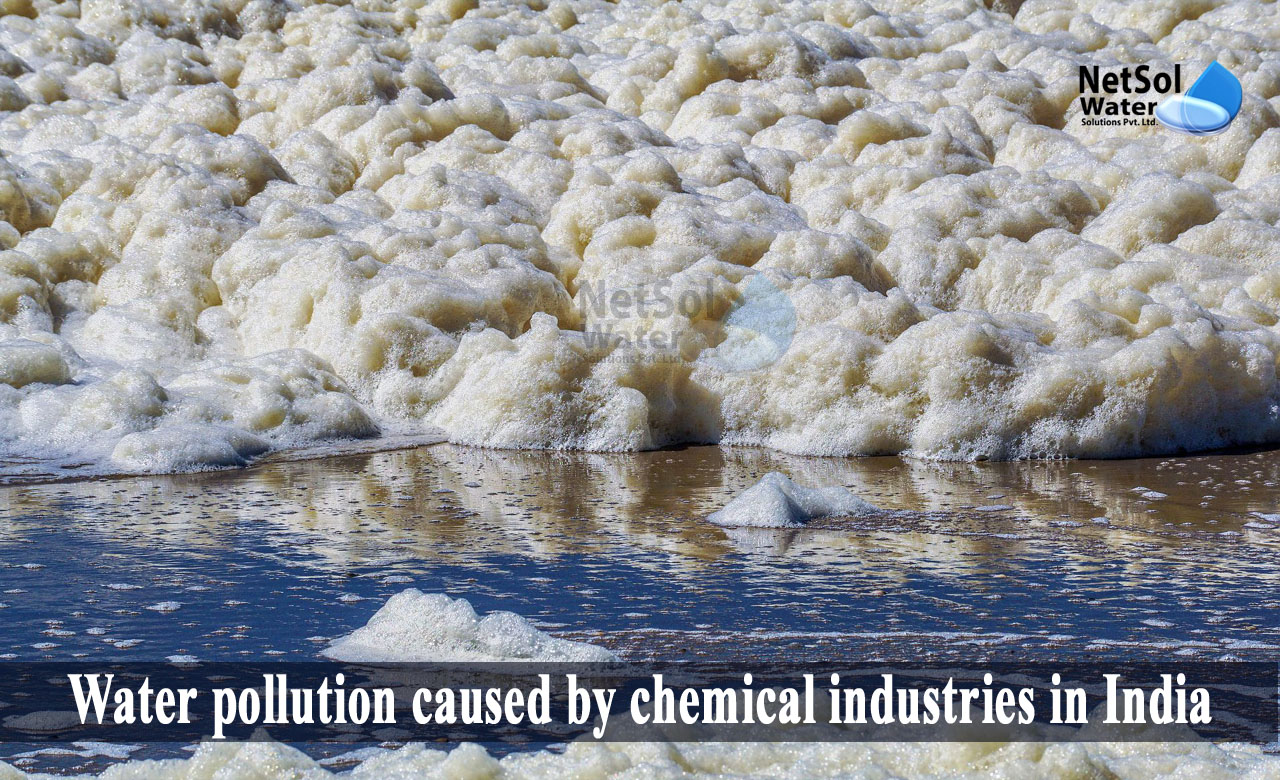

The chemical industry is significant in terms of its environmental impact. This industry's wastewaters are generally strong and may contain toxic pollutants. In general, treating highly contaminated and toxic industrial wastewater at the source is the best strategy.

Let’s see the effect of water pollution caused by chemical industries in India, and their effective treatment.

Wastewater produced by chemical industries

Organic and inorganic matter are commonly found in varying concentrations in chemical industrial wastes. It contains acids, bases, toxic materials, and matter that are high in biological oxygen demand, and colour.

Many chemical industry materials are toxic, mutagenic, carcinogenic, or simply not biodegradable. The use of surfactants, emulsifiers, and petroleum hydrocarbons in the chemical industry, reduces the performance efficiency of many treatment unit operations.

How to solve Water pollution caused by chemical industries?

The wastewater can be treated by biological oxidation methods, which include trickling filters, rotating biological contactors (RBCs), activated sludge, or lagoons, etc.

· Trickling Filters

The effluent for primary treatment is sprayed or trickled over the filter. A rectangular or circular bed of coal, gravel, Poly Vinyl Chloride (PVC), broken stones, or synthetic resins is typically used, in the filter.

On the surface of the filter medium, a gelatinous film composed of microorganism’s forms. These organisms contribute to the oxidation of organic matter in the effluent, to carbon dioxide and water.

· Aerated Lagoons

These are some of the most common biological treatment processes. This is a large holding tank lined with rubber or polythene, in which the effluent from the primary treatment is aerated for 2-6 days, and the formed sludge is eliminated.

· Ozone/AOP technologies

Today, ozone and UV are well known and proven in the field of water and wastewater treatment, with ozone as a multifunctional powerful oxidant and UV as the best available disinfection technique, in terms of treatment results, plant design, and cost.

The primary goal of these combined processes is to increase the potential for oxidation.

· Electrodialysis

Electrodialysis is a method of electrochemical membrane separation for ionic solutions, which has been used in industry for decades. It can be used to separate and concentrate salts, acids, and bases from aqueous solutions, as well as to separate monovalent ions from multivalent ions and ionic compounds from uncharged molecules.

· Adsorption

This method is used to eliminate colour and other organic pollutants from effluent. The process also removes toxic chemicals that conventional treatment methods cannot remove.

· Equalization

Effluent treatment plants are typically designed to treat wastewater with a more or less constant flow, and a quality that varies only slightly. The equalization tank overcomes this by collecting and storing the waste, allowing it to mix and become of consistent quality, before being pumped at a constant rate to the treatment units.

Conclusion

The chemical industry's impact on the world can be devastating, but there are ways to mitigate its environmental impact. Several large corporations like Netsol Water are working to reduce its negative effects on the environment.

How can we assist?

Netsol Water has aided in the resolution of hundreds of water-related problems, by utilizing a wide range of specialized water treatment and wastewater treatment technologies, in chemical industries of India.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.