Dead-end filtration or cross-flow filtration are the two primary types of filtration techniques, which may be used in industrial applications. To achieve higher levels of filtration, cross-flow filtration is frequently employed in conjunction with reverse osmosis and ultrafiltration.

Thus, choosing the right system for a particular application can be aided by being aware of the variations between different filtration techniques, and by knowing the advantages of cross flow filtration over dead end filtration.

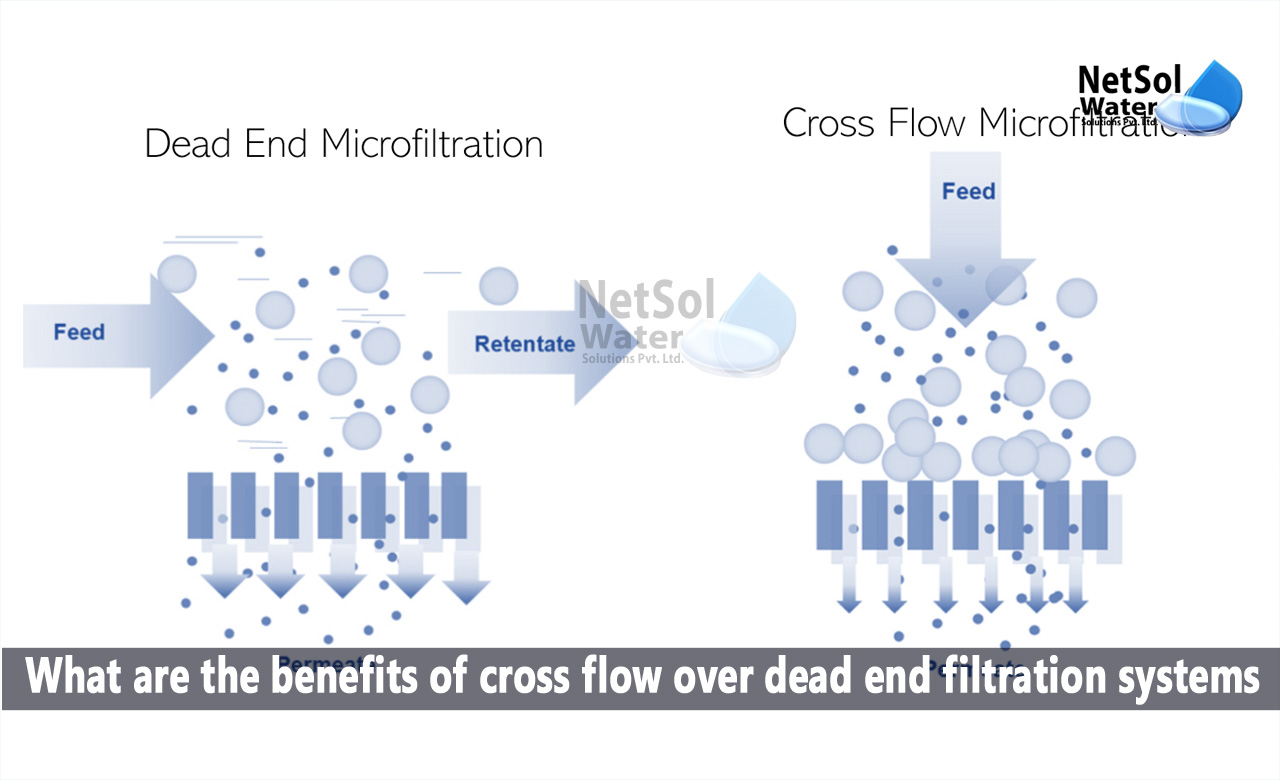

Here is a summary of cross-flow and dead-end filtration's features.

· Cross-Flow filtration systems

The process fluid that needs to be filtered in cross-flow filtration systems flows tangentially, over the membrane filter rather than through it. By allowing the filter cake to wash away during filtration, the system is able to avoid blockages and maintain constant flow levels for a longer length of time. Depending on the filter membrane's pore size, the procedure is either cross-flow microfiltration or ultrafiltration.

· Dead-End filtration systems

Dead end filtration separates solids from liquids that flow vertically into the filter. On the filter's surface, the filtered materials solidify into a cake, quickly blocking the membrane.

Dead-end filtration systems need a booster or vacuum pump that can provide the force, necessary to generate the right flow rate in order to overcome the membrane's resistance. Dead-end filtration, unlike cross-flow filtration systems, requires periodic membrane cleaning or replacement, in order to retain peak performance.

What are the benefits of cross-flow filtration over dead-end filtration systems?

Cross-flow filtering is superior for a larger range of industrial applications, although dead-end filtration has some advantages for straightforward, small-scale operations. Cross-flow filtration systems provide the following advantages:

The capacity to clean surface accumulation from the membrane

Absence of a filter assists a longer lifespan for the filter media, because there is less accumulation, and filter cake prevents the membrane from becoming permanently fouled.

Implement these strategies if you want cross-flow filtering systems to function even better:

ATF: Alternating tangential flow (ATF) is a production technique that uses a diaphragm pump, to remove clogged particles from the filter membrane and stop permanent fouling.

Clean-in-place (CIP) systems: These remove fouling from filter membranes after extended periods of use. Alkalis, acids, and reactive chemicals are frequently used in CIP systems. If these systems make use of bleach or sodium hypochlorite, you will need to take this substance out of some feeds for membrane plants.

Over time, the oxidising effects of bleach harm membranes and finally necessitate membrane replacement. The majority of systems, nevertheless, use acids or caustics for CIP, which, when used at the proper pH and temperature, will stop degradation.

Concentration: Decreased liquid volume results from enabling permeate flow. Particles larger than the membrane's pores will be retained by the system and concentrated.

Diafiltration: In bioprocessing applications, diafiltration can happen after concentration. By using fresh solvent to replenish the permeates volume, this procedure helps remove permeate components from the filtered material. In order to maintain a constant flow volume, the rate should be the same as the permeate flow rate.

Process flow disruption (PFD): It is an efficient substitute for backwashing. While, less effective than backwashing at preventing fouling, it includes releasing the transmembrane pressure by briefly closing the permeate outlet.

Get your water purification systems from experts!

Netsol Water provides design and manufacturing services to create a unique water filtration system. Whether you require a cross-flow filtration system or a dead-end filtration system, we will assist you in selecting the best solution as per your need and requirement.

Contact us right now to find out more about our water treatment products and services. All kinds of chemical, physical, and biological impurities can be effectively eliminated, by our water treatment systems. For further information or to make a product purchase, contact us at +91-9650608473 or drop a mail at enquiry@netsolwater.com