Single-pass systems produce lower recovery since concentrate is wasted after one pass through the RO bank. Two-pass designs recycle the concentrate to boost recovery rates to 75-85% range. However, the higher TDS in two-pass systems increases the likelihood of scale formation.

Elevated scaling risks often favor single-pass designs for brackish water despite the lower recovery. Multi-stage designs are another option allowing intermediate antiscalant dosing.

Energy Efficiency

Since brackish water RO operates at lower pressures, energy requirements are reduced relative to seawater systems. Further energy savings can be achieved by:

- Optimizing RO pump size to match required pressure conditions

- Using high-efficiency pumps (90% vs. 70% efficiency)

- Installing energy recovery devices (~50% reduction in energy demand)

- Operating at lower average flux rates

- Minimizing element fouling through enhanced pretreatment

Energy costs for brackish water RO are in the range of 0.3-0.5 kWh/m3, about 75% lower than seawater RO. Overall water costs are also reduced by the lower chemical expenses for brackish operation

Concentrate Management

Unlike seawater RO with 60-70% recovery, brackish water systems produce larger volumes of concentrated brine that must be properly disposed. Concentrate disposal options include deep well injection, lined evaporation ponds, and piped discharge for inland plants. Seawater blending and brine crystallization are also used.

Environmental regulations on salinity and chemical content of discharge must be met. Pretreatment to reduce contaminants of concern may be required. Mechanical vapor compression units help minimize discharge volumes.

Addressing the unique challenges posed by mid-range salinity brackish water requires tailored strategies in RO system design and operation. With appropriate pretreatment, element selection, energy optimization, recovery rate, and concentrate disposal, brackish water RO can produce high purity water at lower costs than seawater desalination. Continued advances in membrane materials, fouling resistant elements, and system engineering provide solutions to enhance the cost-competitiveness of brackish water RO.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.