Overview

The following chemicals solve the problem of adjusting the alkalinity of plants:

· Magnesium hydroxide

· Lime sludge

· Soda

· Caustic soda

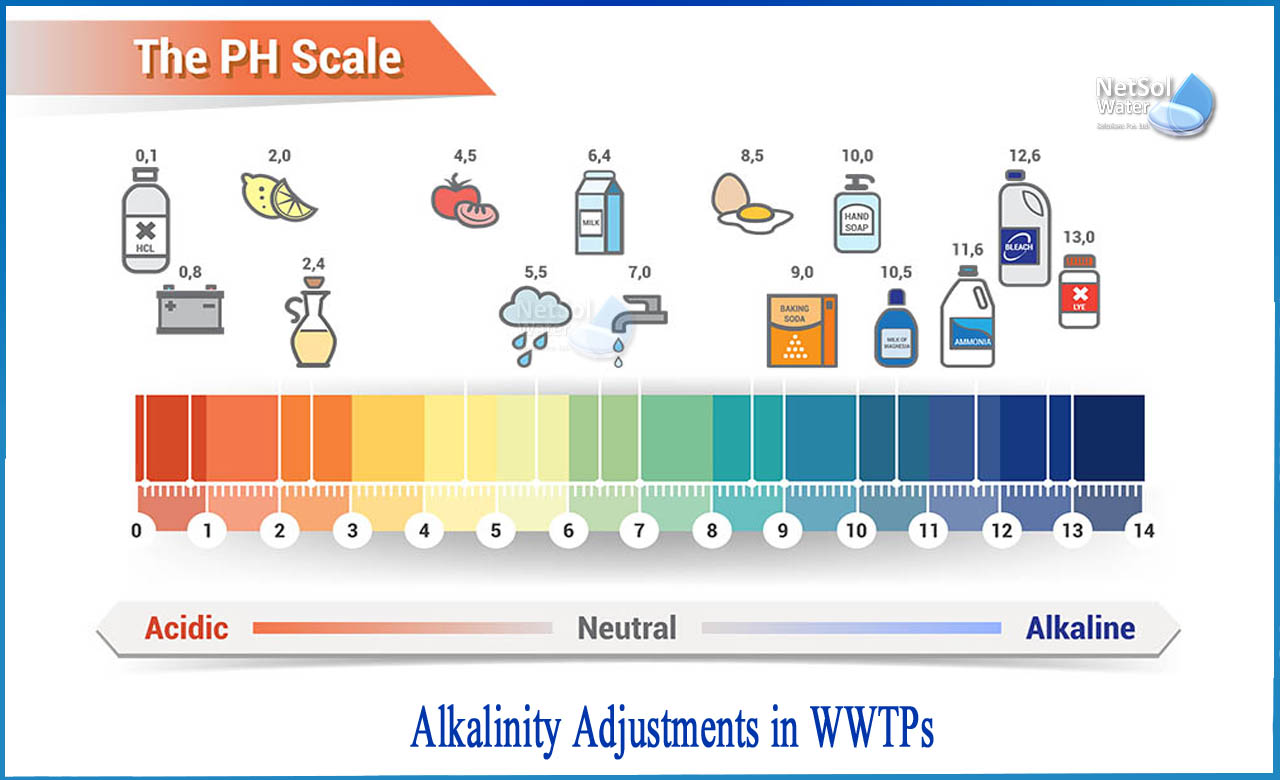

Ultimately, the choice depends on the final requirements of the facility and is determined by the facility's emission permit. Most wastewater treatment plant operators know that wastewater treatment plants need the lowest levels of alkalinity to function optimally at ideal pH and keep microorganisms happy. However, the pH and alkalinity values ??are often misused interchangeably, and the translation loses a complete understanding of the true relationship of each parameter to biological stability and optimal performance.

How to control alkalinity in the wastewater treatment plants?

In most cases, this term error is due to the use of the most common alkaline pH regulators and additives, caustic soda and lime. If their use successfully meets the pH requirement, it may not be possible to meet reasonable alkaline requirements without adversely raising the pH beyond biologically healthy limits. Moreover, it is virtually impossible to maintain pH stability and uniformity across the processing tank. Therefore, it is important to review each pH and alkalinity adjustment option and fully understand how each affects your system. Looking at the nitrification process, for example, it has been reported that stable, slightly elevated pH and sufficient alkalinity significantly improvesde-nitrification of wastewater.

pH Adjustment

Lime: A very common product, also known as slaked lime or quicklime can be "slurred" by adding water to the dry lime powder. This slurry can be used to treat waste water to increase pH and alkalinity, and is commonly used in drinking water to "soften" or remove hardness minerals such as calcium and magnesium from drinking water.

Lime sludge minimizes the effects of sediments that may deposit on the distribution system. It is also the most widely used product for maintaining alkaline levels due to its low cost and multiple treatment benefits, including support in removing manganese and iron from water.

The disadvantage of lime sludge is its high solubility. Maintaining proper pH levels is often biologically exorbitant before achieving ideal levels of alkalinity and process stability. Another major problem is that lime slurries increase waste sludge by up to 50%, resulting in higher operational waste costs. Adding slaked lime sludge to the collection system, as if that were not enough, increases the operational and maintenance costs associated with lime accumulation and solid/sludge accumulation. In severe cases, this can lead to line blockage.

Caustic soda: Caustic soda is commonly referred to as sodium hydroxide or NaOH. Surprisingly, it is widely used in the home, but in the industrial sense it is mainly used for alkali neutralization. Caustic soda comes in a variety of concentrations and is a common method for neutralizing and tame all types of acids. It is also considered easy to install in the system due to its solubility.

However, at high concentrations, handling is extremely dangerous and some precautions must be taken for safe use in the processing. This includes at least an improved PPE (Personal Protective Equipment) and readily accessible cleaning area.

Like the lime slurry, the high solubility of caustic soda often makes pH values ??biologically unacceptable. This often increases the risk of microbial burning (increasing pH) before making adjustments. In addition, it is important to pay attention to the relationship between temperature and the amount of caustic alkali in the solution. At concentrations above 50%, the freezing point is 60 ° F, limiting its use to warmer climates and requiring a heating tank. Using a low percentage of caustic soda lowers the freezing point and alleviates some of these concerns, but shipping the "moisture content" of the mix requires paying more freight.

The cost will be high. Finally, this is generally explained, depending on the current market value and location of shipment, especially given the relative dosage and alkalinity shipped per pound of product.

Soda Ash: The most expensive of the three options is soda ash.Alkalinity and pH can be dramatically increased and controlled by using baking soda ash (sodium carbonate), which has little effect on the overall pH. If you are trying to raise the pH level, soda ash is the right choice with the guidance of the water treatment process.

Magnesium hydroxide: Magnesium hydroxide, also known as magnesia milk, is the main function of the product toneutralize acids and stabilize alkalinity. Magnesium hydroxide is self-buffering, so you generally don't have to worry about adjusting its alkalinity. Magnesium hydroxide only dissolves and produces a pH of up to about 8.5. This virtually eliminates the possibility of bioactive burnout (pH 9 and above), making this chemical safe to use.

Magnesium hydroxide has some drawbacks.

The slurry (usually 60-66%) separates and must be constantly mixed or agitated. This problem can be solved easily and without worry by choosing the right equipment to prevent it. Magnesium hydroxide is the most difficult of the options presented, but it’s alkaline and pH stability advantages provide more stable reaction times, and its self-buffering properties provide an environment in which wastewater treatment organisms can operate. It will be more stable.

Conclusion

All the above mentioned chemicals can control alkalinity in the wastewater treatment plants.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.