Overview

The practise of adding air to wastewater to allow aerobic biodegradation of organic compounds is known as aeration. The trickling filter and the activated sludge process are the most common secondary treatment methods, and they are often classed as fixed-film or suspended-growth systems, respectively.

Trickling Filter

Trickling filters, built wetlands, and rotating biological contractors are among the fixed-film systems. Bacteria develop on media such as stones or reeds in these systems, and as sewage travels over them, the bacteria get to work eating the organic debris. The bacteria's activity will be stimulated by the addition of oxygen. The resulting 'purified' water is pumped via pipes to be treated further.

Activated Sludge Process

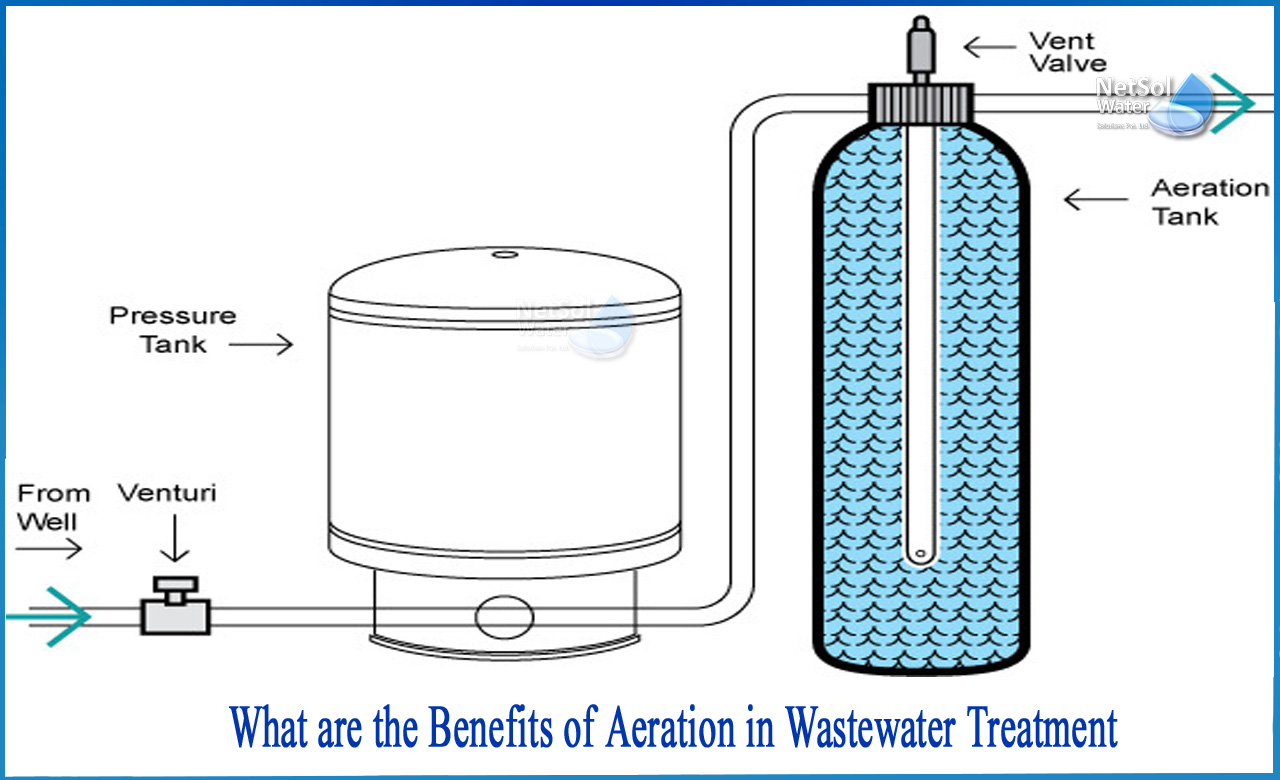

The activated sludge process is one of the suspended-growth processes. This is where the sewage is poured into an aeration tank and mixed with air and bacteria-laden sludge. It is then left for several hours to allow the bacteria to break down the organic waste into harmless by-products. Returning the sludge to the aeration tank for mixing with air and new sewage will activate it once more with billions of bacteria and other small organisms.The partially treated effluent is then sent to a sedimentation tank to be cleaned of any remaining microorganisms.

These processes require a sufficient and uniformly distributed supply of air to function properly.Bacteria will not be able to break down incoming organic stuff in a timely manner if there is insufficient oxygen. Not only will the procedure be sluggish, but it will also result in septic conditions that can turn poisonous and make pollutant removal much less efficient.

When is it necessary to use aeration?

Aeration is an element of the secondary treatment process in municipal and industrial wastewater treatment. In secondary treatment, activated sludge is the most prevalent method. Pumping air into a tank, which promotes microbial growth in the wastewater, is the basis of aeration in an activated sludge process.

The microorganisms feed on the organic materials and create flocks that are easy to separate. The bacteria that produce the "active sludge" flocks are constantly recirculated back to the aeration basin after settling in a separate settling tank to speed up decomposition.

What is the Process of Aeration?

Bacteria need oxygen to clean and stabilise wastewater, thus aeration helps.

The bacteria require oxygen to allow biodegradation to take place. Bacteria in the wastewater use the oxygen to break down carbon-containing organic debris, producing carbon dioxide and water. Bacteria can't biodegrade incoming organic stuff in a suitable amount of time if there isn't enough oxygen. In the lack of dissolved oxygen, degradation must take place in septic conditions, which are sluggish, smelly, and result in incomplete pollutant transformations. Some biological processes convert hydrogen and sulphur to generate hydrogen sulphide and carbon to methane under septic conditions.

What are the Benefits of Aeration in Wastewater Treatment?

Aeration is the most important part of a treatment system that uses activated sludge. The level of wastewater treatment achieved by a well-designed aeration system is directly proportional to its design. The key to quick, economically viable, and successful wastewater treatment is a sufficient and evenly distributed oxygen supply in an aeration system. The Membrane Aerated Biofilm Reactor is a water treatment game changer.

Conclusion

A well-designed aeration system has a direct impact on wastewater treatment efficiency. Reducing the time it takes to complete the process, boosting energy efficiency, and lowering expenses. This is where Netsol can help, as we are among the leading providers of waste water treatment plants and we do a promising care of the aeration related equipment as we are aware about the importance.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.